Method for producing a polyolefin structure

一种聚烯烃系、制造方法的技术,应用在聚烯烃系结构物的制造领域,能够解决飞散于大气中等问题,达到阻隔性能优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 101

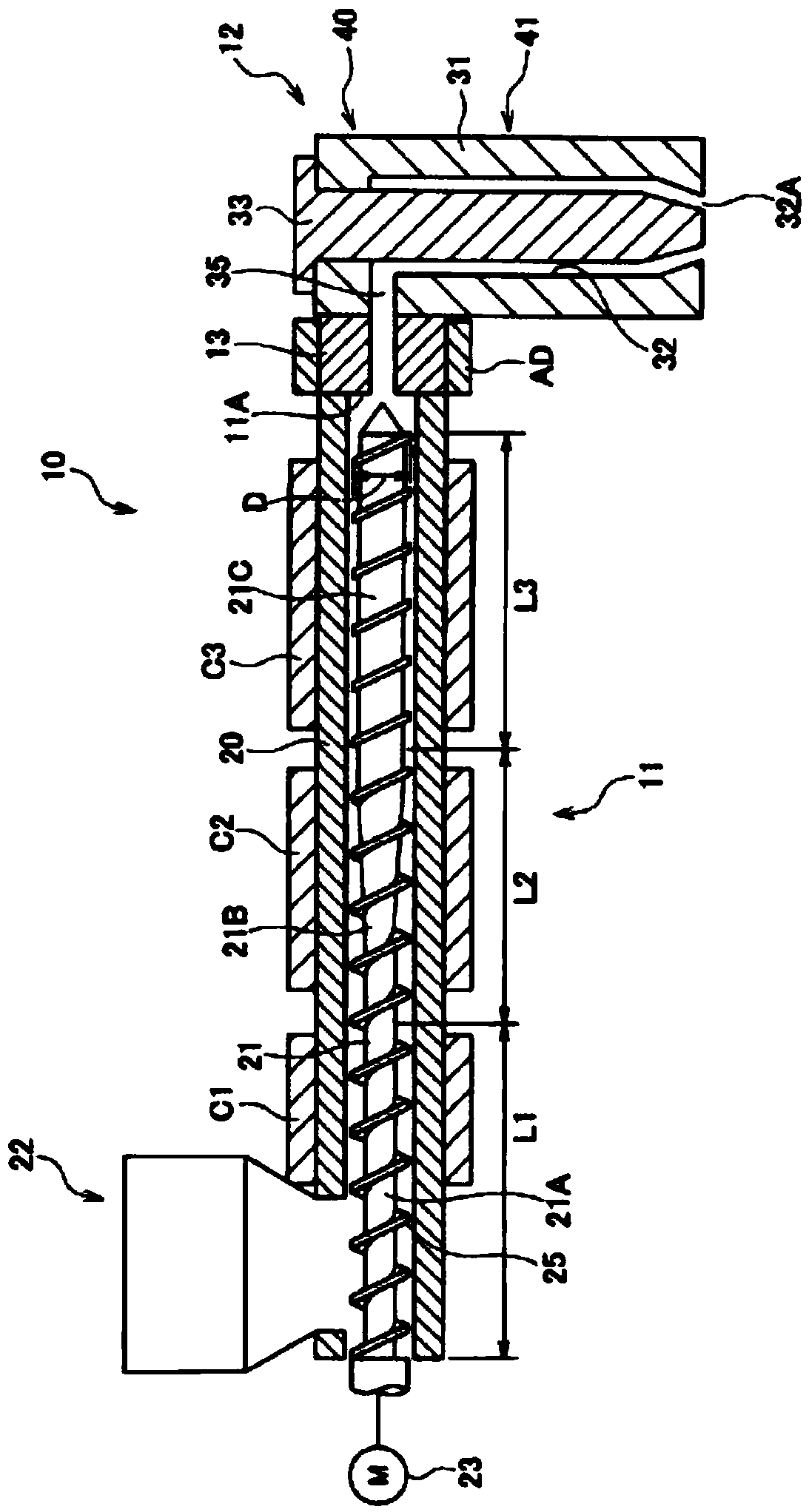

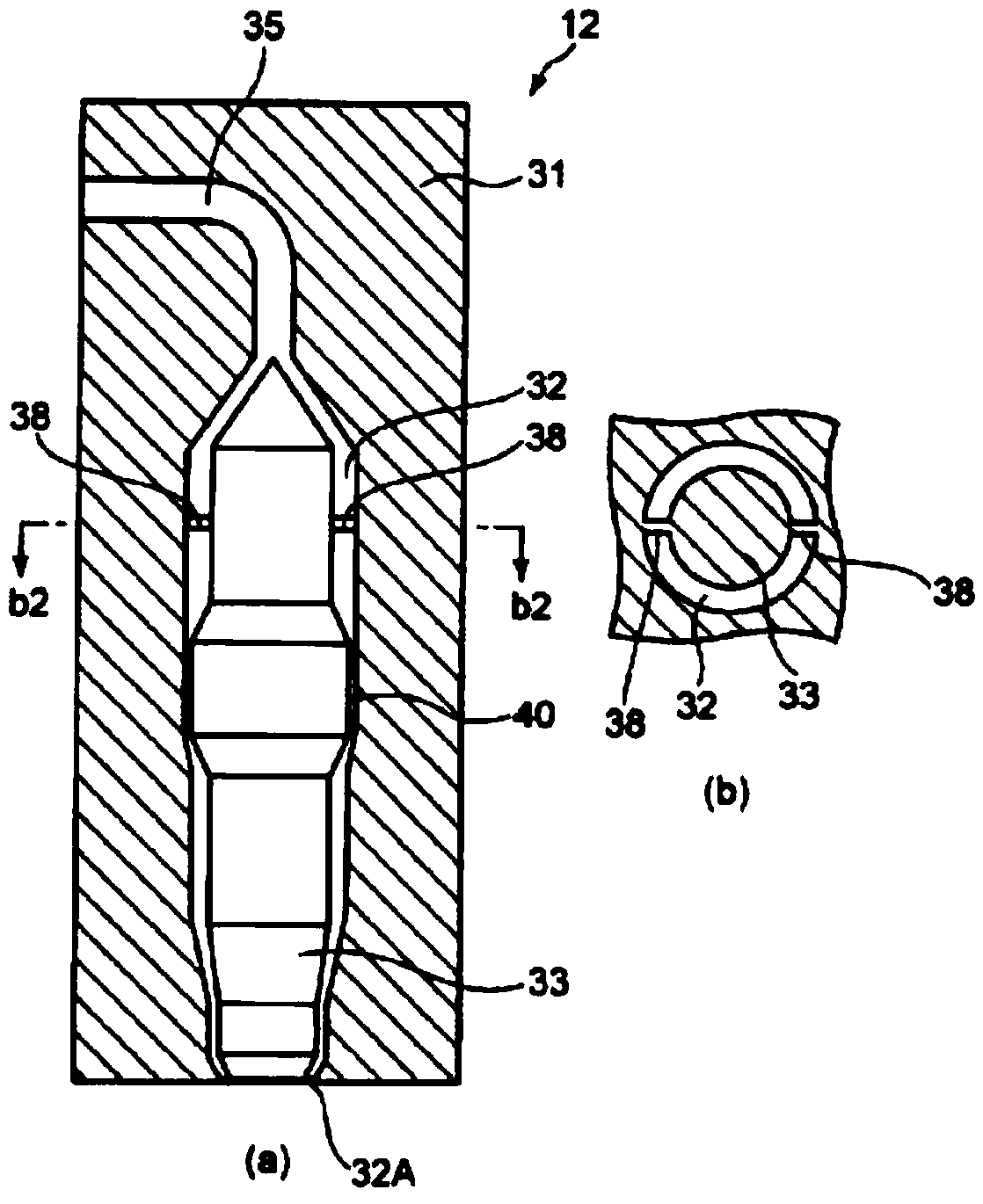

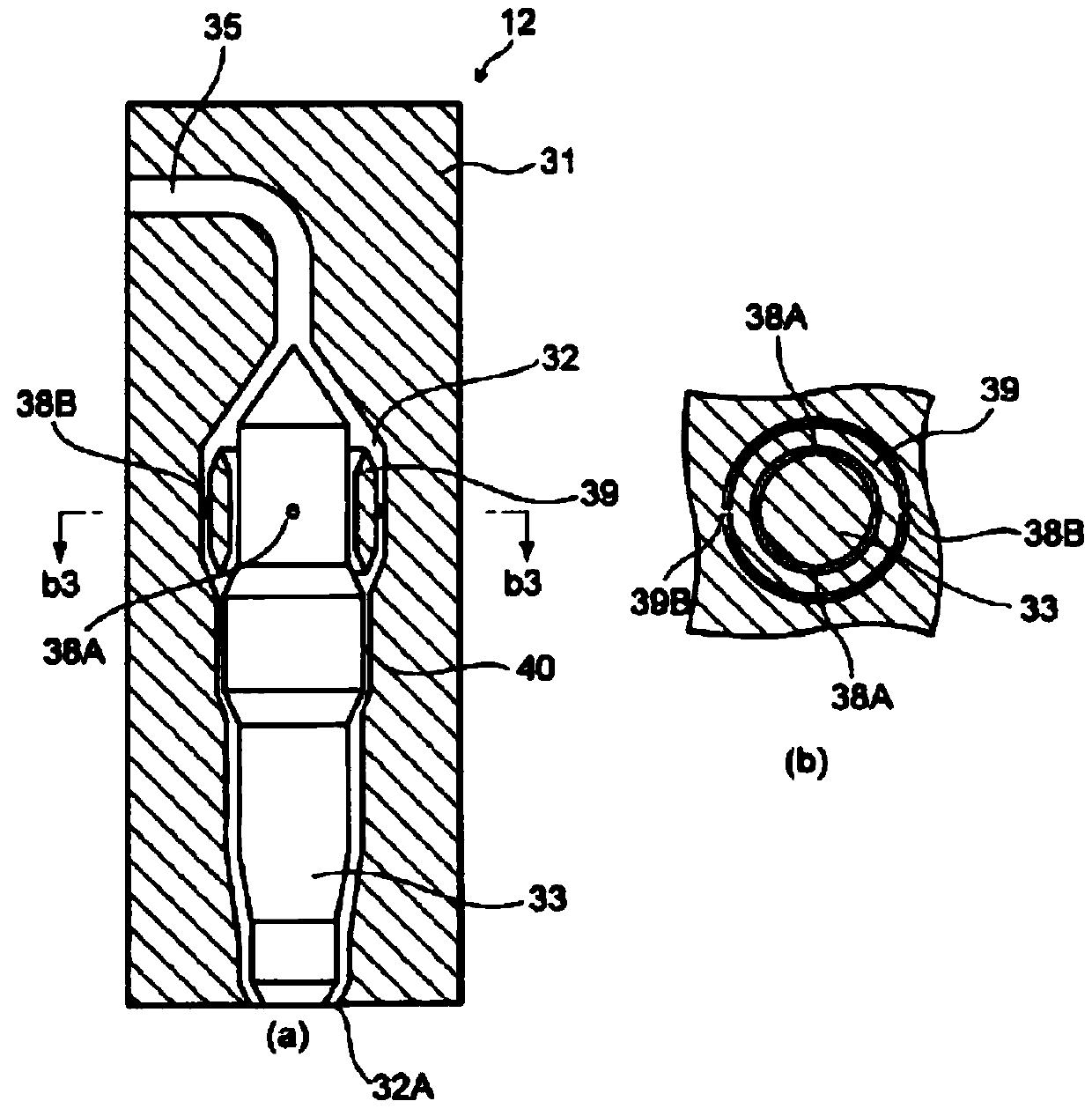

[0239]A single-screw extruder equipped with a full-flight screw inserted with a diameter=50mm, L / D=25, length ratio of supply part / compression part / measurement part=33 / 33 / 33%, compression ratio=2.5, transfer A single-layer direct blow container molding machine, such as a cylinder mold with a parison adjuster (die head; the width of the narrowest part of the die hole: 1mm), a mold, a mold clamping machine, and a cooler, is molded as follows bottle. From the extruder hopper with the ratio of