Cleaning cycle determining method of solar photovoltaic assembly

A solar photovoltaic, cleaning cycle technology, applied in the field of solar energy, to achieve the effect of improving resource waste and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

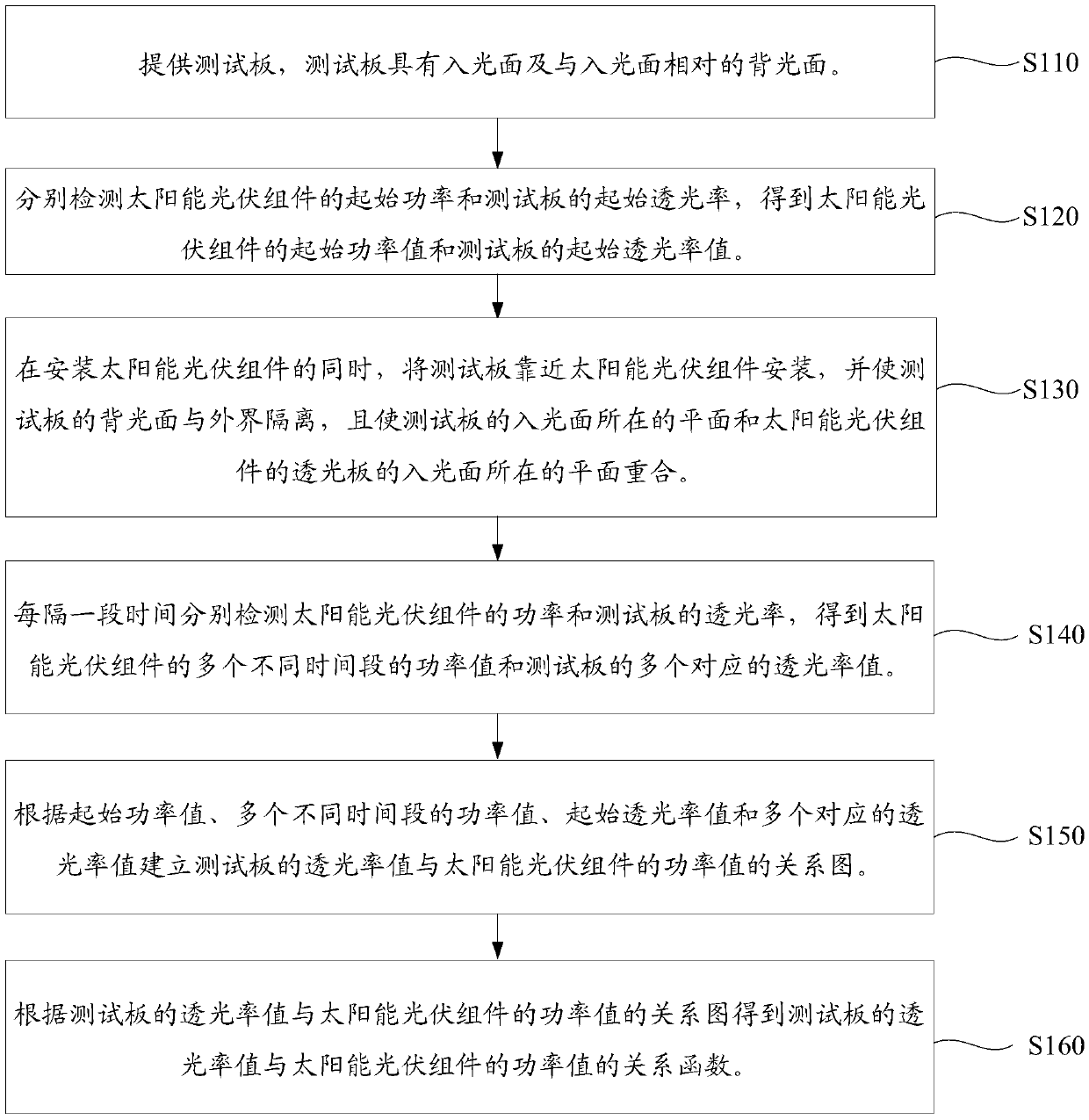

[0056] The specific process of the assay method of the cleaning cycle of the solar photovoltaic module of the present embodiment is as follows:

