Novel multi-spindle sequin machine

A sequin, a new technology, applied in the decoration of textiles, textiles and papermaking, yarn, etc., can solve the problems of being unable to meet unlimited fashion needs, high-end clothing fabrics, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

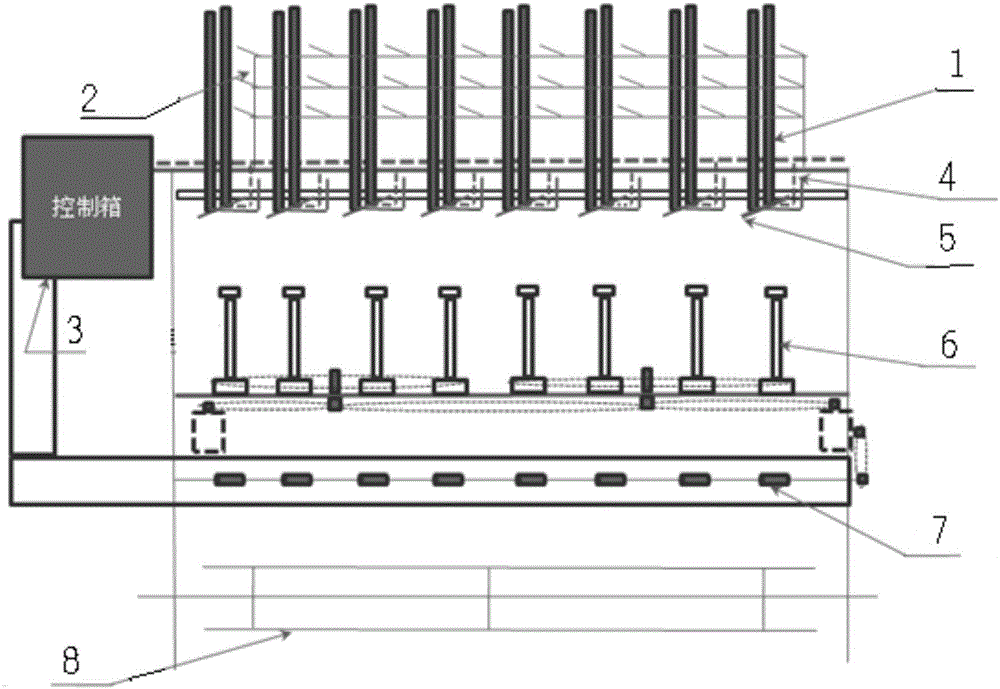

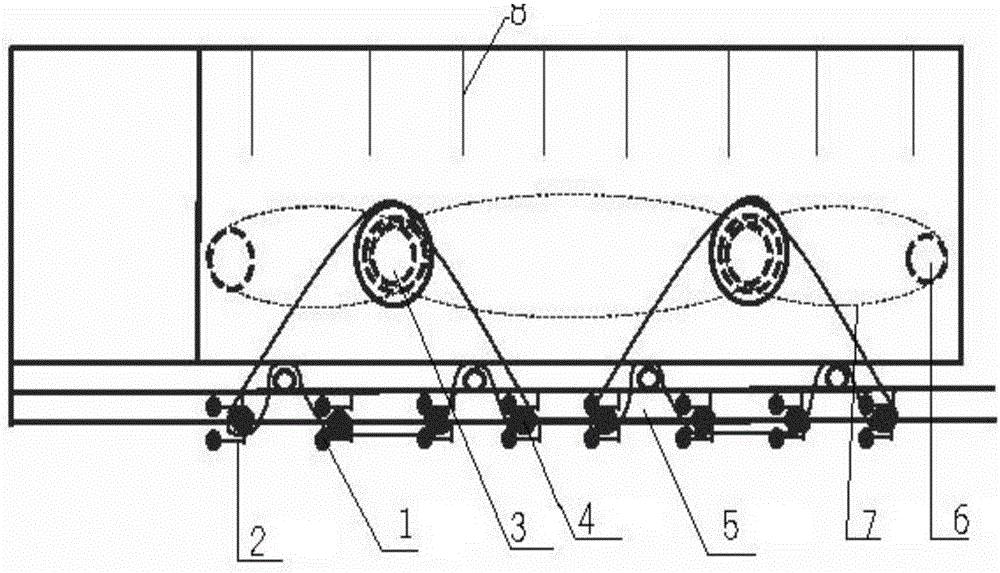

[0022] combine figure 1 and figure 2 , a new type of multi-spindle bead chip machine is characterized in that it includes a plexiglass tube 1, a yarn hanger 2, an electromagnet pusher 3, a bead pusher 4, a double-slot pusher platform 5, and a twisting spindle 6. Twist control transmission mechanism 7 and sand collection frame 8, wherein there are eight groups of plexiglass tubes 1 and are located at the front end of the machine, and the yarn hanging frame 2 is in front of the plexiglass tube 1 and connected with each group of plexiglass tubes 1 overlap, the electromagnet pusher 3 is located below the machine and provides power for the entire machine, the bead pusher 4 is located directly below the plexiglass tube 1 and is connected to the electromagnet pusher 3, and the double-slot pusher platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com