A device and method for enhancing gas drainage integrated with cutting, sealing and pressure

A technology of gas drainage and slotting, which is applied in the direction of gas discharge, safety devices, mining fluids, etc., can solve the problems of lax sealing of high-pressure boreholes and poor gas drainage effects, etc., and achieves wide practicability and workload Small, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

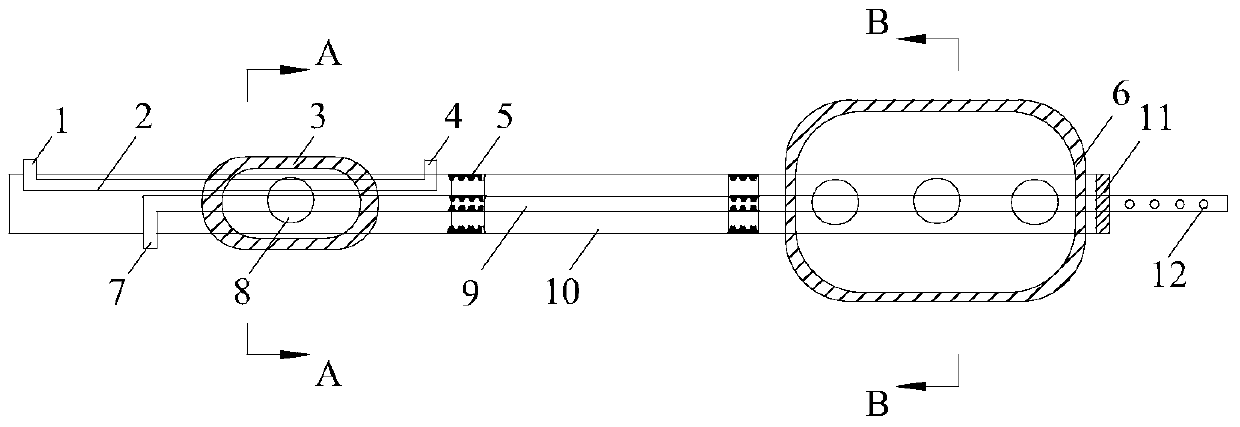

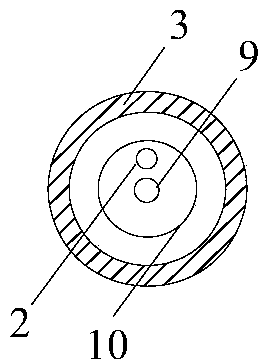

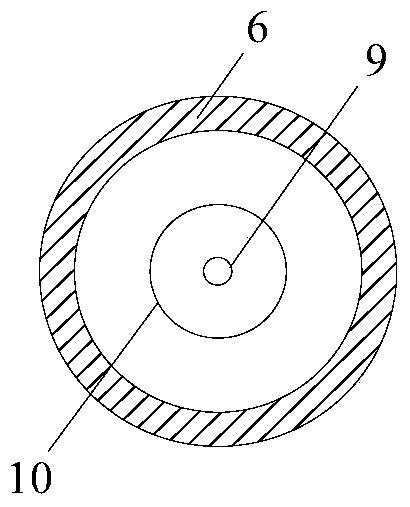

[0026] figure 1 As shown, the present invention is an integrated cutting, sealing and pressure enhanced gas drainage device, which includes a grouting cylinder 10 interconnected by threads 5, and a fracturing pipe 9 with a number of small holes 12 at the front end arranged at the center of the cylinder 10. , the fracturing tube 9 passes through the front end of the cylinder front cover 11 for 3-4m, so that all the small holes 12 go over the cylinder 10, and the rear end of the fracturing tube 9 is connected to the fracturing pump through the fracturing port 7 on the lower surface of the cylinder 10, The fracturing port 7 is 0.5-1m away from the rear end surface of the cylinder 10. The front end of the cylinder 10 is welded with a flexible bladder 1 6, and a flexible bladder 2 3 is welded at a position 1.5-3m away from the rear end surface of the cylinder 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com