Fume exhaust ventilator and range integrated machine

An all-in-one machine and range hood technology, which is applied in the direction of removing oil fume, household stoves, household appliances, etc., can solve the problem of no obvious effect, etc., and achieve the effect of good oil leakage prevention and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

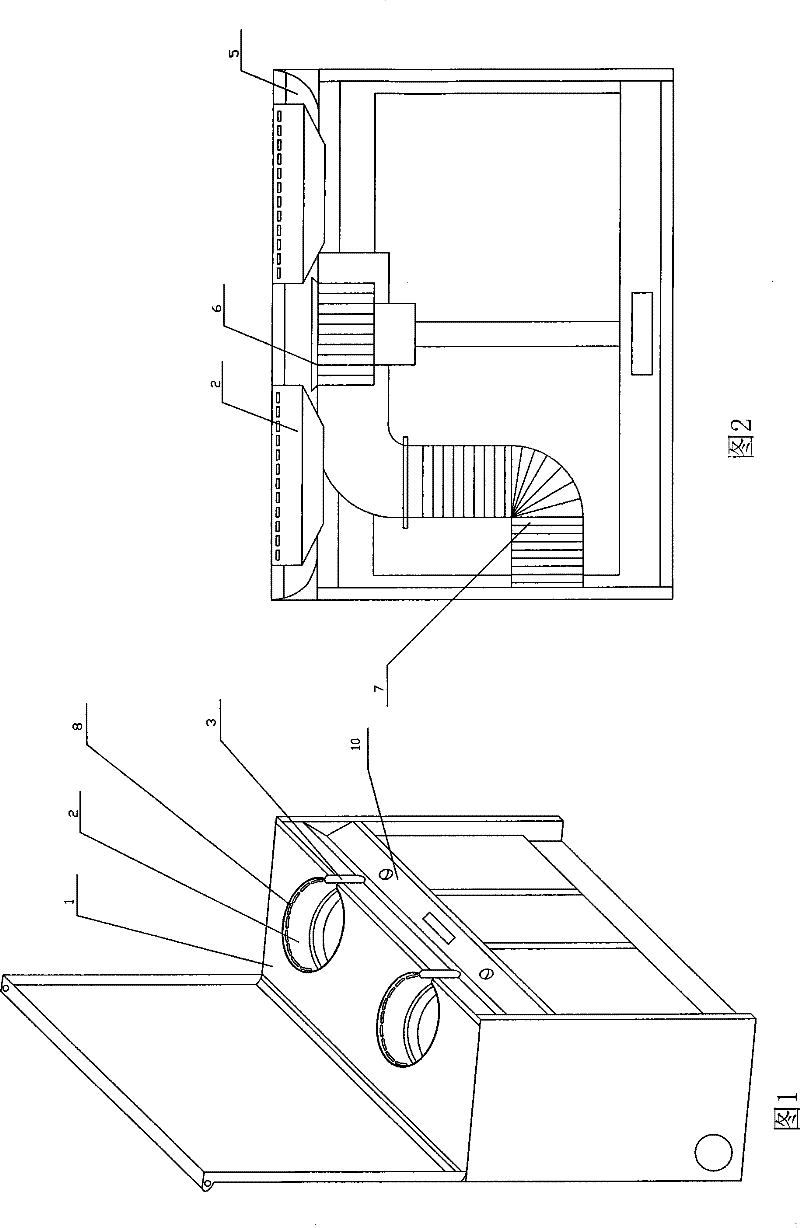

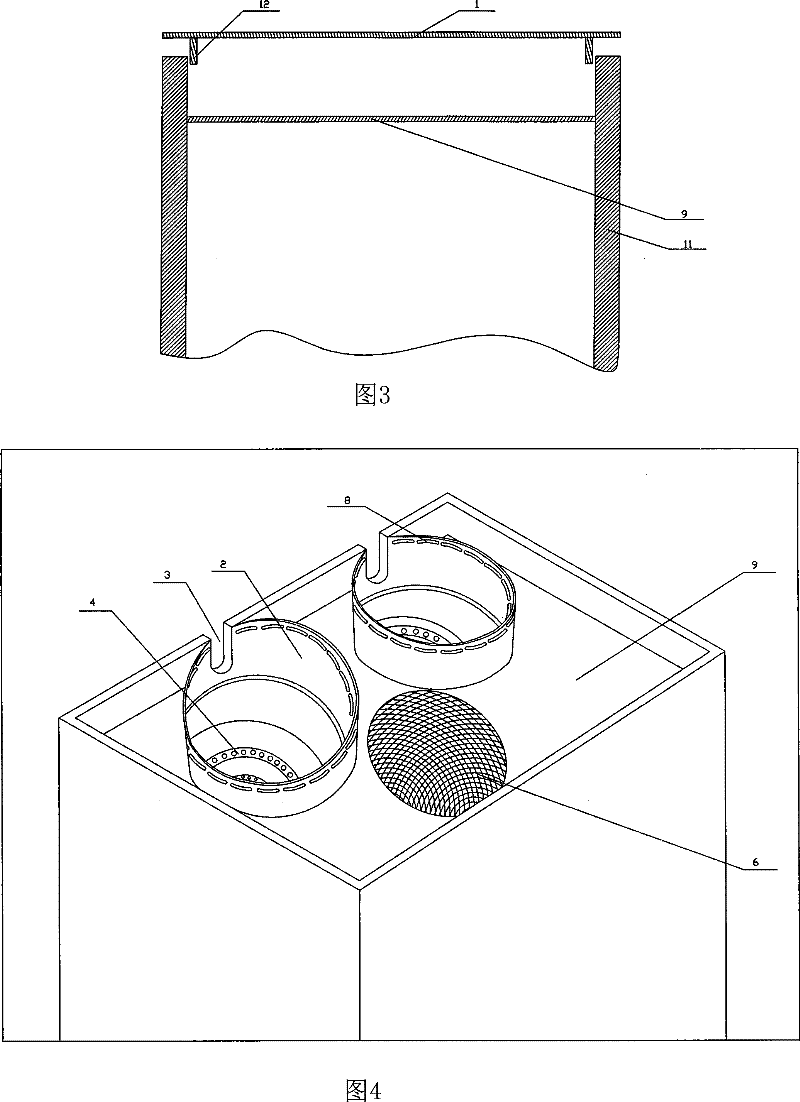

[0020] Reference attached Figure 1-7 :

[0021] The range hood and cooker integrated machine of the present invention includes a cabinet-type body, a concave cylindrical stove hole 2 is provided on the panel 1 of the fuselage, a stove 4 is provided on the bottom plate of the stove hole 2, and the wall of the stove hole The upper part is provided with a superior arc-shaped suction port 8, the stove hole 2 has a handle hole 3 on the side facing the person, the suction port 8 is covered in the air collecting box 5, and the air inlet of the fan 6 is arranged in the air collecting box In 5, the wall surface of the stove hole 2 is connected to the top and bottom plates of the air collecting box 5, the fan 6 is also connected to the exhaust pipe 7, and the cylindrical wall surface 13 of the stove hole 2 is buckled with the annular convex edge 14 on the bottom plate 9 Closely, the cylindrical wall surface 13 is wrapped around the convex edge 14.

[0022] Oil droplets may also condense on...

