LED display screen uniformity correction method

A technology of LED display and uniformity correction, applied in static indicators, instruments, etc., can solve problems such as low brightness and brightness loss, achieve uniform brightness and improve display effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

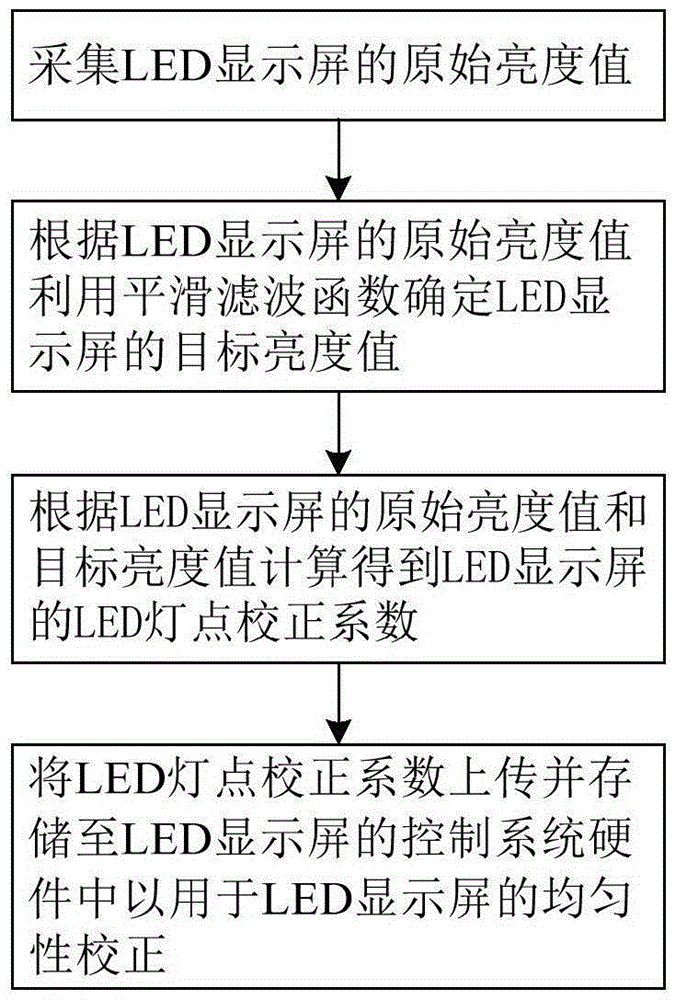

[0022] The method for correcting the uniformity of the LED display screen proposed by the first embodiment of the present invention is realized by the following steps, for example, and figure 1 Each step is shown in ; the LED display in this embodiment takes RGB full-color LED display as an example.

