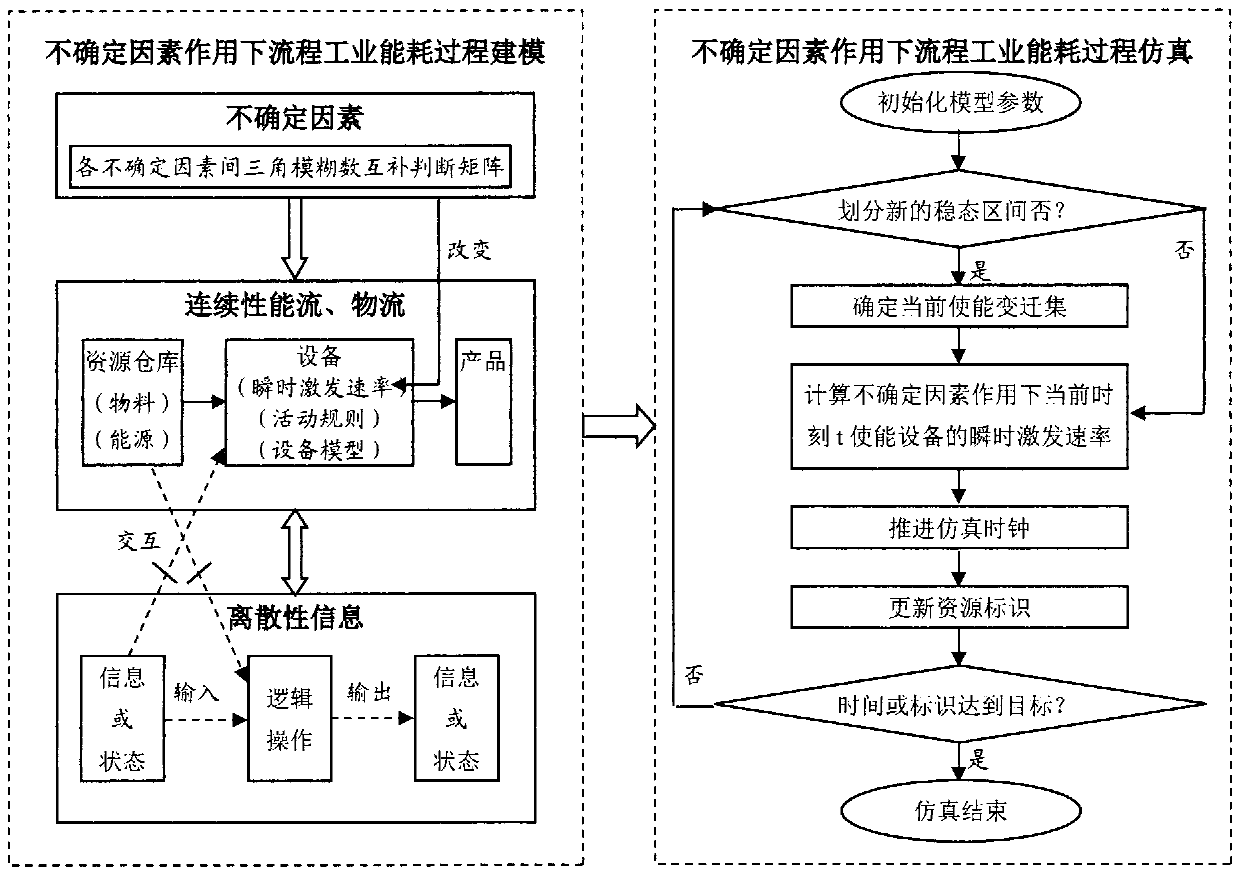

Modeling and simulation method of energy consumption process in process industry under the action of uncertain factors

A technology of process industry and simulation method, which is applied in special data processing applications, instruments, calculations, etc., and can solve problems such as deviation and simulation analysis results that cannot be truly reflected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