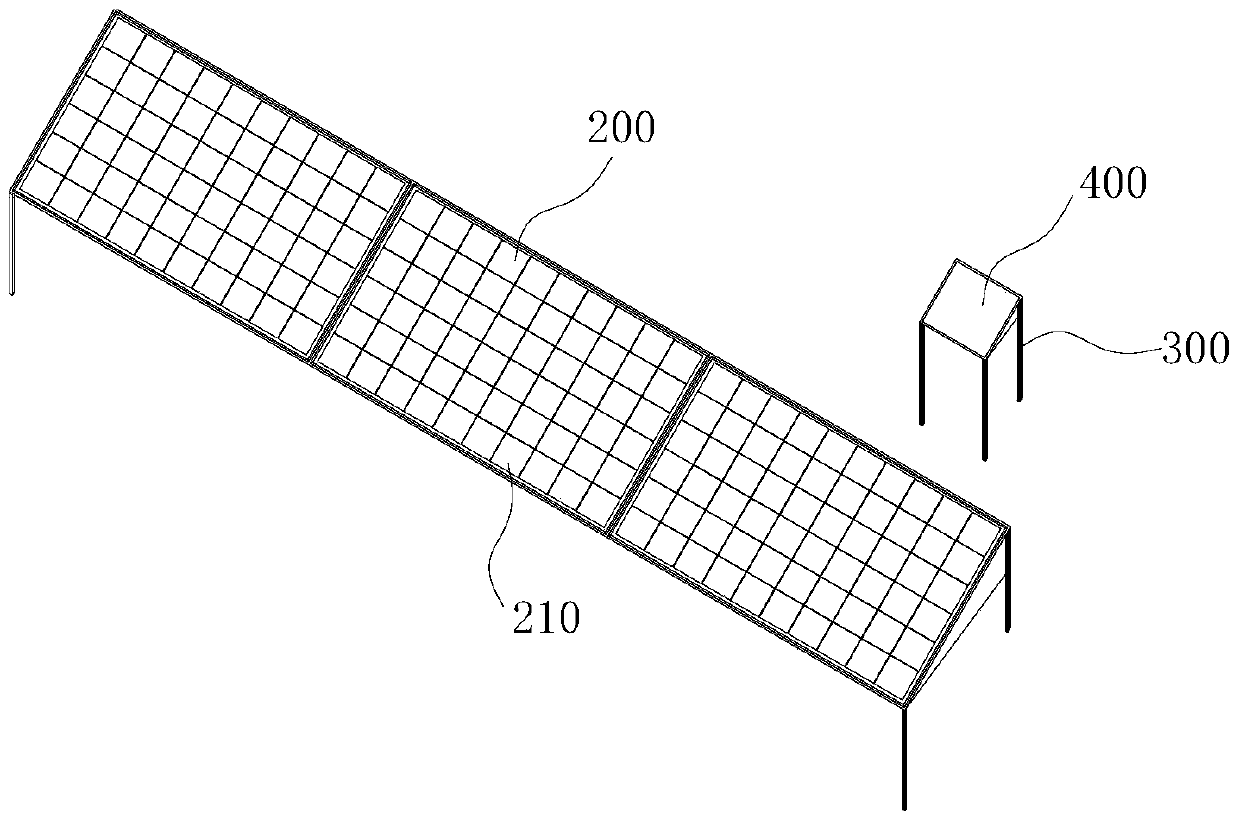

[0057] (1) The test board is prepared according to the preparation process of the light-transmitting plate of the solar photovoltaic module, wherein both the light-transmitting plate and the test plate are glass substrates.

