Non-drainage load test device and method of fixed side confinement socketed piles

A load test and rock-socketed pile technology, which is applied in the test of foundation structure, construction, foundation structure engineering, etc., can solve problems such as failure to consider the influence of pile end bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

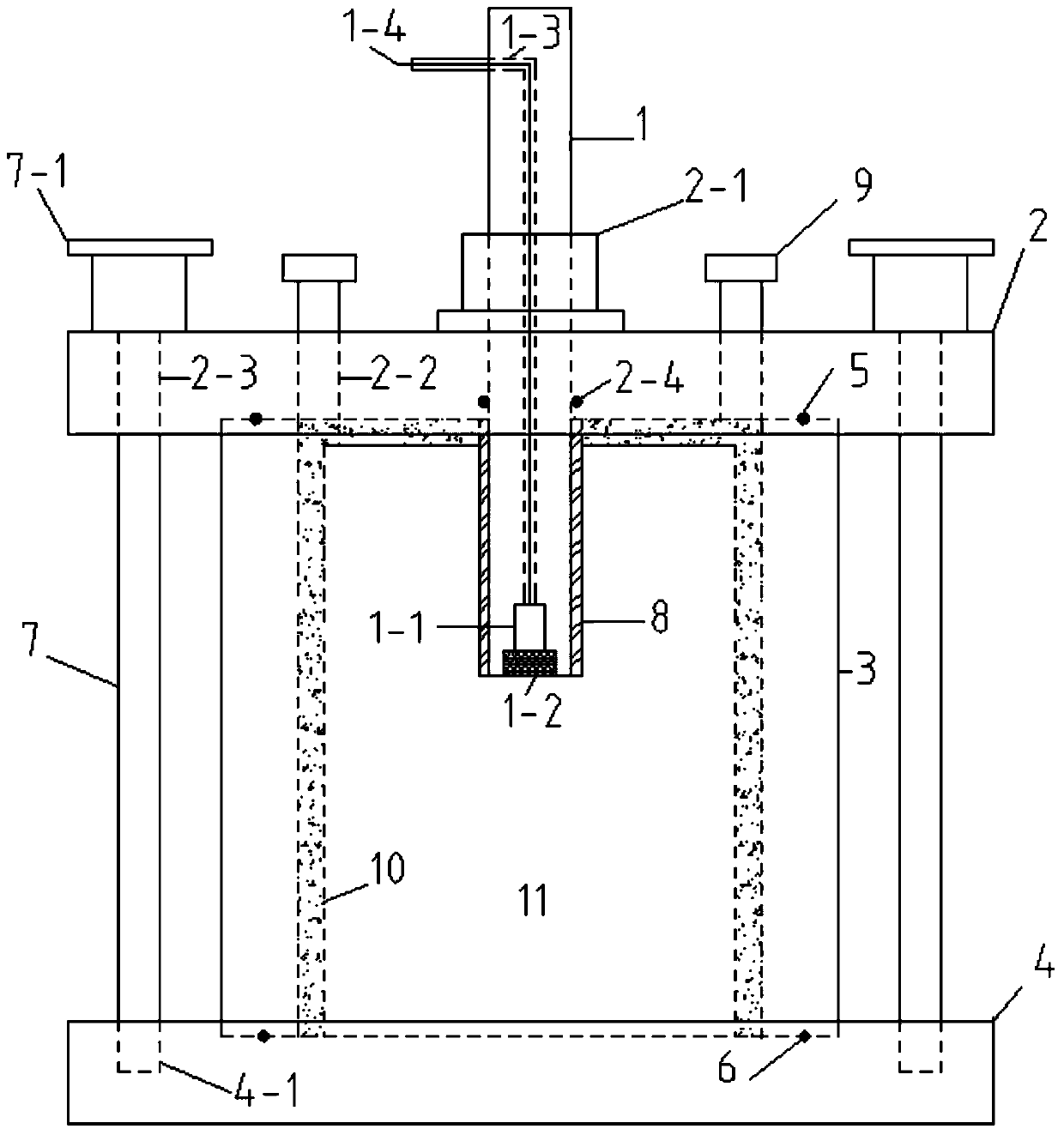

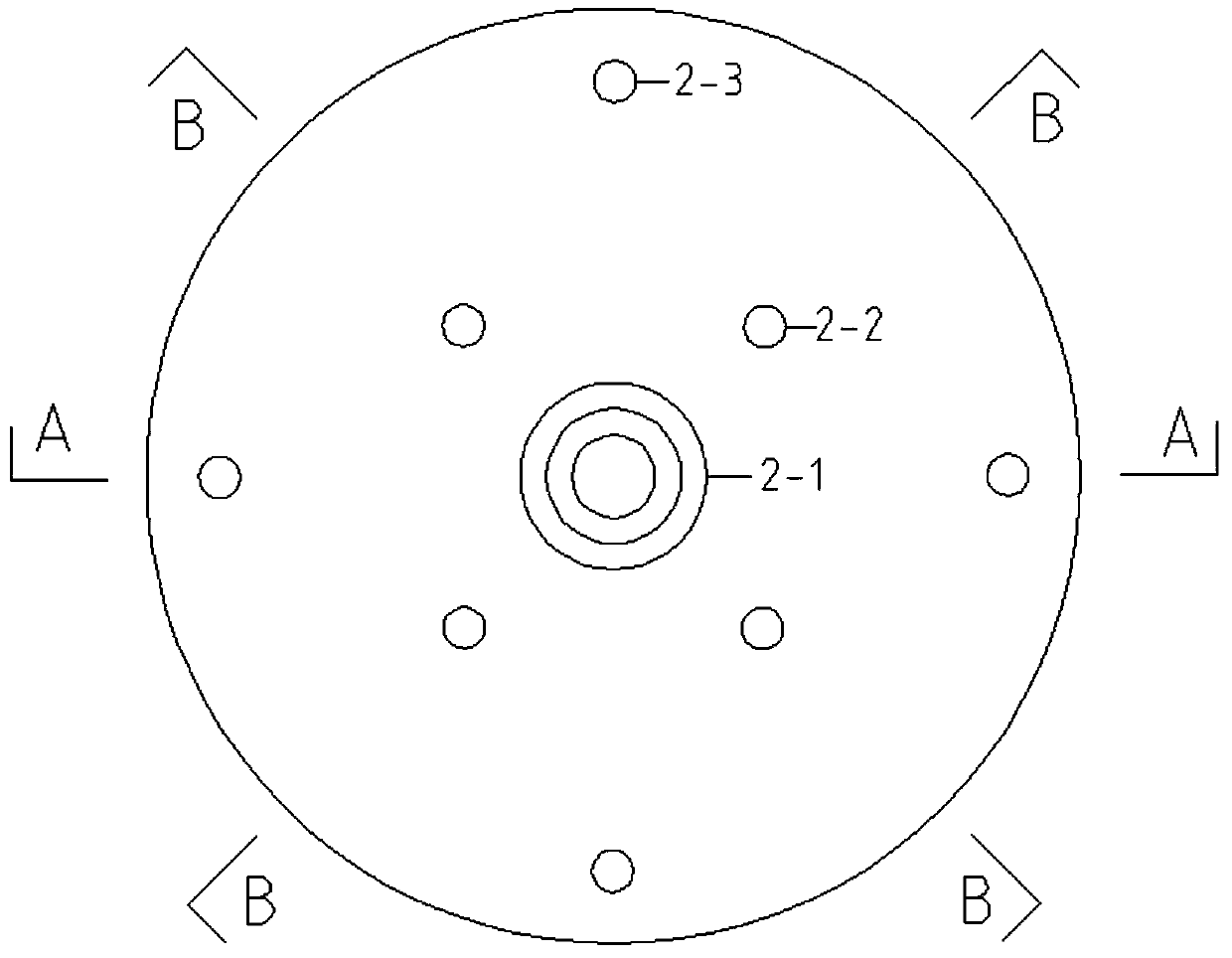

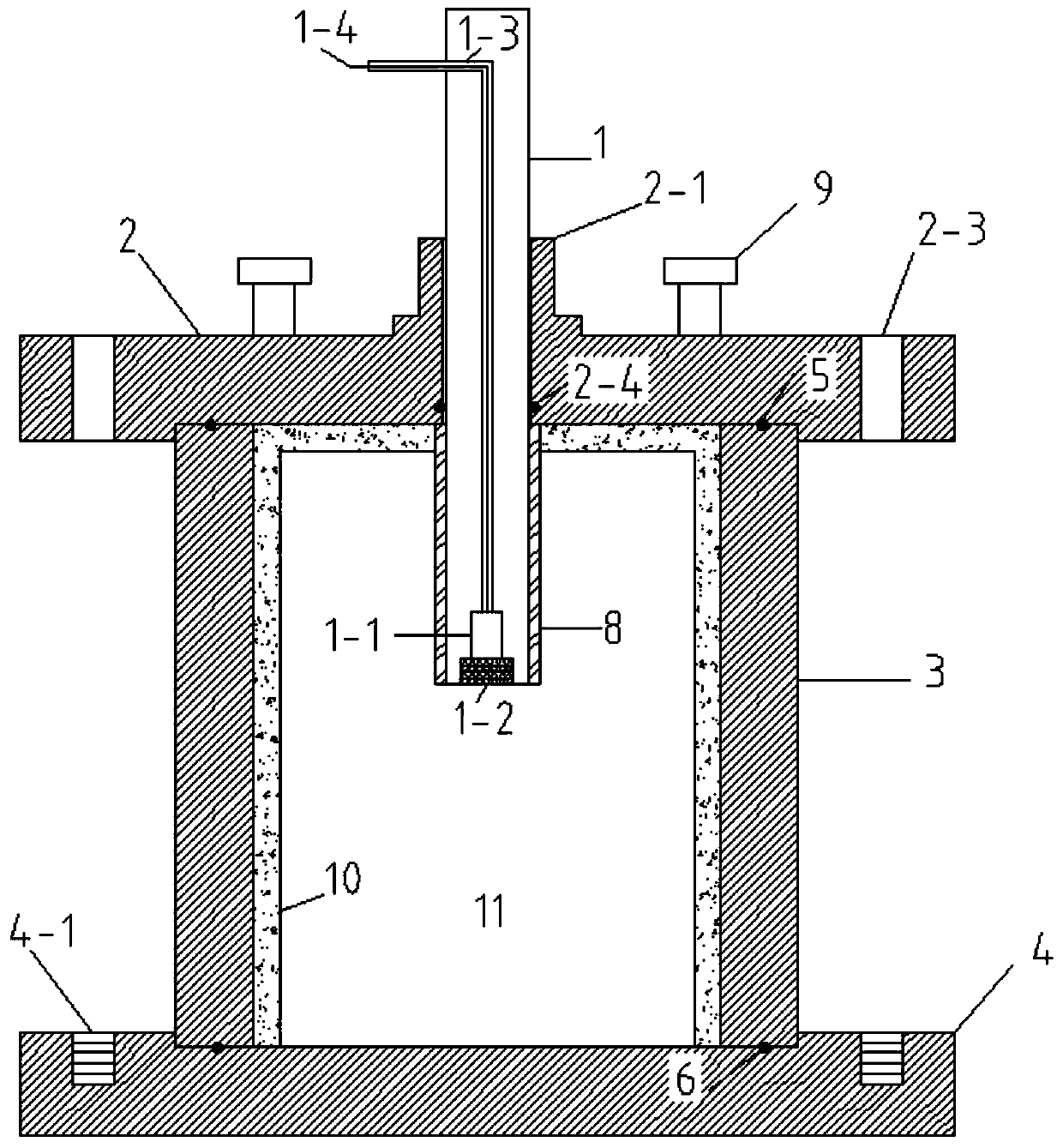

[0064] The following describes the device in detail with reference to the drawings and embodiments:

[0065] 1. Overall

[0066] Such as figure 1 , 2 , 3, 4, this device includes model pile 1, upper cover 2, pressure chamber 3, lower cover 4, upper sealing ring 5, lower sealing ring 6, screw 7, PVC-U tube 8, sealing nut 9, Cement slurry 10 and rock sample 11;

[0067] The pore pressure sensor 1-1 is embedded in the bottom of the model pile 1, and the copper filter plug 1-2 is set at the bottom of the pore pressure sensor 1-1. The lead 1-4 of the pore pressure sensor 1-1 is from the inner hole 1-3. Lead in

[0068] The upper cover plate 2 is provided with a central guide pipe 2-1, a grouting exhaust hole 2-2, a perforation 2-3 and a sealing ring 2-4;

[0069] A threaded hole 4-1 is provided on the lower cover plate 4;

[0070] Its location and connection relationship are:

[0071] From bottom to top, the lower cover 4, the pressure chamber 3 and the upper cover 2 are connected in sequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com