HDPE-1 / AD-1 / PA-1=80 / 10 / 10 (mass %), the mixed particles of dry mixing are dropped into the single-screw extruder, and the screw speed is set to 30 rpm, the parison was extruded from the cylinder die, and a bottle with a threaded plug with an inner volume of 400 ml and a thickness of 1 mm was formed by direct blow molding. At this time, the barrel temperature of the extruder was set to C1 / C2 / C3=180 / 190 / 230°C, the temperature of the adapter was set to 240°C, and the temperature of the die was...

Embodiment 102~109

[0242] Except that the types, compounding amounts, and respective set temperatures of the polyolefin (A), acid-modified polyolefin (B), and gas barrier resin (C) were changed as shown in Table 1, the procedure was carried out in the same manner as in Example 101. , for the molding of bottles with screw caps.

[0243] The toluene transmission rate measurement and the drop test were implemented about the obtained bottle. The results are shown in Table 1.

Embodiment 110

[0245] Except that the container and overflow produced in Example 101 were pulverized and dry-blended at the ratio of HDPE-1 / AD-1 / PA-1 / crushed product=48 / 6 / 6 / 40 (mass %), the same as Example 101 101 is similarly operated to form a bottle with a screw cap.

[0246] The toluene transmission rate measurement and the drop test were implemented about the obtained bottle. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt Flow Rate | aaaaa | aaaaa |

| Melt Flow Rate | aaaaa | aaaaa |

| free volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com