Pneumatic vehicle body punching device

A pneumatic punching and automobile body technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of poor application effect, difficult transformation, complex structure, etc., and achieve low cost, low manufacturing cost, and device The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

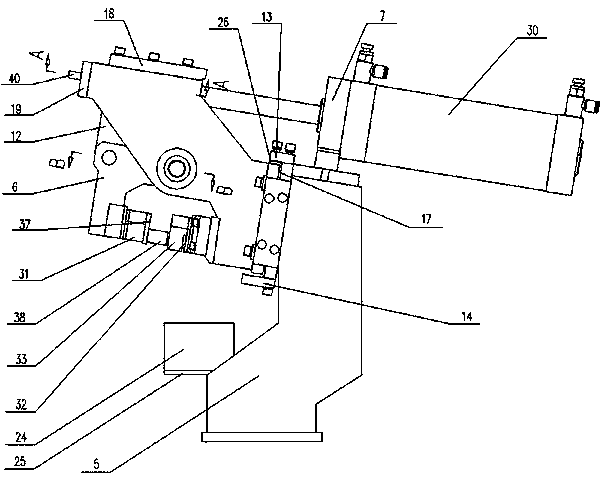

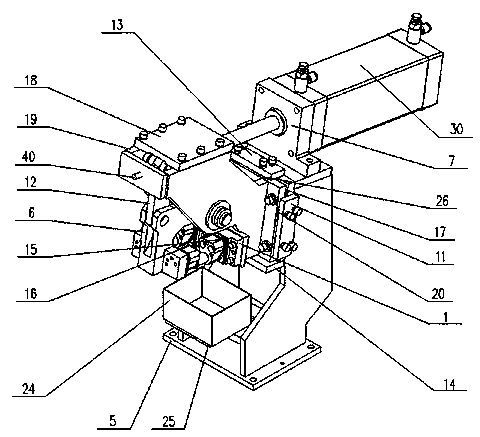

[0022] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

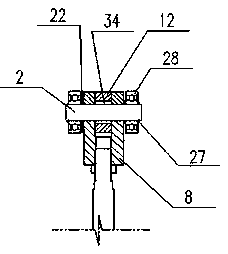

[0023] Such as Figure 1-Figure 4 As shown, a pneumatic punching device for a car body, the device includes a base 5, and one end of the upper part of the base 5 is provided with a bracket 7, and the bracket 7 is provided with a driving cylinder 30 that provides a power source for punching operation; A cylinder head 8 is provided, and the cylinder head 8 and the driving connecting plate 12 are hinged through the pin one 2, the driving connecting plate 12 and the turning arm 6 are hinged through the pin three 4, and the turning arm 6 and the base 19 are hinged through the pin two 3, That is, the driving cylinder 30, the driving connecting plate 12, and the overturning arm 6 form a four-bar linkage structure.

[0024] The cylinder head 8 is installed together with the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com