an air seal

An air-tight body and air chamber technology, which is applied in the direction of containers, containers, transportation and packaging to prevent mechanical damage, and can solve the problems of difficult insertion and easy adhesion of air gun air nozzles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

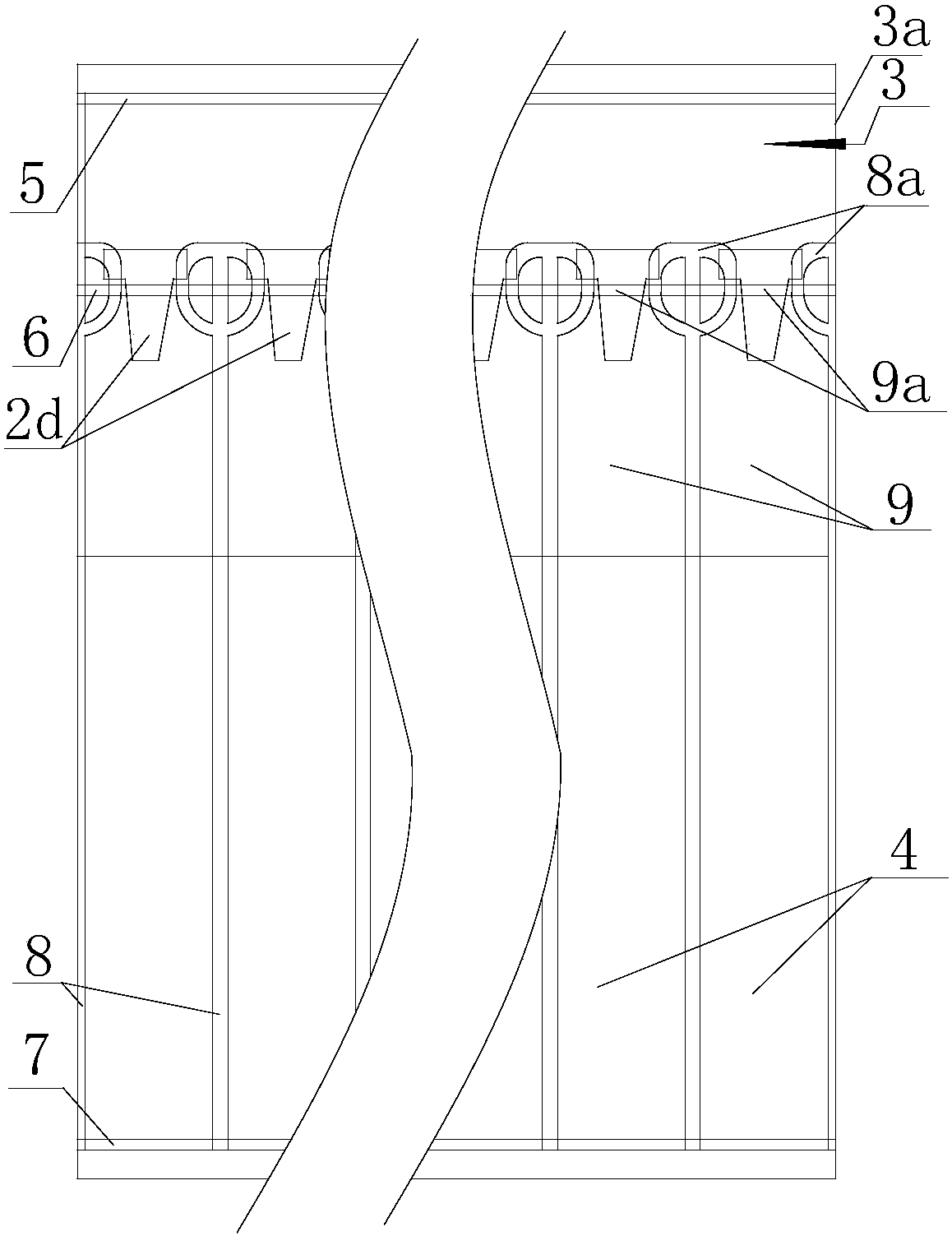

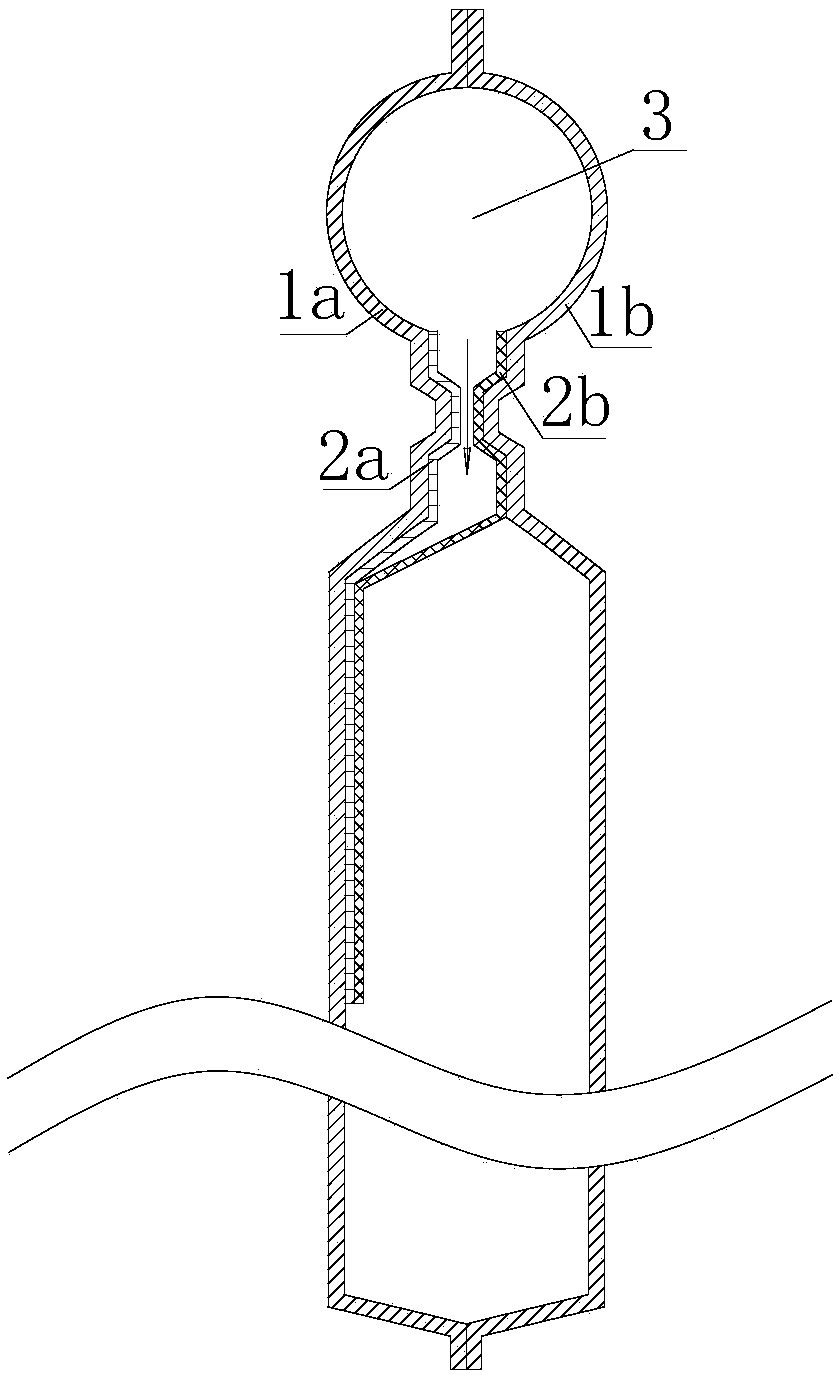

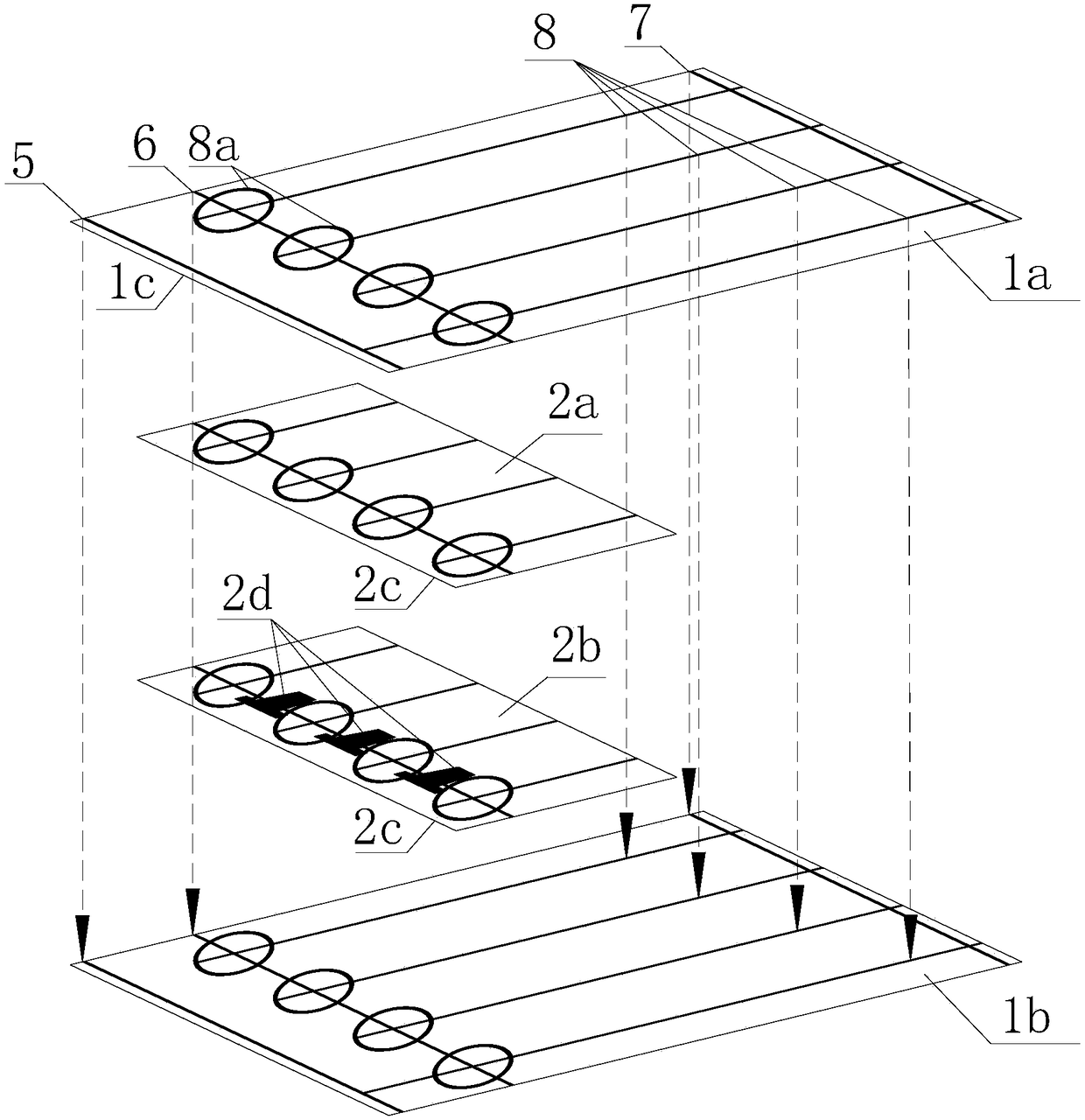

[0023] Such as Figure 1 to Figure 3 , the air-tight body in this embodiment, including the front outer membrane 1a, the rear outer membrane 1b, the front inner membrane 2a, the rear inner membrane 2b, the inflation channel 3, a plurality of air chambers 4, the top heat-sealing line 5, and the middle heat-sealing Line 6, bottom heat seal line 7, longitudinal heat seal line 8 and air intake channel 9.

[0024] The anterior adventitia 1a and the posterior adventitia 1b overlap up and down.

[0025] The anterior intima 2a and the posterior intima 2b are superimposed and located between the anterior adventitia 1a and the posterior adventitia 1b, and the top edge line 2c of the anterior and posterior intima is lower than the top edge line 1c of the anterior and posterior adventitia . In this embodiment, the size of the anterior and posterior adventitia is the same, the size of the anterior and posterior intima is also the same, and the width of the intima is the same as that of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com