Embodiment 2

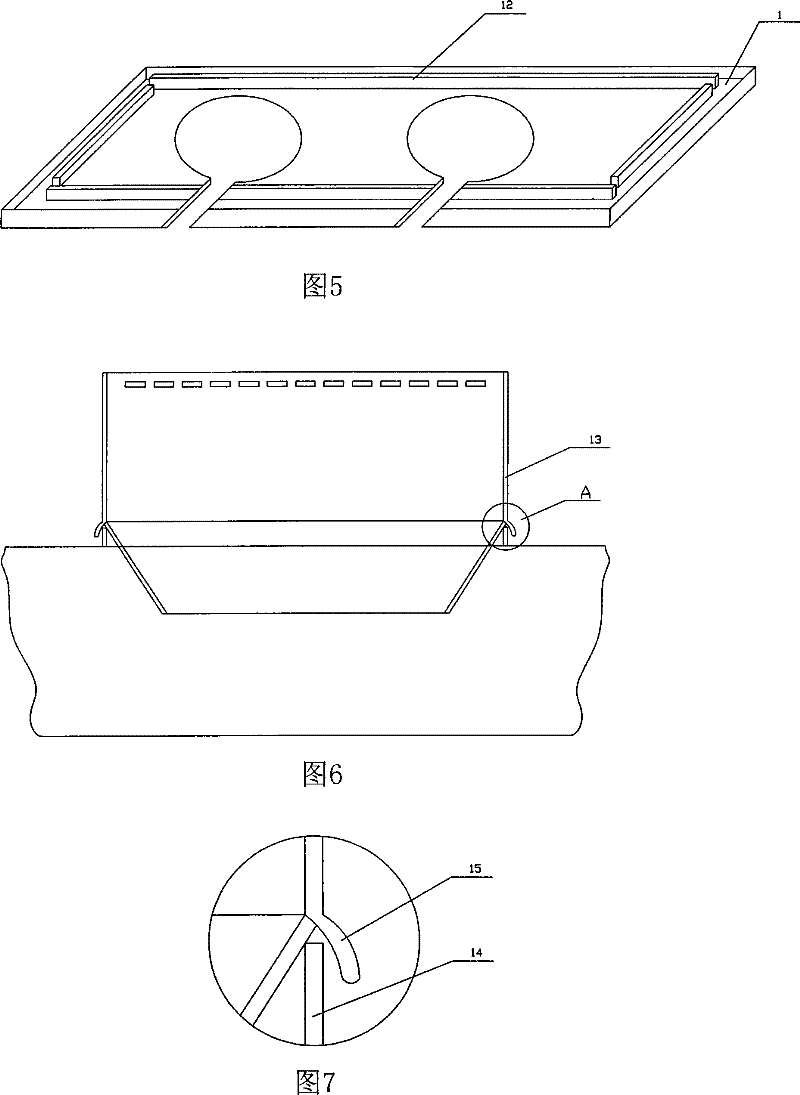

[0028] Reference attached Figure 1-5 :

[0029] The difference between this embodiment and the first embodiment is that: the back surface of the panel 1 is attached with a barrier strip 12 that covers the joining part of the panel 1 and the side wall 11.

[0030] The junction between the top panel and the bottom plate of the side wall is also easily penetrated by the condensed oil in the air collecting tank. After the oil droplets condense on the back of the panel, it will flow to the surroundings and then flow down the side wall. The existing countermeasures for the air collecting tank The main thing is to improve the welding accuracy. Although the cost has increased a lot, there is no obvious effect. Practice has proved that welding defects are inevitable. The present invention adds a barrier strip that shields the junction between the panel and the bottom plate on the reverse side of the panel. The oil droplets are guided down by the barrier strip before flowing to the junctio...

Embodiment 3

[0032] Reference attached Figure 1-7 :

[0033] The difference between this embodiment and the third embodiment is that the suction port on the stove hole is added: the upper part of the wall surface of the stove hole 2 is provided with a positive pressure suction port, and the suction port is opposite to the suction port. The air port is obliquely downward, and the air suction port is connected to a positive pressure air source through an air pipe.

[0034] The inhalation port is used in conjunction with the inhalation port, which is beneficial to form a fluid envelope surface above the oil fume generation source, and improves the oil fume absorption rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com