a live bottom silo

A silo and movable bottom technology, applied in the field of feeding equipment, can solve the problems of increased manufacturing cost and difficulty, and achieve the effects of low equipment cost, improved volume ratio, easy operation and realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

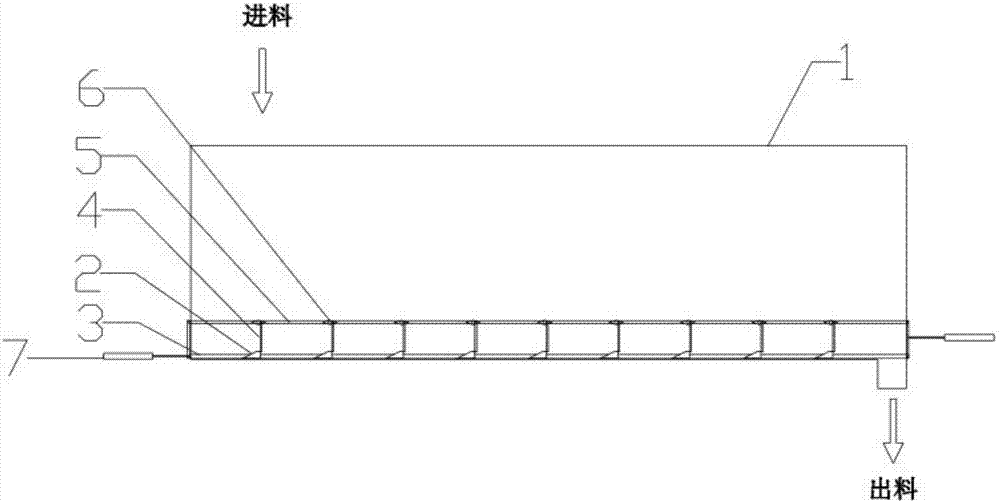

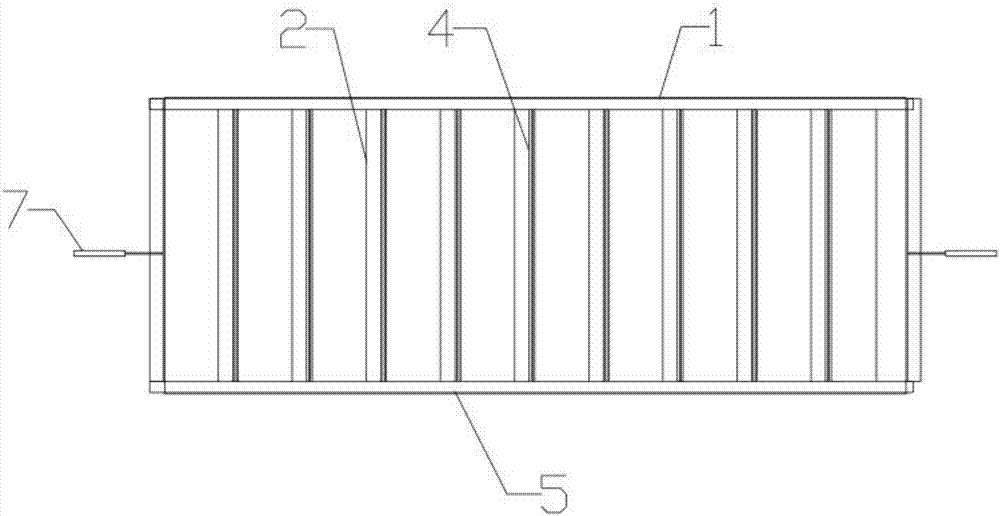

[0013] A live-bottom silo, comprising a silo body 1, the upper left side of the silo body 1 is provided with a material inlet, the lower right side is provided with a material outlet, and the bottom of the silo body 1 is provided with several outlets. The evenly distributed wedge-shaped push plates 2 perpendicular to the material direction, the push plates 2 are connected to each other through the first connecting rod 3, the end of the first connecting rod 3 is connected with the oil cylinder 7, and the apex of the wedge-shaped push plate 2 Rotationally connected with a turning plate 4, the bin body 1 is provided with a second connecting rod 5 parallel to the first connecting rod 3, the height of the second connecting rod 5 matches the height of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com