Dynamic pressure lubricating method and structure

A lubricating structure and lubricant technology, applied in the direction of gear lubrication/cooling, transmission parts, belts/chains/gears, etc., can solve the problem of affecting the transmission accuracy and transmission efficiency of the push rod mechanism, cannot produce convergent fluid wedges, and cannot form Wedge-shaped lubricating film and other problems, to achieve the effect of improving transmission accuracy and transmission efficiency, stable position, and increased working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

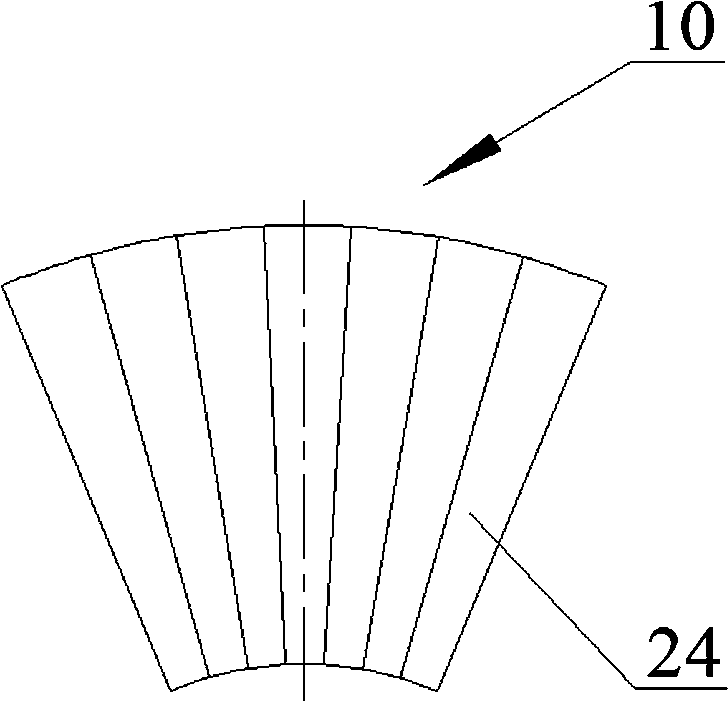

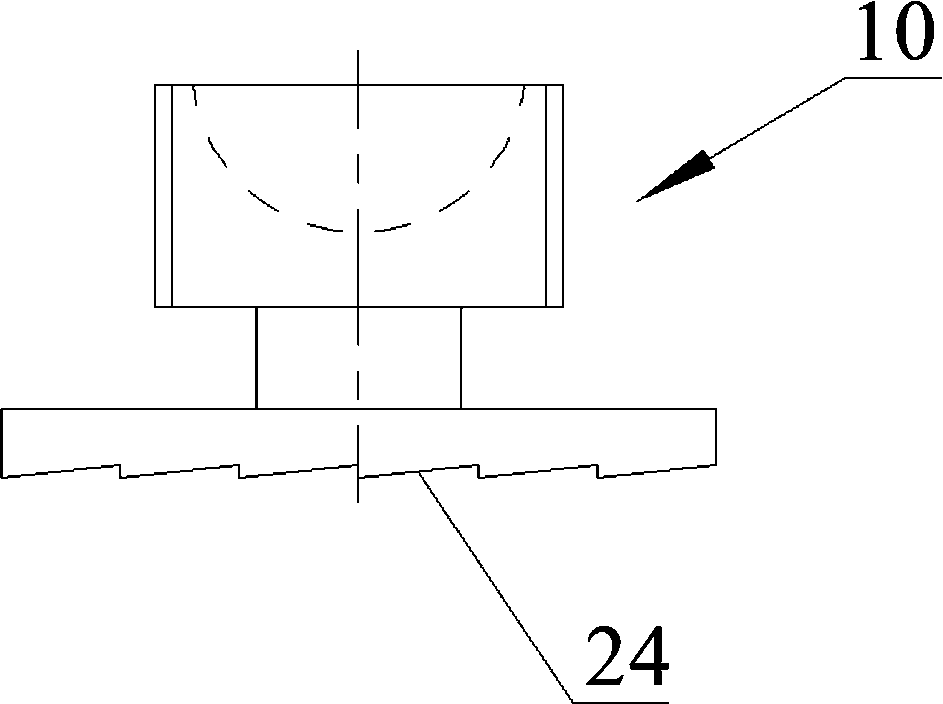

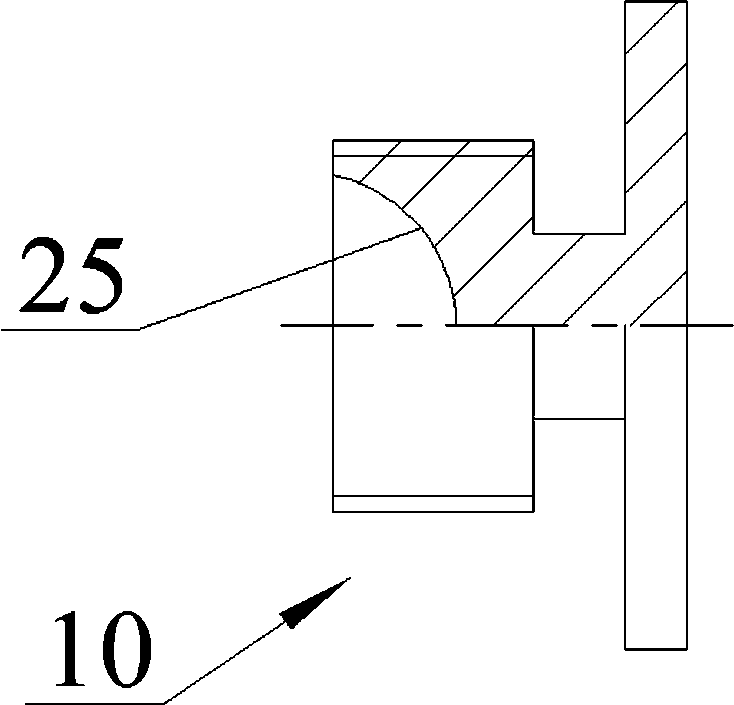

[0066] One aspect of the present invention provides a method of dynamic pressure lubrication. The structure for implementing the method includes a dynamic pressure lubrication shoe 10 and a relative movement plane. A plurality of slopes 24 are radially provided on the bottom surface of the bottom surface, and a convergent fluid wedge is formed between the plurality of slopes 24 and the relative motion plane, and a lubricant is provided in the convergent fluid wedge, including the following steps:

[0067] Step a. On the premise that the lubricant has sufficient viscosity, a wedge-shaped lubricating film can be generated between the several inclined surfaces 24 and the relative motion plane, so as to form sufficient bearing pressure to bear the external load;

[0068] Step b. When the speed of the relative movement between the several inclined surfaces 24 and the relative motion plane reaches a certain size, the lubricant between the two relatively moving friction surfaces will ...

Embodiment 2

[0072] A method and structure of dynamic pressure lubrication, which is similar to Embodiment 1, except that: the liquid lubricant uses synthetic lubricating oil.

Embodiment 3

[0074] A dynamic pressure lubrication method and structure, which are similar to Embodiment 1, except that: the fluid lubricant is a gas lubricant, and the gas lubricant is air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com