Power line clamp detection method

A technology of a power line clip and a detection method, applied in the field of detection, can solve problems such as loss of economic effects, occurrence of accidents, simplicity, etc., and achieve the effects of avoiding economic losses, improving detection accuracy, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

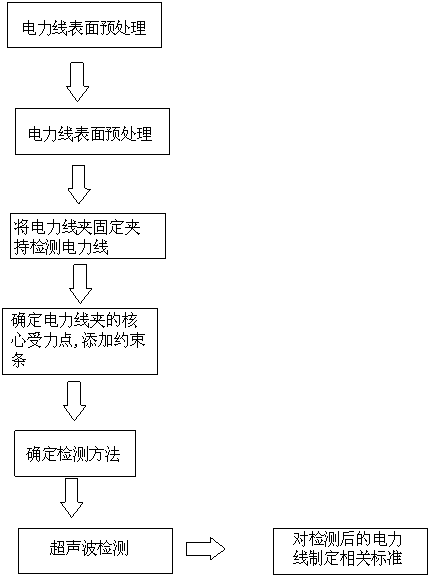

[0025] Attached below figure 1 The present invention is described further:

[0026] Such as figure 1 As shown, a) power line surface pretreatment: remove the oil and dirt on the surface of the detected power line after polishing, then wash with deionized water and finally dry;

[0027] (b) Fix and clamp the detected power line with the power line clamp, simulate the force on the in-service power line clamp, and establish the force model of the above-mentioned detected power line;

[0028] (c) Determine the core stress points of the above-mentioned power line clamps, and add constraints;

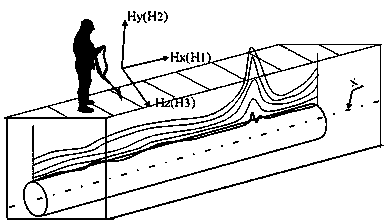

[0029] (d) Determine the detection method: detect the parameters such as the outer diameter of the detected power line, the groove diameter, and the wall thickness difference through electromagnetic waves;

[0030] (e) Ultrasonic testing: testing the material of the detected power line material and the depth of defect cracks by ultrasonic testing;

[0031] (f) Establish the relevant stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com