Degassing equipment

An equipment and air channel technology, applied in the field of degassing equipment, can solve the problems of poor degassing effect and poor stirring effect of degassing equipment, and achieve the effects of improving stirring effect, preventing excessive pressure and improving degassing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

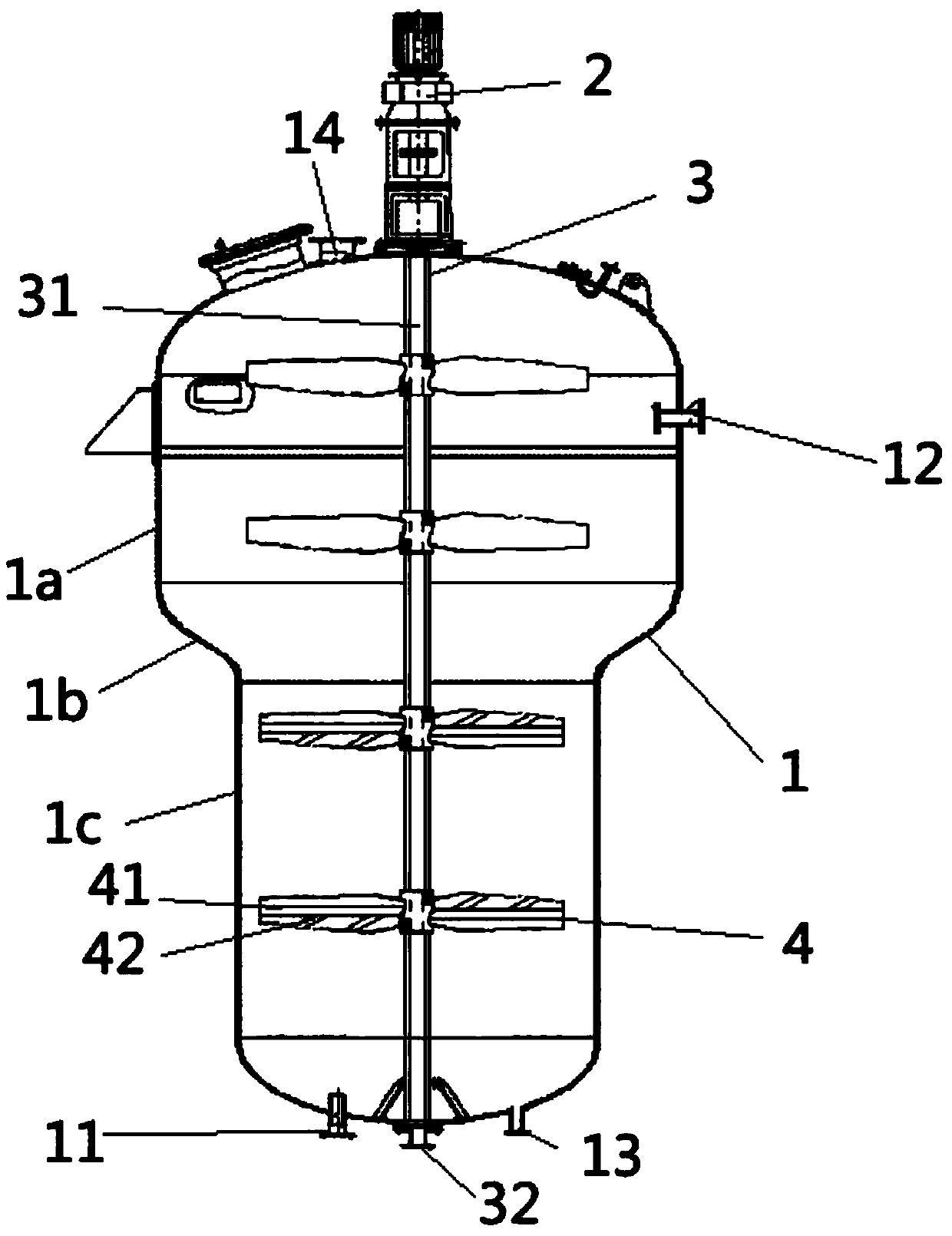

[0035] This embodiment provides a degassing device, such as figure 1 shown, including,

[0036] The kettle body 1 has an accommodation space, a feed port, an air extraction hole 14 at the top of the kettle and a discharge port 13 at the bottom;

[0037] Stirring device, including a rotating shaft 3 arranged vertically at the center of the kettle body 1 and driven by a power device to rotate, and several paddles 4 arranged on the rotating shaft 3;

[0038] The power device 2 is arranged outside the kettle body 1, and is connected to the rotating shaft 3 in transmission, and is used to drive the rotating shaft 3 to rotate;

[0039] A vacuum device communicated with the air extraction hole 14 for extracting the gas in the kettle body 1;

[0040] The rotating shaft 21 is hollow to form an air passage 31, and the paddle 4 is formed with a number of air jets communicating with the air passage 31;

[0041] One end of the air passage 31 communicates with the steam supply pipe, so t...

Embodiment 2

[0061] The present embodiment provides a kind of degassing method of carboxylated styrene-butadiene latex, using the degassing equipment of embodiment 1, the temperature of the described steam that is passed into air channel 31 is 150 ℃, and the steam addition is 20kg / h (by kettle per ton of carboxylated styrene-butadiene latex emulsion in the body 1), the rotational speed of the rotating shaft 21 is 8 revolutions per minute, and the pressure of -0.09MPa is kept in the kettle body 1 by a vacuum device, and the temperature is kept at 60 ℃, the steam feeding time is 1.5h, after which the steam feeding is stopped, and 2Nm 3 The nitrogen of / h (calculated with every ton of carboxylated styrene-butadiene latex emulsion in the kettle body 1) passes into the time for half an hour, and when the temperature in the kettle body 1 is lower than 50° C., the carboxylated styrene-butadiene latex is discharged.

Embodiment 3

[0063] The present embodiment provides a kind of degassing method of carboxylated styrene-butadiene latex, using the degassing equipment of embodiment 1, the temperature of the described steam that is passed into airway 31 is 160 ℃, and the steam addition is 22kg / h (by kettle per ton of carboxylated styrene-butadiene latex emulsion in the body 1), the rotational speed of the rotating shaft 21 is 11 revolutions per minute, and the pressure of -0.09MPa is kept in the kettle body 1 by a vacuum device, and the temperature is kept at 65 ℃, the steam feeding time is 1.8h, after which the steam feeding is stopped, and 3Nm 3 The nitrogen of / h (calculated with every ton of carboxylated styrene-butadiene latex emulsion in the still body 1), feed time 50 minutes, and when the temperature in the still body 1 was lower than 50 ℃, carboxylated styrene-butadiene latex was discharged.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap