Chocolate liquor or product containing ergosterol extract and preparation method thereof

A chocolate pulp and ergosterol technology, applied in food ingredients containing natural extracts, food science, food ingredients, etc., to improve blood circulation and cardiovascular health, alleviate health risks, and reduce the risk of thrombosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

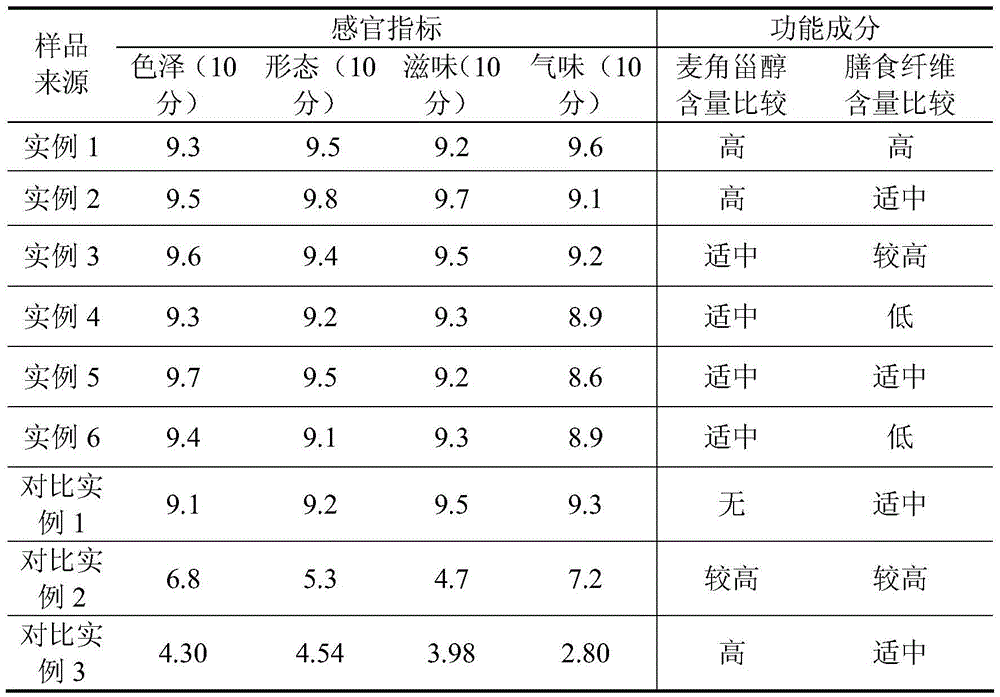

Examples

Example Embodiment

[0021] Example 1

[0022] Recipe: 20% chocolate, 10% skimmed milk powder, 2% lecithin, 1% sucralose, 22% laver superfine powder, 5% konjac superfine powder, 10% natto superfine powder, 25% strawberry freeze-dried superfine powder, 5% % Ergosterol Extract.

[0023] Preparation Process:

[0024] (1) Take 50kg shiitake mushrooms and undergo ultrafine grinding treatment, the crushed particle size is 15μm, add edible alcohol to a material-to-liquid ratio of 1:5, soak for 8 hours, and perform ultrasonic treatment for the first time. The ultrasonic frequency is 50kHz, the ultrasonic power is 300W, and the ultrasonic time is 7min, after the liquid slag is separated, the mushroom residue is added with edible alcohol with a material-to-liquid ratio of 1:3, soaked for 3 hours, and then ultrasonically treated for the second time, with an ultrasonic frequency of 70Hz, an ultrasonic power of 400W, and an ultrasonic time of 8min. Concentrate by rotary evaporation, wash the concentrate with...

Example Embodiment

[0028] Example 2

[0029] Formula: 45% chocolate, 7% skimmed milk powder, 1.5% lecithin, 0.8% sucralose, 18% laver superfine powder, 5.7% konjac superfine powder, 13% natto superfine powder, 5% strawberry freeze-dried superfine powder, 4 % Ergosterol Extract.

[0030] Preparation Process:

[0031](1) Take 50kg of shiitake mushroom stalks and undergo ultrafine grinding treatment, the crushed particle size is 17μm, add edible alcohol to a material-liquid ratio of 1:6, soak for 7 hours, and perform the first ultrasonic treatment with an ultrasonic frequency of 80kHz and an ultrasonic power of 400W. Time 6min, after liquid slag separation, mushroom slag plus edible alcohol material-liquid ratio is 1:4, soak for 2.5 hours, the second ultrasonic treatment, ultrasonic frequency 100Hz, ultrasonic power 450W, ultrasonic time 10min, combine the two extracts , concentrated by rotary evaporation, and the concentrated solution was washed with deionization, and vacuum-dried to obtain ergo...

Example Embodiment

[0035] Example 3

[0036] Formula: 46.7% chocolate, 3% skimmed milk powder, 0.7% lecithin, 0.6% sucralose, 25% superfine seaweed powder, 8% superfine konjac powder, 5% superfine natto powder, 9% strawberry freeze-dried superfine powder, 2 % Ergosterol Extract.

[0037] Preparation Process:

[0038] (1) Take 50kg of shiitake mushrooms and go through superfine crushing treatment, the crushed particle size is 15μm, add edible alcohol with a material-to-liquid ratio of 1:5.5, soak for 6 hours, and perform the first ultrasonic treatment with an ultrasonic frequency of 140kHz and an ultrasonic power of 500W , ultrasonic time 5min, after liquid slag separation, mushroom slag plus edible alcohol material-liquid ratio is 1:4.5, soak for 2 hours, ultrasonic treatment for the second time, ultrasonic frequency 50Hz, ultrasonic power 250W, ultrasonic time 6min, combined twice The extract was concentrated by rotary evaporation, and the concentrated solution was washed with deionization an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Grinding particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap