Anti-low voltage ride-through solution device and working method for powder feeder frequency converter in thermal power plant

A low-voltage ride-through and powder feeder technology, applied in electromechanical devices, motor control, electric brake/clutch, etc., can solve the problems of danger, poor low-voltage ride-through resistance of frequency converters, lack of availability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

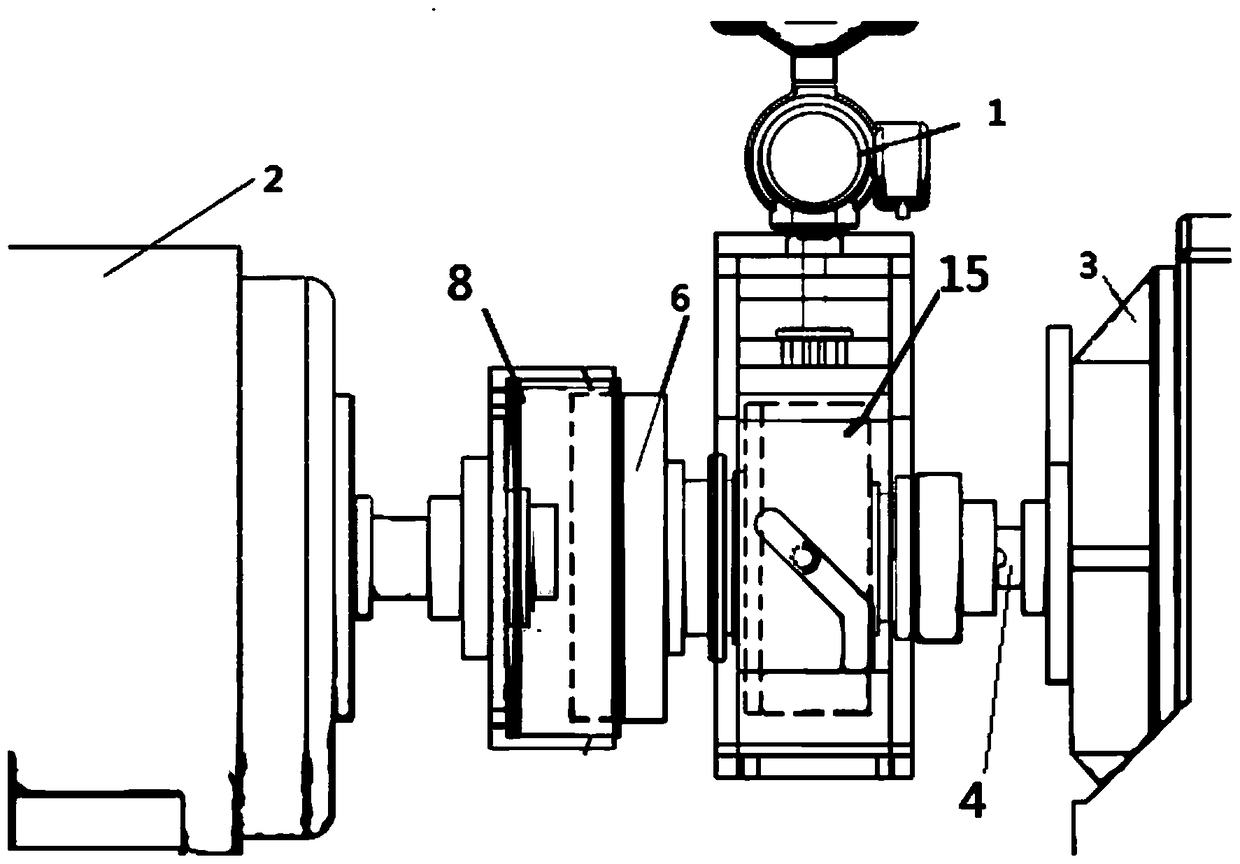

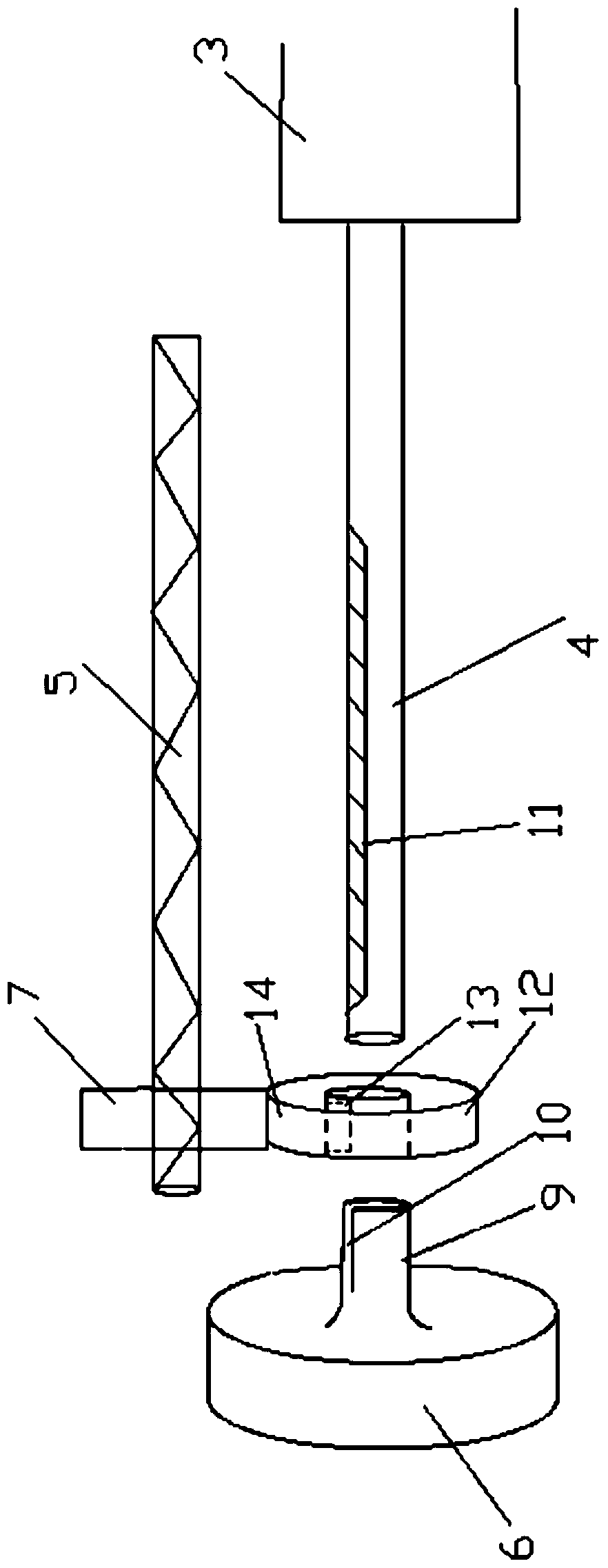

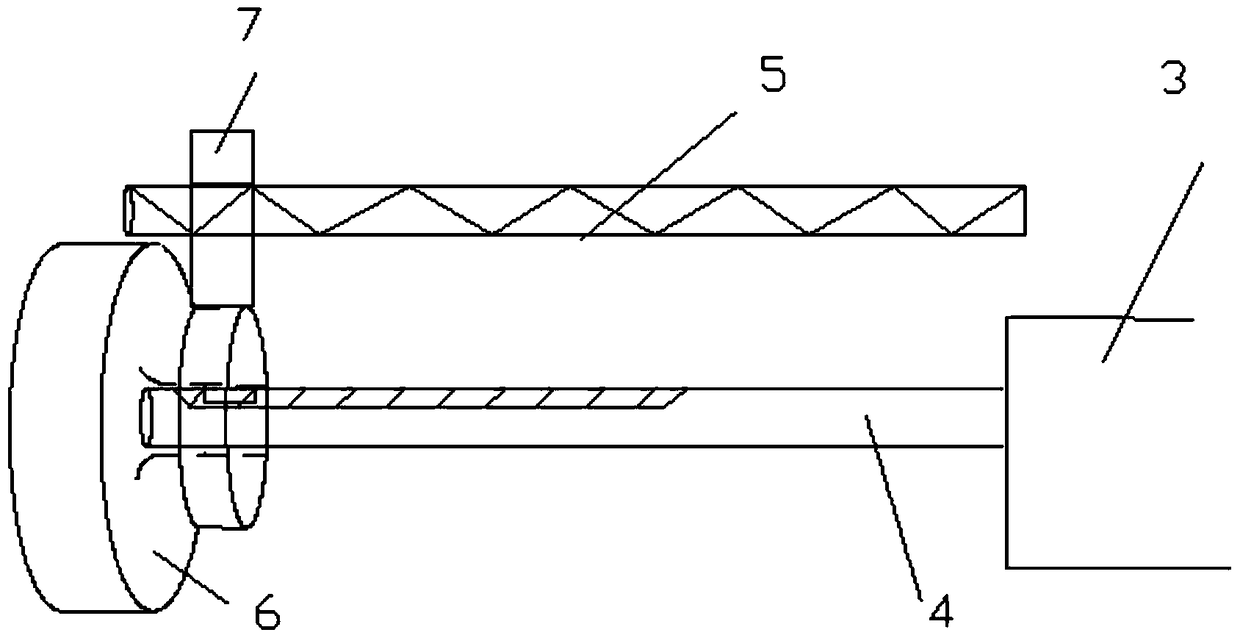

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] In the figure, the anti-low voltage ride-through solution device for the frequency converter of the powder feeder in the thermal power plant includes the DCS system of the power plant, the control device, the servo motor 1, the motor 2, the load 3, the transmission device, the transmission shaft 4, and the transmission shaft 4 is connected to the load 3. The DCS system of the power plant (not shown in the figure) is connected to the control device (not shown in the figure) for signal connection or electrical connection. Rotating speed carries out closed-loop adjustment control (closed-loop adjustment control is prior art), control device is electrically connected with servo motor 1 or signal is connected, and control device controls the forward and reverse stroke of servo motor 1, and servo motor 1 is connected with transmission device, preferably The transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com