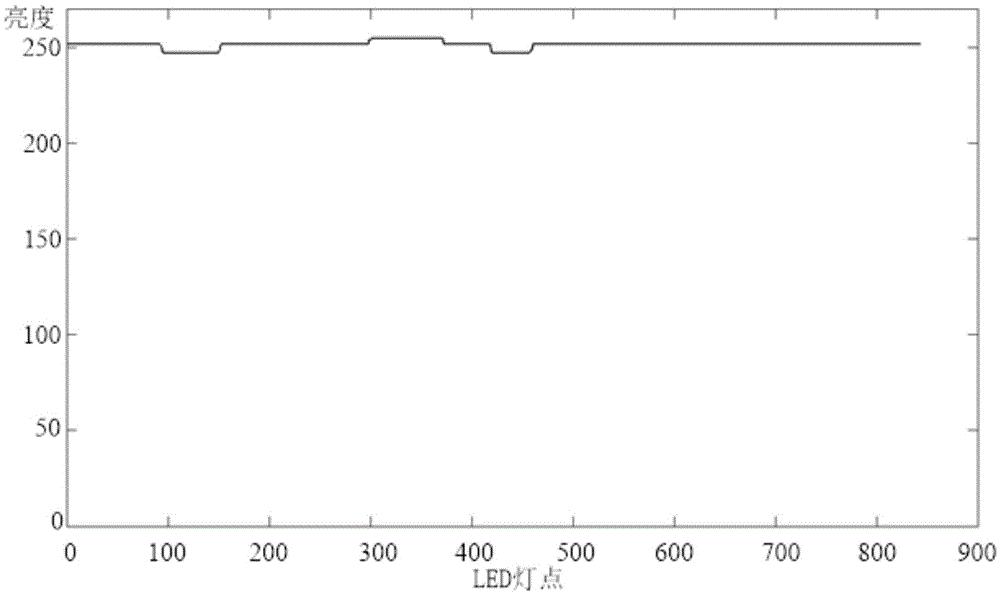

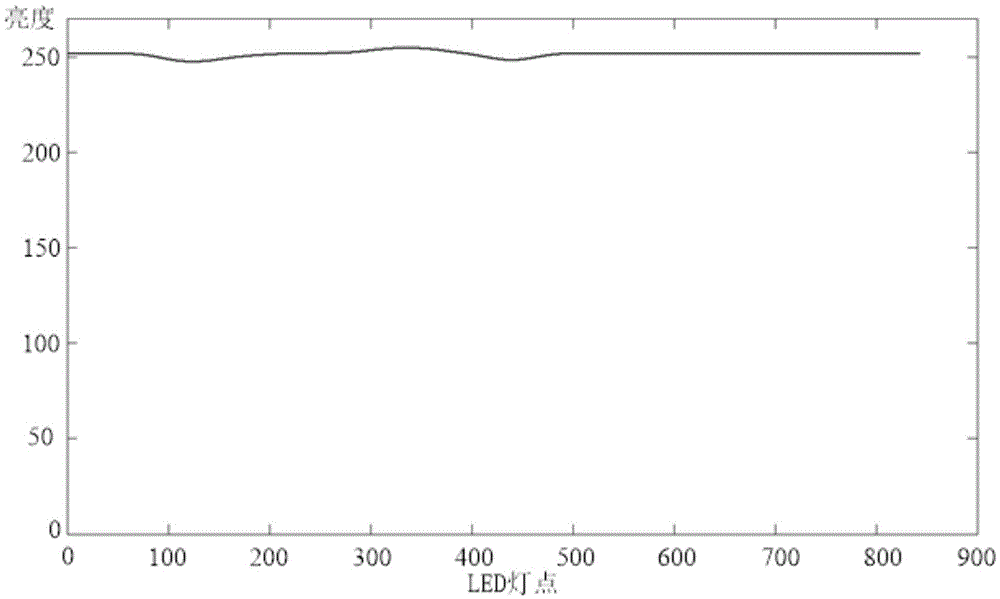

[0023] The first step is to collect the original brightness value of the LED display, specifically to control the LED display to display a variety of monochrome images in a preset order, that is, to display red (R) images, green (G) images and blue images in a preset order. Color (B) picture, wherein the red picture is formed by, for example, lighting up a plurality of red LED lamp points with the maximum brightness, and the green picture is formed, for example, by lighting up a plurality of green LED lamp points with the maximum brightness, and the blue picture is, for example, Formed by lighting multiple blue LED light spots at maximum brightness. And, in the process of displa...

no. 2 example

[0032] The method for correcting the uniformity of the LED display screen proposed in the second embodiment of the present invention is implemented by the following steps, for example. The LED display screen in this embodiment takes an RGB full-color LED display screen as an example.

[0033] The first step is to collect the original brightness value of the LED display, specifically to control the pure white picture of the LED display. formed by a blue LED light point. Moreover, in the process of displaying a pure white picture on the LED display screen, an image acquisition device such as a camera is used to capture the displayed pure white picture; and then the LED light of the LED display screen can be obtained by performing image processing on the captured pure white picture image. Point original brightness value, where the LED light point original brightness value refers to the original brightness value of each LED pixel point (typically composed of one RLED, one GLED and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com