Heat-insulation house for concrete curing in winter concrete construction

A heat preservation shed and concrete technology, which is applied in construction, building structure, construction material processing and other directions, can solve the problems of inability to guarantee the maintenance strength of concrete, poor light transmission of ordinary straw curtains, and unfavorable on-site civilized construction, etc., and is easy to expand. Promote the use, help to improve the strength, and have a significant application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

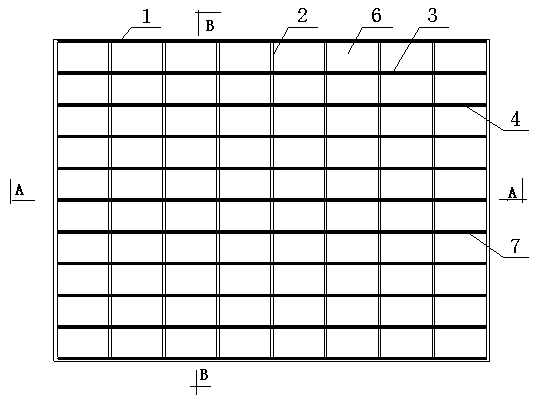

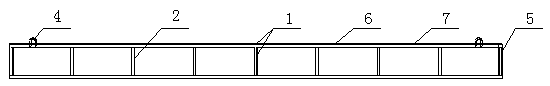

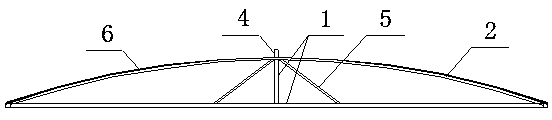

[0019] see Figure 1-Figure 4 , a winter construction concrete maintenance heat preservation shed, the heat preservation shed consists of: frame 1, lateral support 2, longitudinal support 3, suspension nose 4, bracket 5, insulation layer 6 and positioning strip 7; the heat preservation shed is surrounded by frame 1 , wherein the horizontal support 2 and the longitudinal support 3 are respectively arranged at intervals, the two ends of the longitudinal support are provided with hanging noses 4, the longitudinal support 3 is arranged in the middle position of the insulation shed; the bracket 5 is arranged at the middle of the middle longitudinal support 3 On both sides; the insulation shed frame is covered with an insulation layer 6 as a whole.

[0020] For example, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com