Side core-pulling mechanism for dog-leg cam of compression mould

A lateral core-pulling and die-pulling technology is applied in the field of the lateral core-pulling mechanism of a compression die bending pin, which can solve the problems of manpower consumption and low production efficiency, and achieve the effects of saving time, improving production efficiency and saving human resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

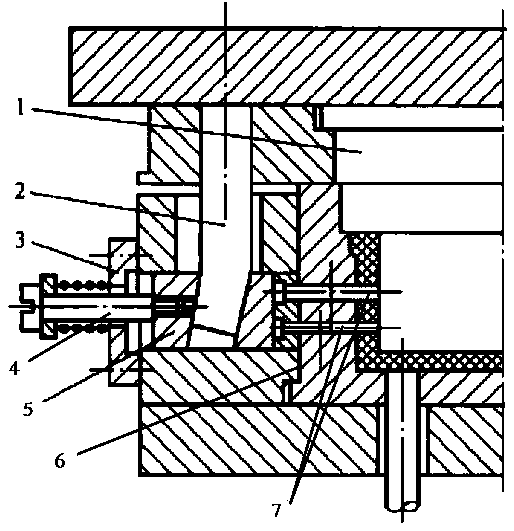

[0016] The reference signs in the accompanying drawings of the description include: punch 1, bent pin 2, cover plate 3, pressure rod 4, slider 5, die 6, movable lateral core 7.

[0017] Embodiment The clamping state of the bending pin 2 lateral core-pulling mechanism of the compression mold is basically as attached figure 1 Shown:

[0018] The side wall of the die 6 is provided with a slider groove for accommodating the slider 5, which is fixedly connected with the bent pin 2 on the punch 1 and passes through the through hole on the wall of the die 6, and its outwardly warped end stretches into the slide. In the oblique hole slidingly matched with it on the block 5; a cover plate 3 is fixed outside the opening of the slider groove on the left side of the slider 4, and a through hole is opened on the cover plate 3, and the pressure rod 4 is arranged horizontally and passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com