Monitoring device for loom, loom and monitoring method

A technology for monitoring devices and looms, applied in looms, auxiliary weaving equipment, textiles, etc., can solve the problems that textile defects cannot be detected, and the time between the first appearance and the detection of the same defect is difficult to detect, etc., to achieve high precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

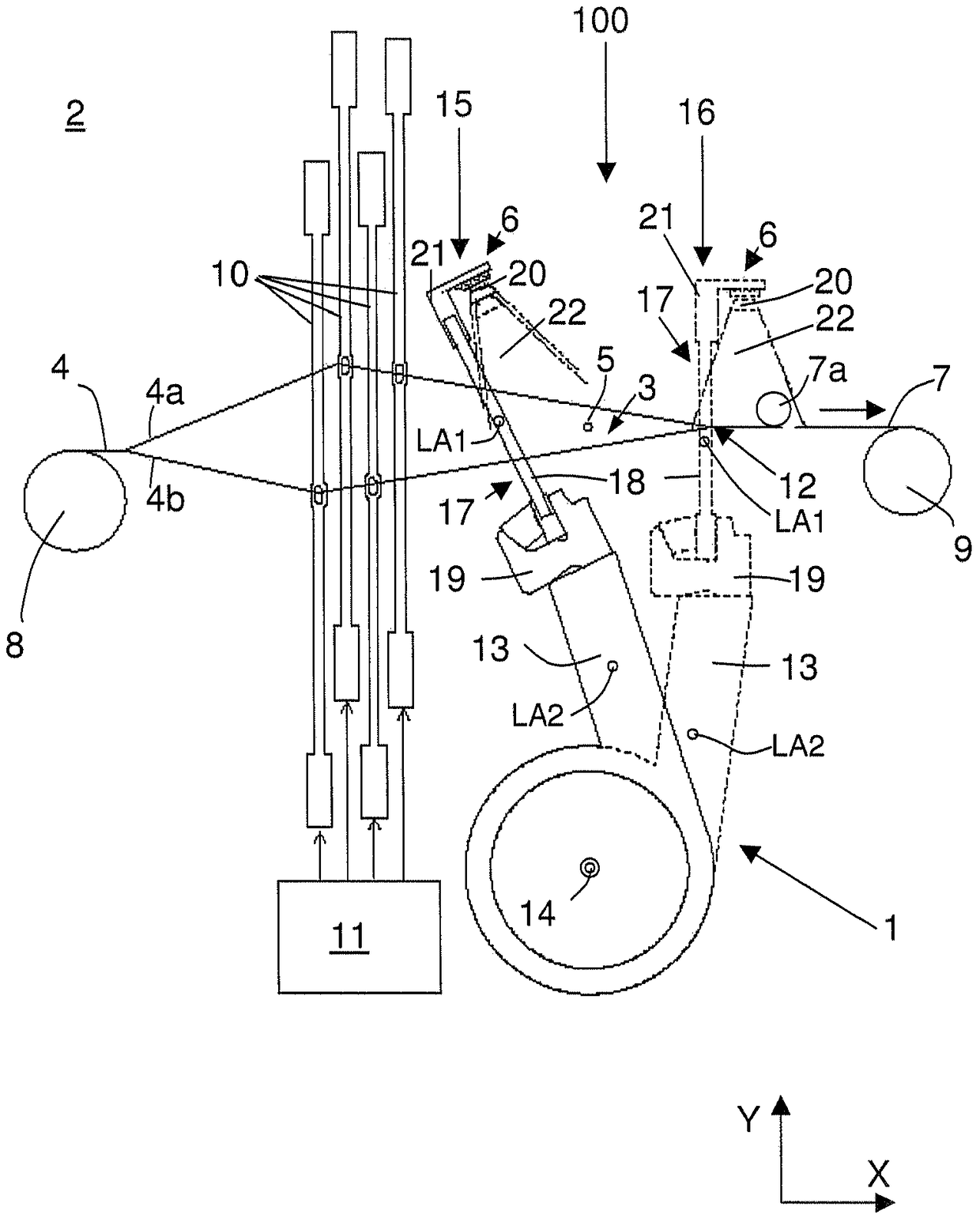

[0079] figure 1 shows a first exemplary embodiment of a monitoring device for a loom 2 in combination with a weft thread beating device 1 . The weaving machine 2 is shown only schematically, wherein the figure emphasizes the fabric-forming region 3 formed by the warp threads 4 . According to the above proposal, the weft thread beating device 1 is additionally provided with a camera device 6 for detecting the warp thread 4 and the weft thread 5 to be woven or the woven fabric 7, which will be explained in more detail later.

