Peristaltic pump having reduced pulsation and use of the peristaltic pump

A technology of peristaltic pumps and pulsation effects, applied to pumps with flexible working elements, pumps, pump components, etc., can solve problems such as high failure probability and pump wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

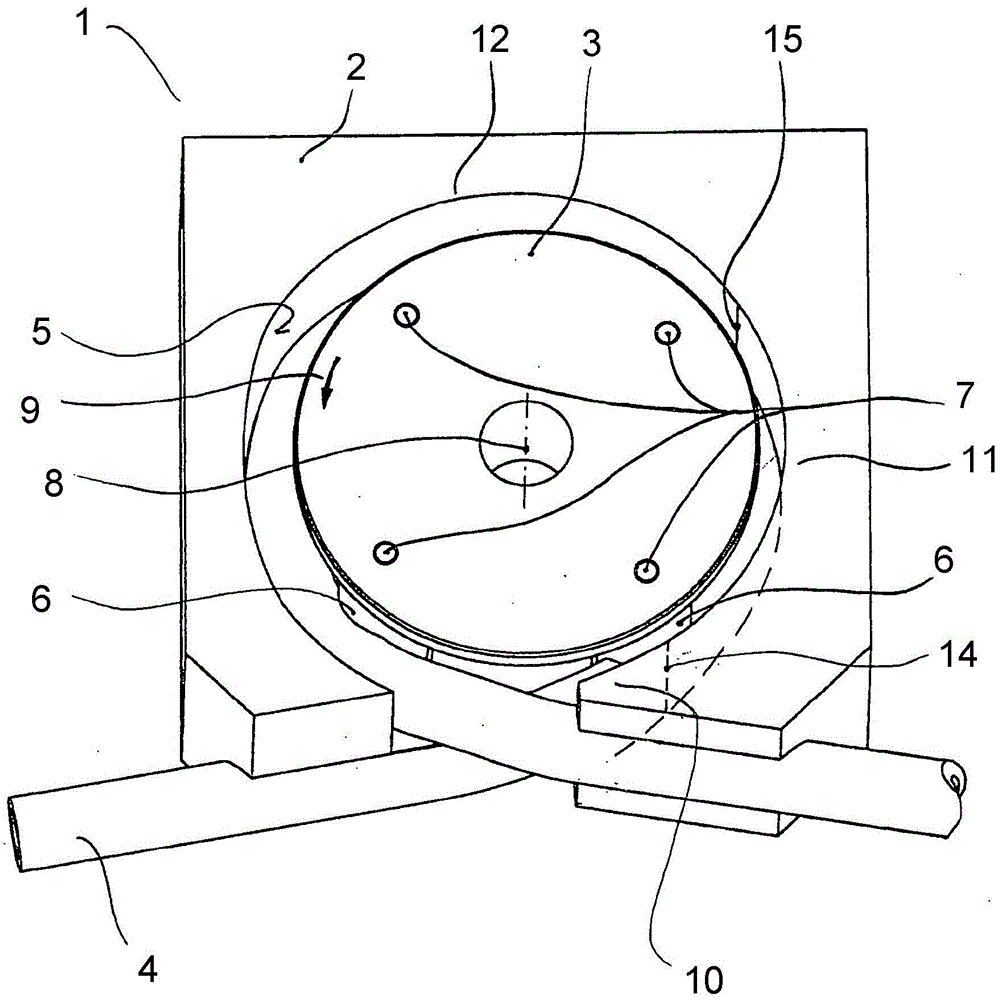

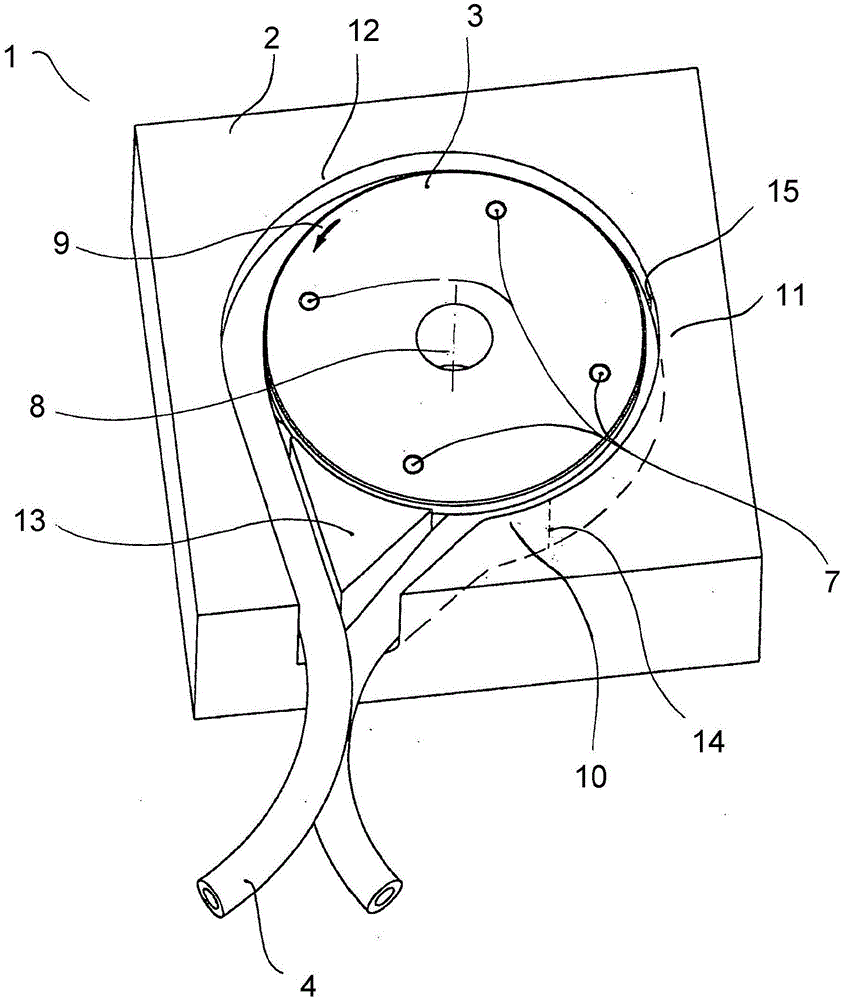

[0045] figure 1 A perspective view is shown of a peristaltic pump 1 comprising a saddle 2 inside which a rotor 3 is arranged. The hose 4 is arranged in the gap between the saddle inner surface 5 and the peripheral surface of the rotary part 3 . Arranged on the periphery of the rotary part 3 are four hose squeezing means 6 largely covered by the rotary part 3 . The hose squeezing means 6 are designed as rollers, which are each rotatable about the axis 7 of the rotor. The hose squeeze mechanism 6 engages in the hose 4 and compresses the hose so that it is at least temporarily closed by the hose squeeze mechanism 6 . The hose 4 is fixedly arranged in the saddle 2 . During the rotation of the rotor 3 , the hose squeezing mechanism 6 travels along the hose 4 and compresses it before the saddle inner face 5 . The illustrated peristaltic pump 1 has a winding angle of approximately 360°, the ends of the hoses 4 emerging from the peristaltic pump 1 crossing one another in or shortl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com