Slide rail locking mechanism

A locking mechanism and slide rail technology, applied in furniture parts, household utensils, drawers, etc., can solve the problems of reducing the service life of electromagnets and wasting energy, and achieve the effects of increasing stability, saving energy, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

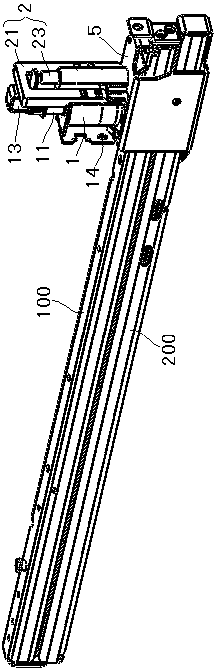

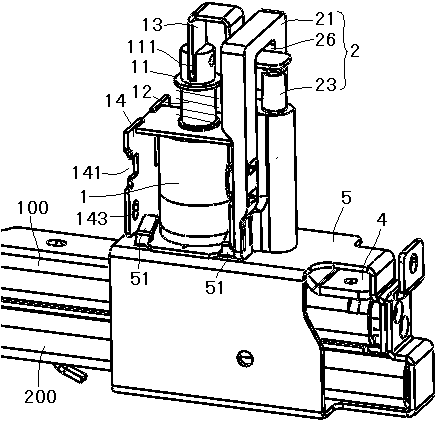

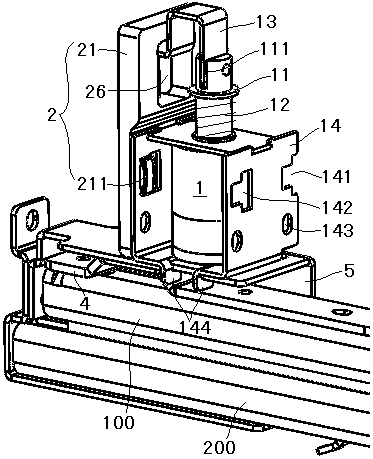

[0034] refer to figure 1 As shown, a sliding rail locking mechanism includes an electromagnet 1 arranged on one side of the inner rail 100, and the electromagnet 1 includes an iron core 11 and a first spring 12 connected to the iron core 11. The iron core 11 A pressing piece 13 is connected to the top, and the other end of the pressing piece 13 is arranged above the push self-locking mechanism 2 with intermittent locking function. Lock groove 41 is arranged. The inner rail 100 is connected with a lock slot frame 4 protruding from one side of the inner rail 100 , and the lock slot frame 4 is provided with the lock slot 41 . Pressing the intermittent locking function of the self-locking mechanism 2 enables the electromagnet 1 to be turned on once to realize locking, and to be turned on again to realize unlocking, which reduces the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com