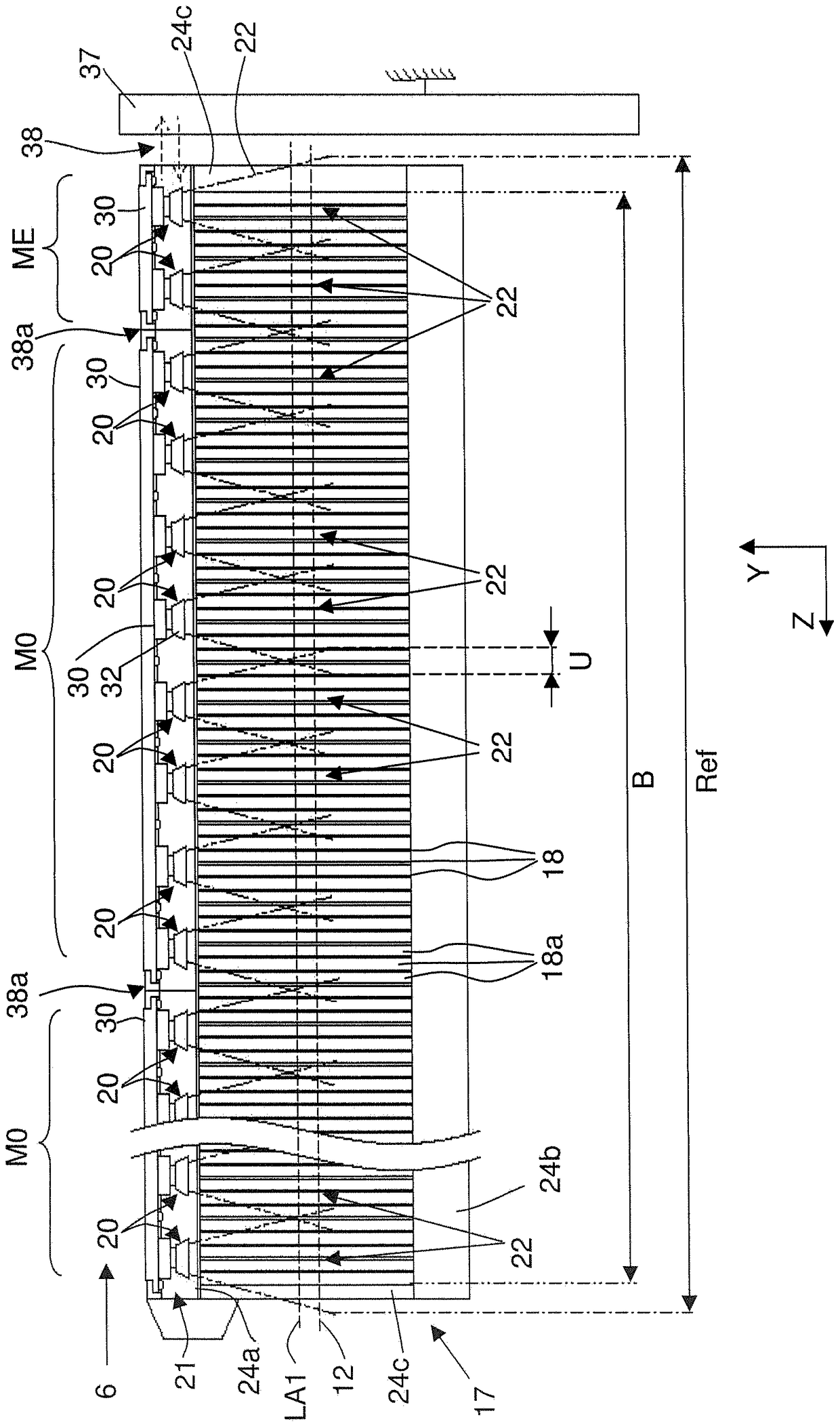

[0080] In this regard, refer to Figure 1-3 The shown coordinate system with coordinate axes X, Y and Z assumes that the direction of the weft thread 5 (weft direction) extends along the coordinate axis Z and that the fabric 7 is arranged parallel to the plane formed by the coordinate axes X and Z.

