Electric-nose-analysis-based determination method of tuna oil corruption degree in storage process

A technology of tuna oil and determination method, which is applied in the direction of testing food, material inspection products, etc., can solve the problems of long analysis time, poor sensory evaluation accuracy, no reports, etc., and achieve high detection efficiency, short detection time and simple operation Effect

Inactive Publication Date: 2016-04-27

ZHEJIANG OCEAN UNIV

View PDF4 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The accuracy of sensory evaluation is poor, and the evaluation results vary from person to person, while gas spectrometry-mass spectrometry technology has high costs and long analysis time, and the test results are basically the results of separated samples, which is difficult to represent the integrity of the samples

[0

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

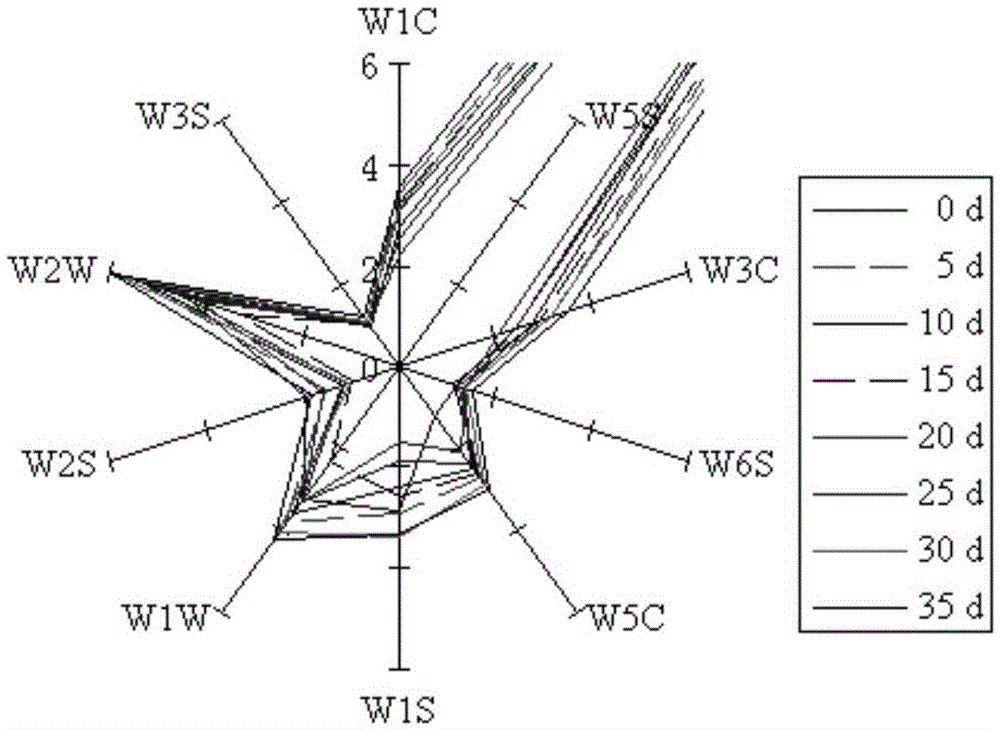

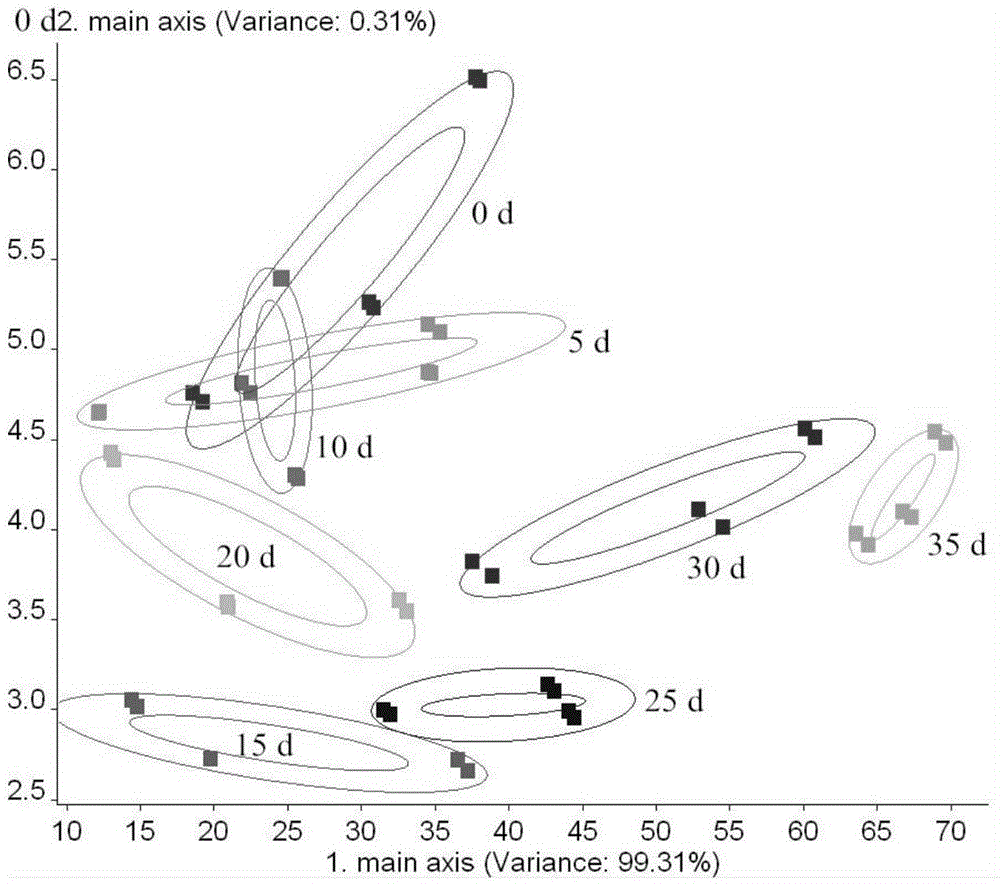

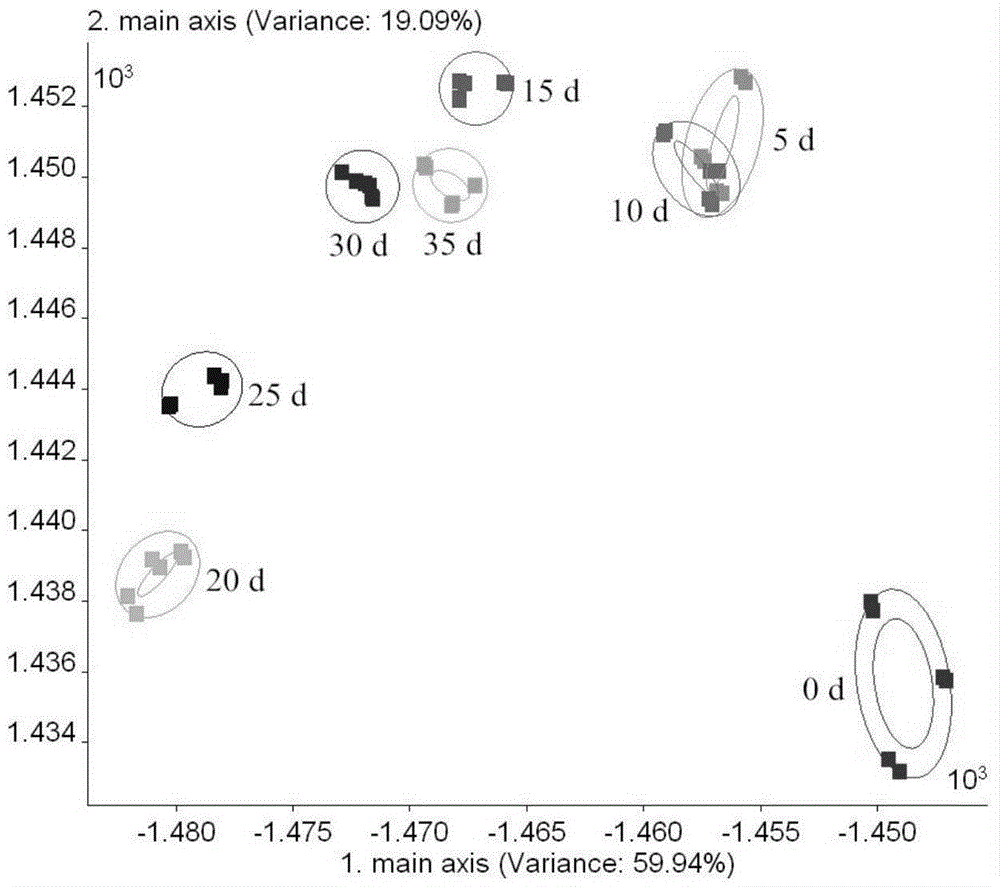

The present invention relates to an electric-nose-analysis-based determination method of tuna oil corruption degree in a storage process, according to the determination method, an electric-nose technology is used for research on volatile odor of tuna oil in the storage process, by principal component analysis (PCA) and linear discriminant analysis (LDA), fish oil samples of different storage time can be distinguished, and acid value and peroxide value forecast models can be established by partial least squares (PLS), so that the tuna oil corruption degree in the storage process can be effectively determined. Compared with the prior art, the determination method is simple in operation, short in detection time and high in detection efficiency, is a fast, effective and comprehensive determination of tuna oil quality, can be widely popularized in fish oil quality measurement.

Description

technical field [0001] The invention relates to the field of fish oil quality measurement, in particular to a method for measuring the corruption degree of tuna oil during storage based on electronic nose analysis. Background technique [0002] The electronic nose is composed of multiple chemical sensors with overlapping performance and appropriate pattern recognition methods, and can recognize simple and complex bionic instruments for odors. Similar to the noses of humans and animals, what the electronic nose "smells" is the overall information of the volatile components in the tested sample. When working, the gas sensor array adsorbs, desorbs or reacts to the gas, and generates an electrical signal, and then transfers the circuit and data acquisition system to amplify, A / D convert, collect and transmit the signal generated by the sensor, and finally sends it to To the computer and the pattern recognition system, carry out pattern recognition on the signal, make a judgment...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N33/03

CPCG01N33/03

Inventor 陈小娥方旭波陈娜赵小惠

Owner ZHEJIANG OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com