High voltage relay adhesion detection circuit of battery management system and detection method

A technology of battery management system and high-voltage relay, which is applied in the direction of circuit breaker testing, instrumentation, and electrical measurement. It can solve problems such as inability to disconnect in time, inability to detect high-voltage relay adhesion in a timely and effective manner, and affect the safety of power batteries. To achieve the effect of system power-off protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

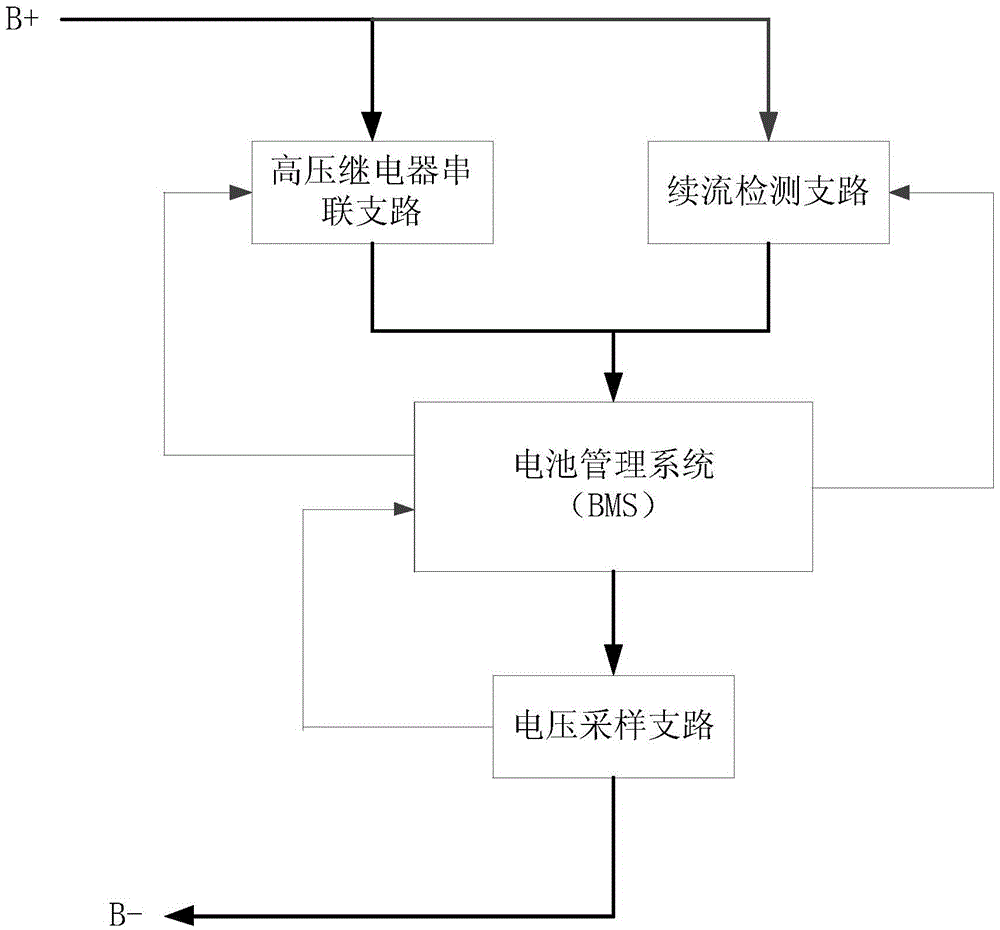

[0034] Embodiment 1 of the present invention provides a high voltage relay adhesion detection circuit of a battery management system. refer to figure 1 , the high voltage relay adhesion detection circuit of the battery management system includes:

[0035] High voltage relay series branch, freewheeling detection branch, voltage sampling branch and battery management system,

[0036] One end of the relay parallel branch composed of the high-voltage relay series branch and the freewheeling detection branch is connected to the total positive terminal of the power battery, and the other end is connected to the high-voltage line input end of the battery management system, and the high-voltage line output end of the battery management system is connected in series for voltage sampling The branch is connected to the total negative terminal of the battery, the series branch of the high voltage relay includes more than one total positive relay connected in series, the freewheel detecti...