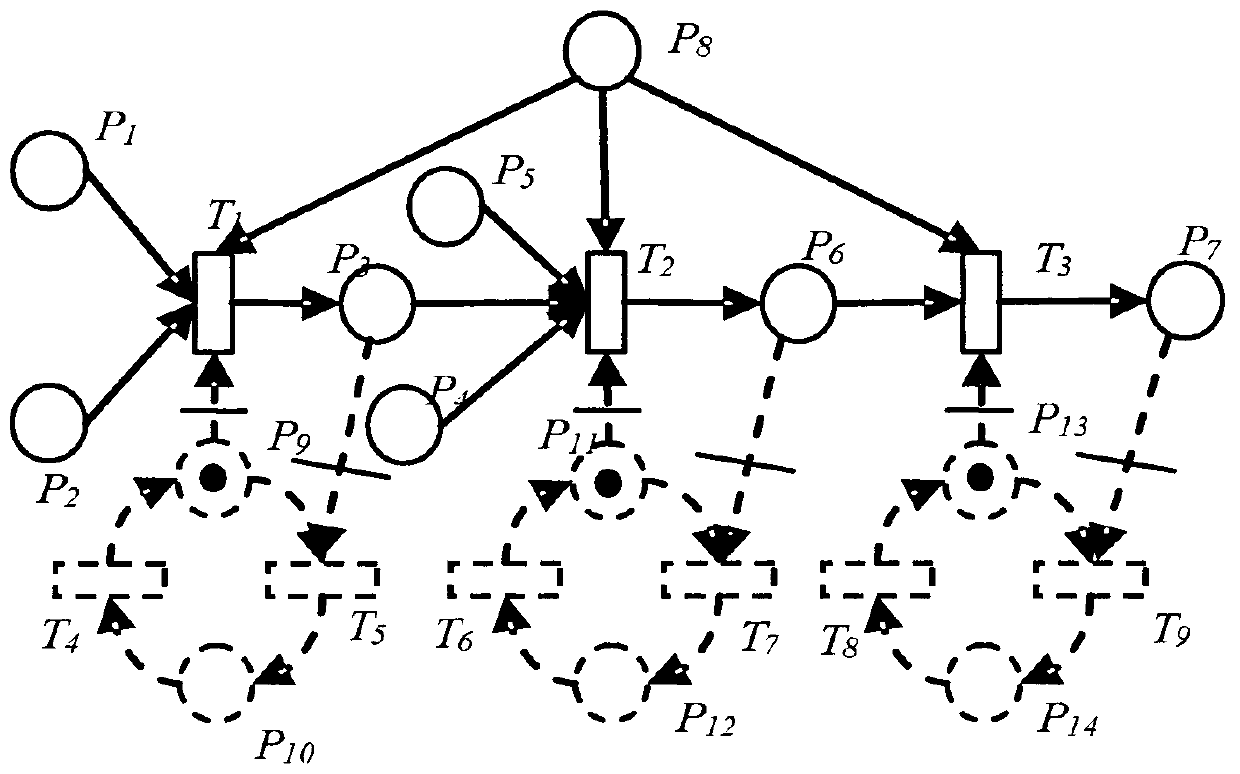

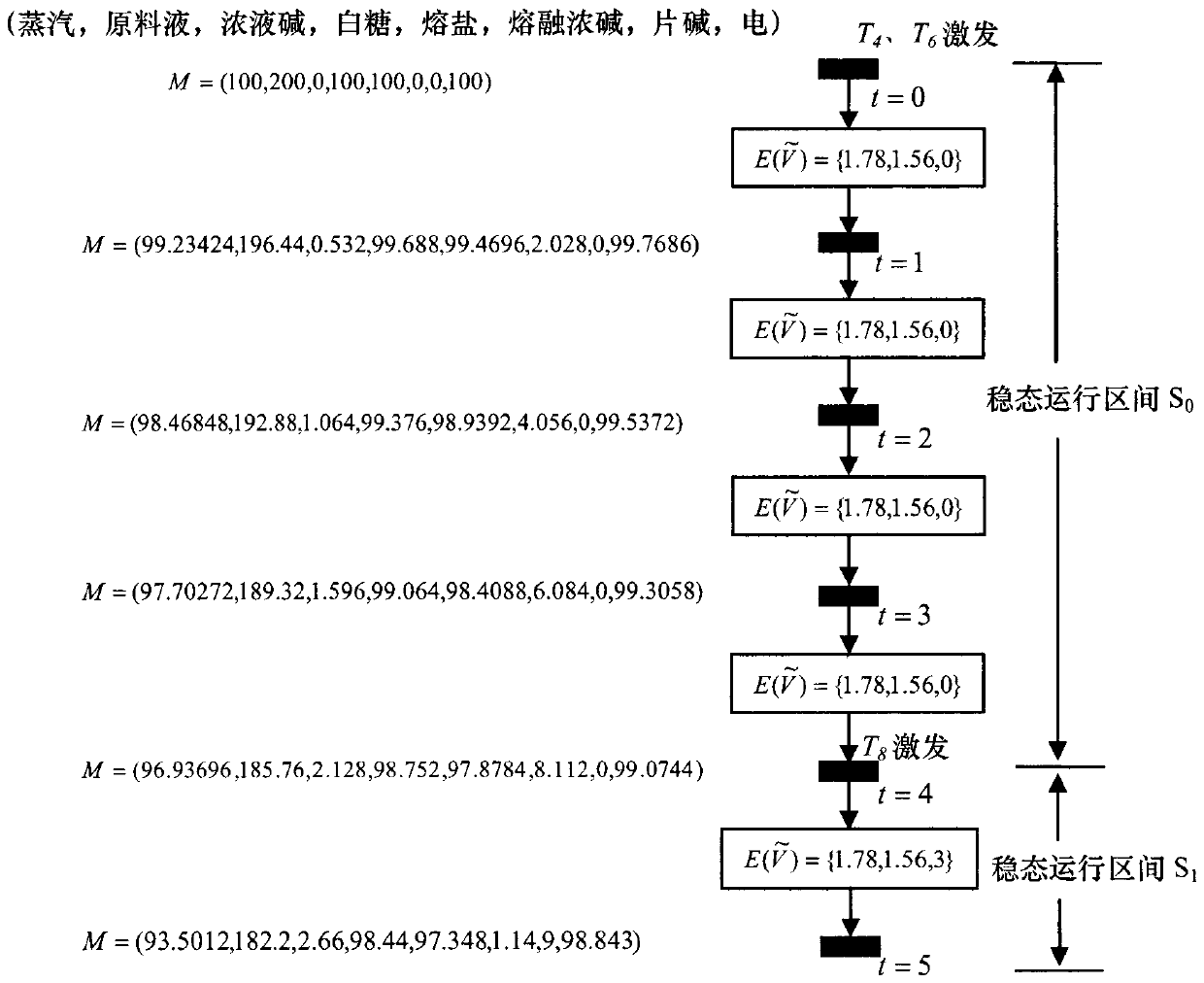

[0051] Implementation case: Take the production process of solid caustic soda with sheet-shaped ionic membrane as an example. The production process of ionic membrane solid caustic soda mainly involves three kinds of processing equipment, namely: rising film evaporator, falling film concentrator and caustic soda machine. The basic process of equipment cooperative production of caustic soda is as follows: the liquid caustic soda enters the rising film evaporator through the evaporation process, and is heated to boiling by steam to obtain a concentrated liquid caustic soda with a liquid caustic concentration of 60%. The high-temperature molten salt is heated until boiling, and after concentration, the molten concentrated alkali is obtained. After the molten concentrated alkali passes through the gas-liquid separator and the alkali distributor, the caustic soda machine is used to obtain caustic soda.

[0052] As stated in Definition 1, the excitation rate of each device is descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com