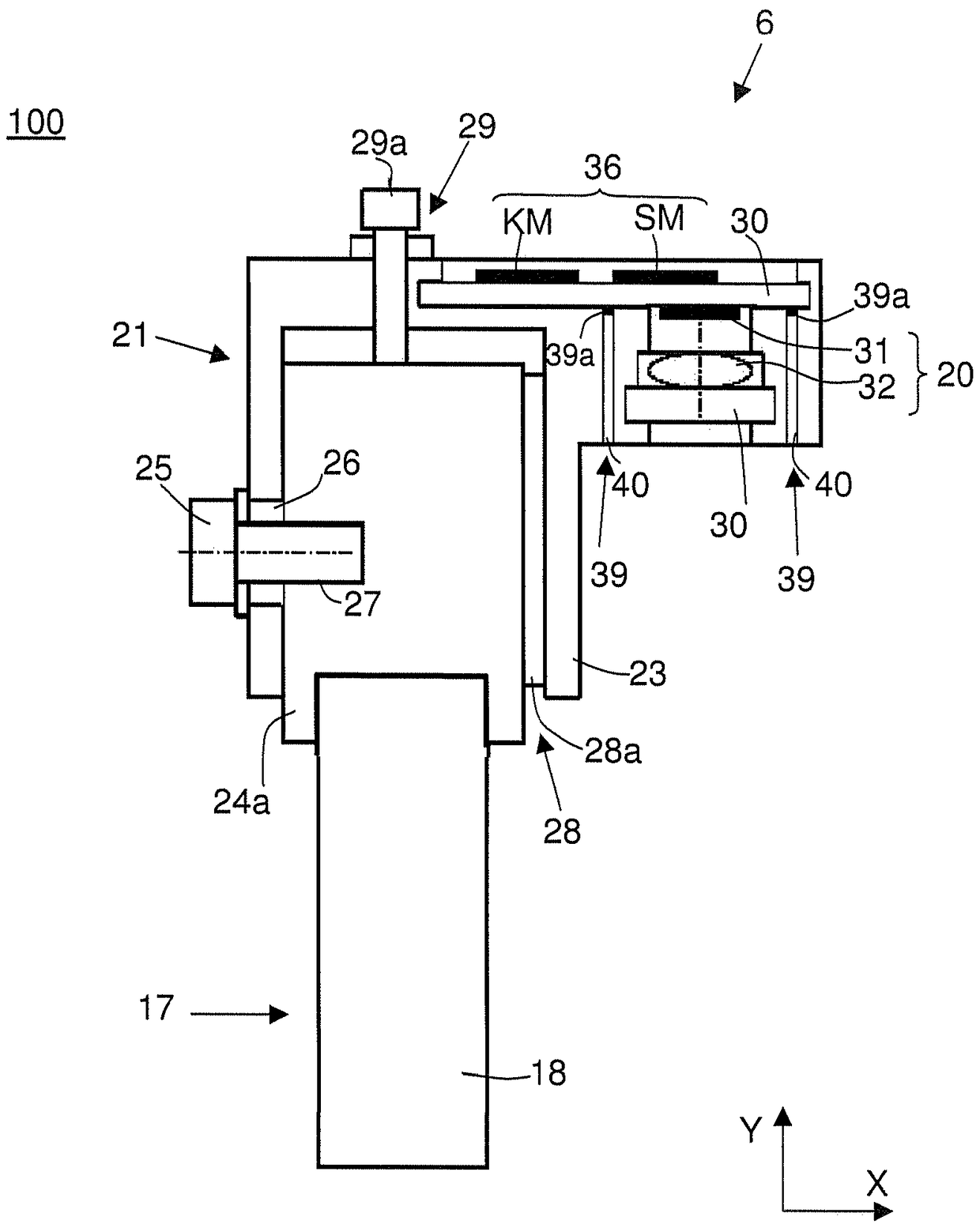

[0081] The camera arrangement 6 may comprise one or more camera devices 20 configured to record images. In the above example, the camera arrangement includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com