Wear-resisting anti-skidding lifting device of crane beam

A lifting device and crane technology, applied in the field of cranes and lifting devices, can solve the problems of waste materials in production and processing, short trolley beams, low labor efficiency, etc., achieve high mechanical strength and wear resistance, reduce production costs, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

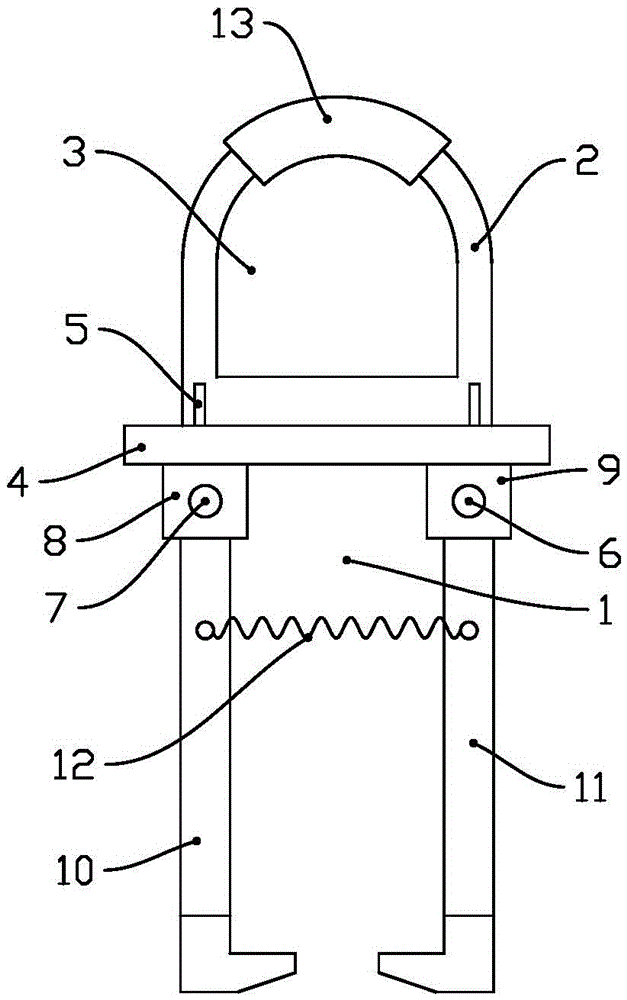

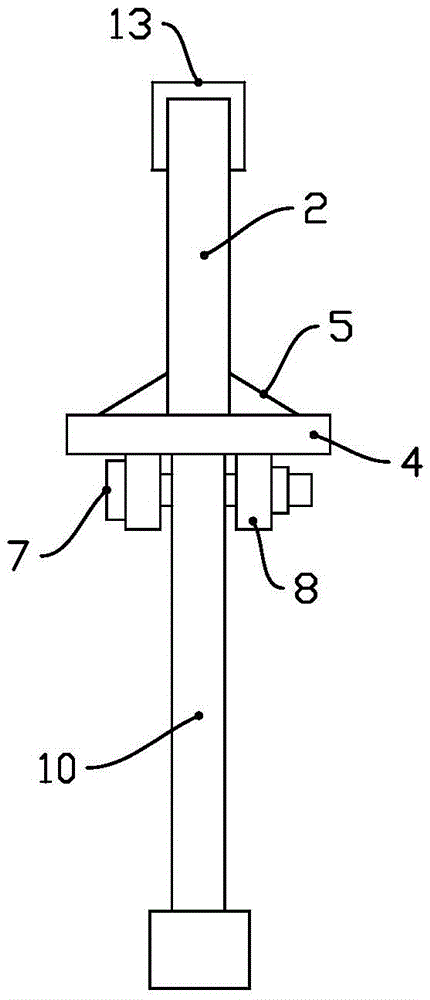

[0018] see Figure 1~2 In an embodiment of the present invention, a wear-resistant and anti-slip lifting device for a crane girder includes a lifting device body 1, a lifting plate 2 is provided on the upper part of the lifting device body 1, and a lifting plate 2 is sleeved at the middle position of the top of the lifting plate 2. Grinding sheath 13, the lifting plate 2 is provided with a lifting hole 3, the lower end of the lifting plate 2 is provided with a connecting plate 4, and the connection between the lifting plate 2 and the connecting plate 4 is provided with a reinforcing plate 5, and the reinforcing plate 5 It is a triangular structure, and the left and right parts of the lower side of the connecting plate 4 are respectively connected with a hook bracket A8 and a hook bracket B9. The hook bracket A8 is connected with a hook A10, the hook A is connected with the hook bracket A8 through a bolt A7, the hook bracket B9 is connected with a hook B11, and the hook B11 is ...

Embodiment 2

[0021] see Figure 1~2 In an embodiment of the present invention, a wear-resistant and anti-slip lifting device for a crane girder includes a lifting device body 1, a lifting plate 2 is provided on the upper part of the lifting device body 1, and a lifting plate 2 is sleeved at the middle position of the top of the lifting plate 2. Grinding sheath 13, the lifting plate 2 is provided with a lifting hole 3, the lower end of the lifting plate 2 is provided with a connecting plate 4, and the connection between the lifting plate 2 and the connecting plate 4 is provided with a reinforcing plate 5, and the reinforcing plate 5 It is a triangular structure, and the left and right parts of the lower side of the connecting plate 4 are respectively connected with a hook bracket A8 and a hook bracket B9. The hook bracket A8 is connected with a hook A10, the hook A is connected with the hook bracket A8 through a bolt A7, the hook bracket B9 is connected with a hook B11, and the hook B11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com