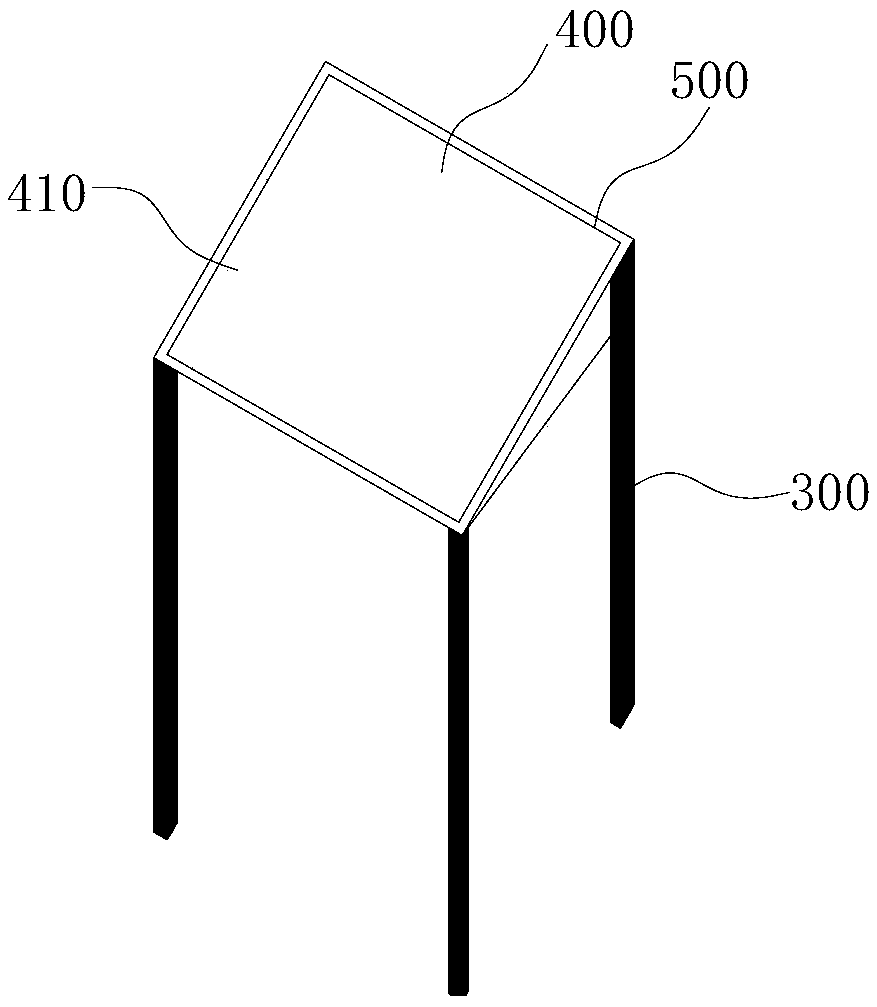

[0058] (2) Set the second frame around the edge of the test board on the test board. The materials of the second frame and the first frame around the edge of the solar photovoltaic module are both aluminum, and the second frame is higher than the entrance of the test board. The height from one side of the light surface to the light-incident surface of the test board is equal to the height from the side of the first frame higher than the light-incident surface of the light-transmitting plate of the solar photovoltaic module to the light-incident surface of the light-transmitting plate, and the height of the second...

Embodiment 2

[0069] The specific process of the assay method of the cleaning cycle of the solar photovoltaic module of the present embodiment is as follows:

[0070] (1) The test board is prepared according to the preparation process of the light-transmitting plate of the solar photovoltaic module, wherein both the light-transmitting plate and the test plate are glass substrates.

[0071] (2) Set the second frame around the edge of the test board on the test board. The materials of the second frame and the first frame around the edge of the solar photovoltaic module are both aluminum, and the second frame is higher than the entrance of the test board. The height from one side of the light surface to the light-incident surface of the test board is equal to the height from the side of the first frame higher than the light-incident surface of the light-transmitting plate of the solar photovoltaic module to the light-incident surface of the light-transmitting plate, and the height of the second...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap