A method of realizing one-way one-line communication between two plcs through i/o ports

A single-wire communication, one-way technology, applied in sequence/logic controller program control, general control system, control/regulation system, etc., can solve problems such as increased equipment cost, consumption, large PLC port, etc., to achieve control The effect of convenience, good practicability and simple communication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

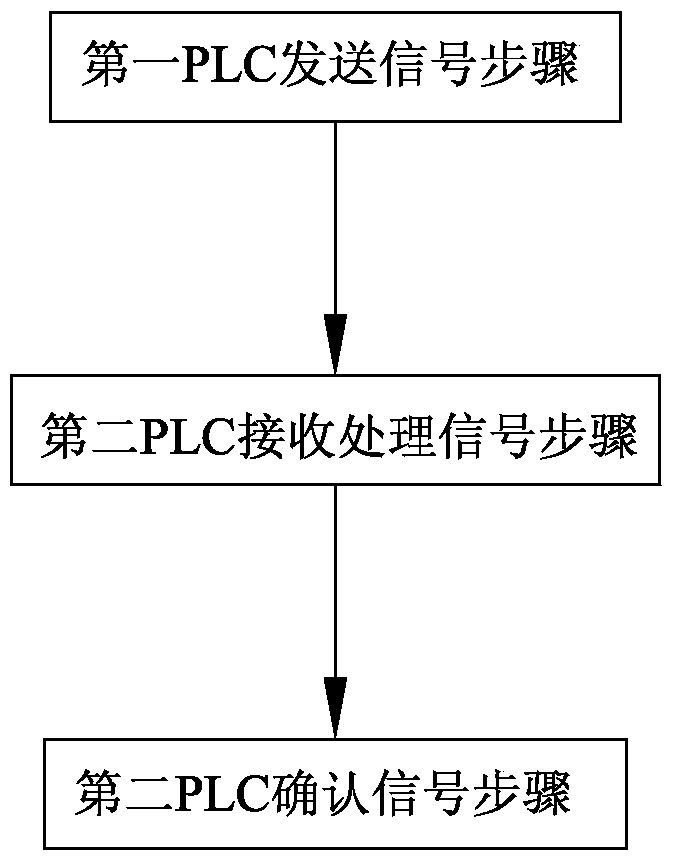

[0019] A method for realizing one-way single-line communication between two PLCs through an I / O port, wherein an I / O sending port of the first PLC is connected to an I / O receiving port of the second PLC through a communication line, The method includes a first PLC signal sending step, a second PLC receiving and processing signal step, and a second PLC confirming signal step,

[0020] The first PLC sending signal step includes: when the first PLC sends a communication signal, start timer T1 and timer T2 at the same time, timer T1 starts as the time for sending the signal, timer T2 as the deadline for sending the signal, timer T2 The timing time difference between timer T1 and timer T1 is recorded as the unit maximum sending time △T....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com