Positioning and straightening mechanism

A straightening and vertical technology, applied in metal processing machinery parts, measuring/indicating equipment, metal processing equipment, etc., can solve problems such as complicated operation and affecting work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The illustrated embodiments will be described in detail below in conjunction with the accompanying drawings.

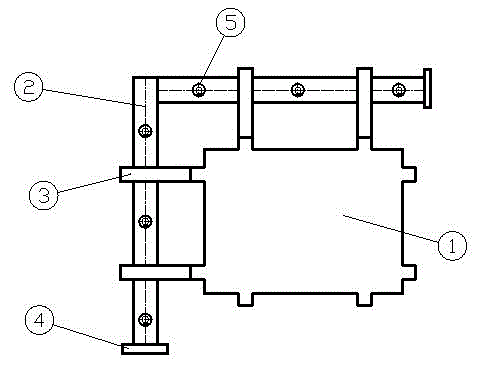

[0008] figure 1 A positioning and straightening mechanism provided by the present invention includes: a special-shaped workpiece (1), a guide rail (2), a slider (3), a stopper (4), and an inner hexagonal screw (5).

[0009] The implementation method is to fix the vertical direction of the guide rail (2) on the left side of the workbench of the machining center with 3 hexagon socket screws (5), and make the other guide rail (2) 90° from the vertical direction and use 3 screws The inner hexagon screw (5) is fixed on the top of the workbench of the machining center, and the length can be determined according to the size of the workbench. Install the sliders (3) on the guide rails one by one, and install two sliders on each guide rail. (Compared to large-scale machining centers, if the guide rails are too long, consider installing 3-4.) Install the stopper (4) at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com