Embodiment 2

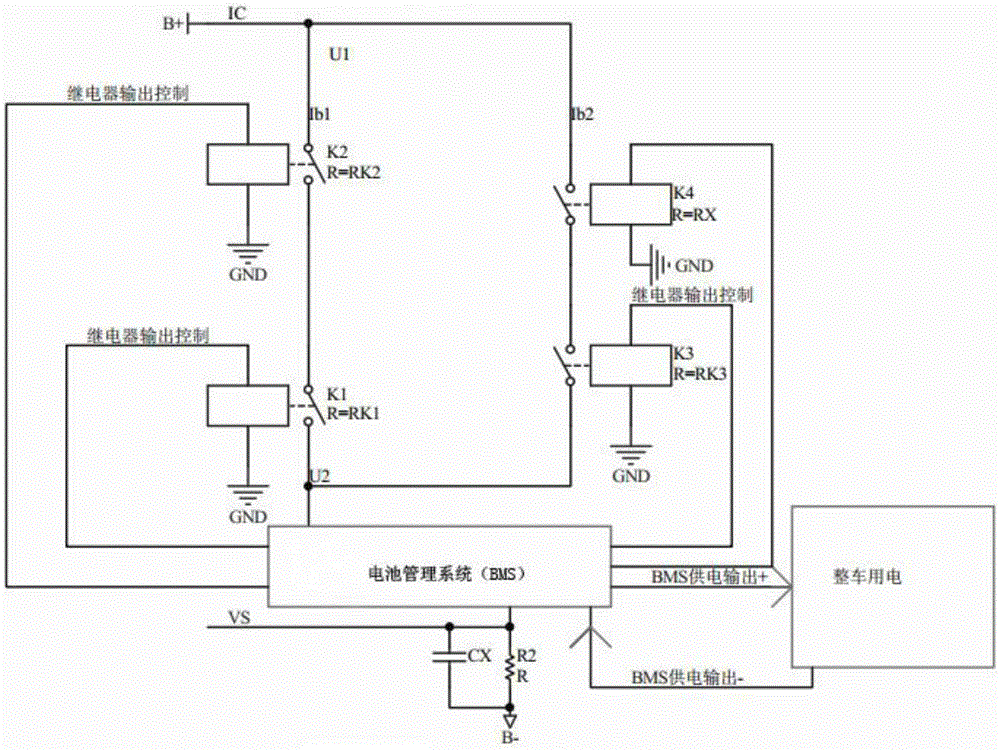

[0038] Embodiment 2 of the present invention provides a high voltage relay adhesion detection circuit of a battery management system, which is an improvement on the basis of Embodiment 1. refer to figure 2 , the high voltage relay adhesion detection circuit of the battery management system includes:

[0039] High voltage relay series branch, freewheeling detection branch, voltage sampling branch and battery management system.

[0040] One end of the relay parallel branch composed of the high-voltage relay series branch and the freewheeling detection branch is connected to the total positive terminal B+ of the power battery, and the other end is connected to the high-voltage line input terminal of the battery management system. The high-voltage relay series branch includes a first main positive relay K1 and a second main positive relay K2 connected in series. The freewheeling detection branch includes a first freewheeling relay K3, a second freewheeling relay K4 and a first ...

Embodiment 3

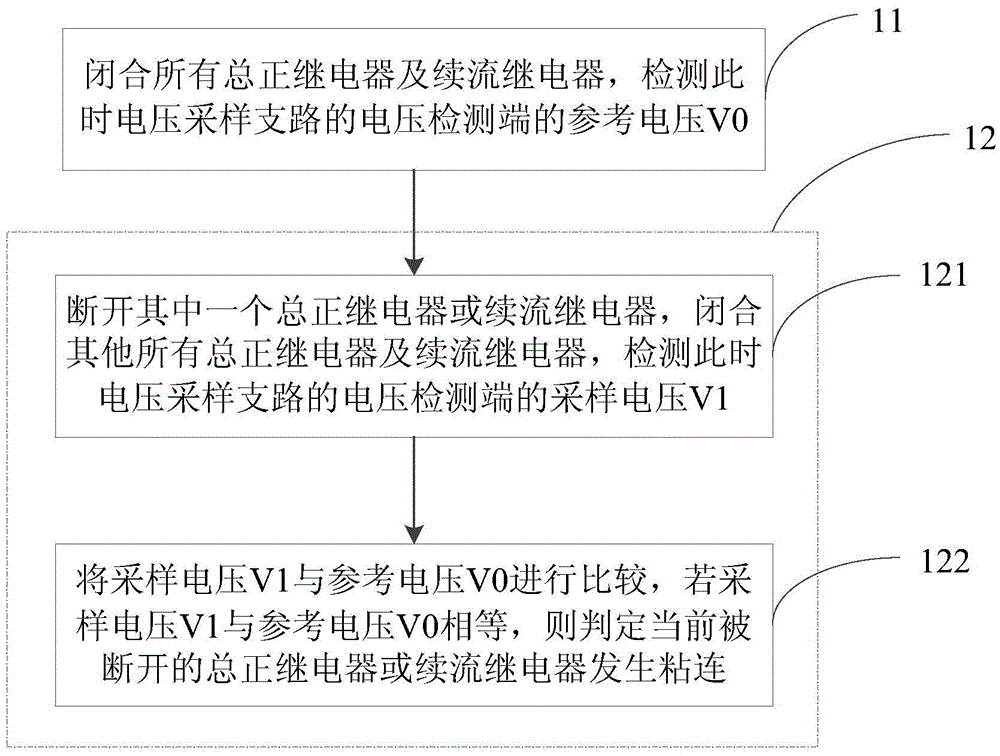

[0044] Embodiment 3 of the present invention provides a high-voltage relay adhesion detection method based on the high-voltage relay adhesion detection circuit of the battery management system in Embodiment 1. Refer to image 3 , the high voltage relay adhesion detection method of the battery management system includes the following steps:

[0045] 11 Close all the total positive relays and freewheeling relays, and detect the reference voltage V0 of the voltage detection terminal of the voltage sampling branch at this time;

[0046] 12 Carry out adhesion judgment on the total positive relay and freewheeling relay in turn, the process is as follows:

[0047] 121 Disconnect one of the total positive relays or freewheeling relays, close all other total positive relays and freewheeling relays, and detect the sampling voltage V1 of the voltage detection terminal of the voltage sampling branch at this time;

[0048] 122 compares the sampling voltage V1 with the reference voltage V0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com