Drive-amount changing mechanism for crank driving apparatus

A technology of driving device and changing mechanism, applied in the direction of transmission device, loom, mechanical equipment, etc., can solve the problems of accurate and consistent eccentricity, adverse weaving effect, operator burden, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

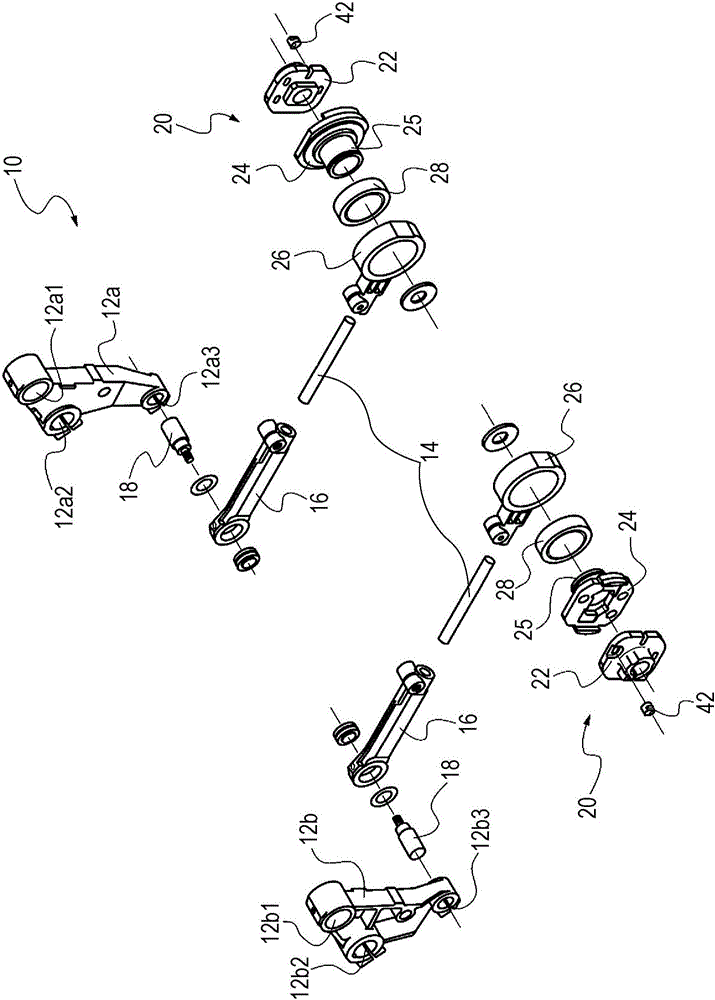

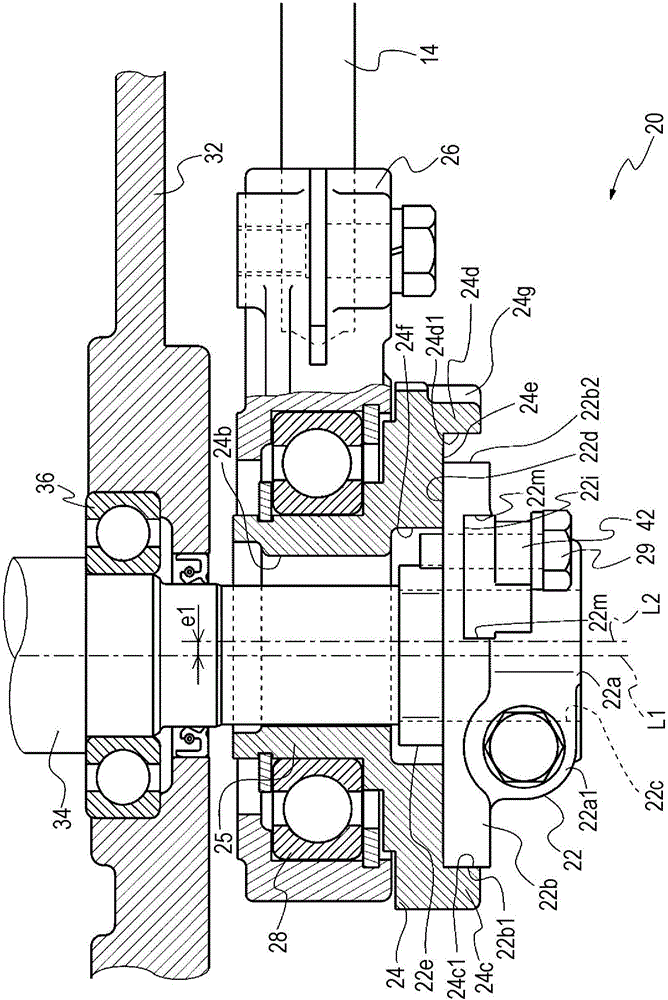

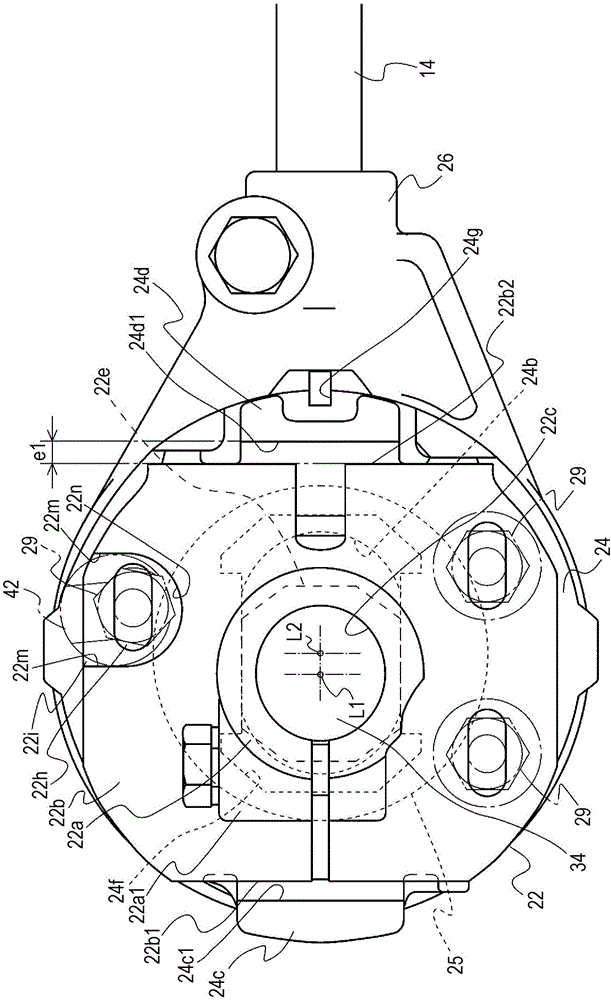

[0036] Hereinafter, embodiments of the present invention will be described in detail based on the drawings. Figure 1 to Figure 6 One embodiment of the present invention is shown, that is, a case where the crank type driving device provided with the driving amount changing mechanism according to the present invention is applied to an easing device of a loom.

[0037] figure 1 The outline of the easing device of the loom to which the present invention is applicable is shown, that is, the easing device 10 includes a pair of easing rods 12a for supporting a tension roller (not shown) around which a warp yarn is wound. .

[0038] Each of the easing bars 12a, 12b is rotatably supported on the loom frame via support shafts (not shown) inserted in support holes 12a1, 12bl formed at the upper ends of the respective easing bars 12a, 12b. Moreover, the shaft parts of both ends of a tension roller are fitted and fixed to the support hole 12a2, 12b2 formed in the intermediate part of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com