Transportation piling car capable of achieving automatic station-returning charging

A technology of automatic return to the station and stacker trucks, which is applied in the field of handling stacker trucks, and can solve the problems of difficult operators, difficult operations, and difficulty in judging the return direction of stacker trucks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment, content of the invention will be further described:

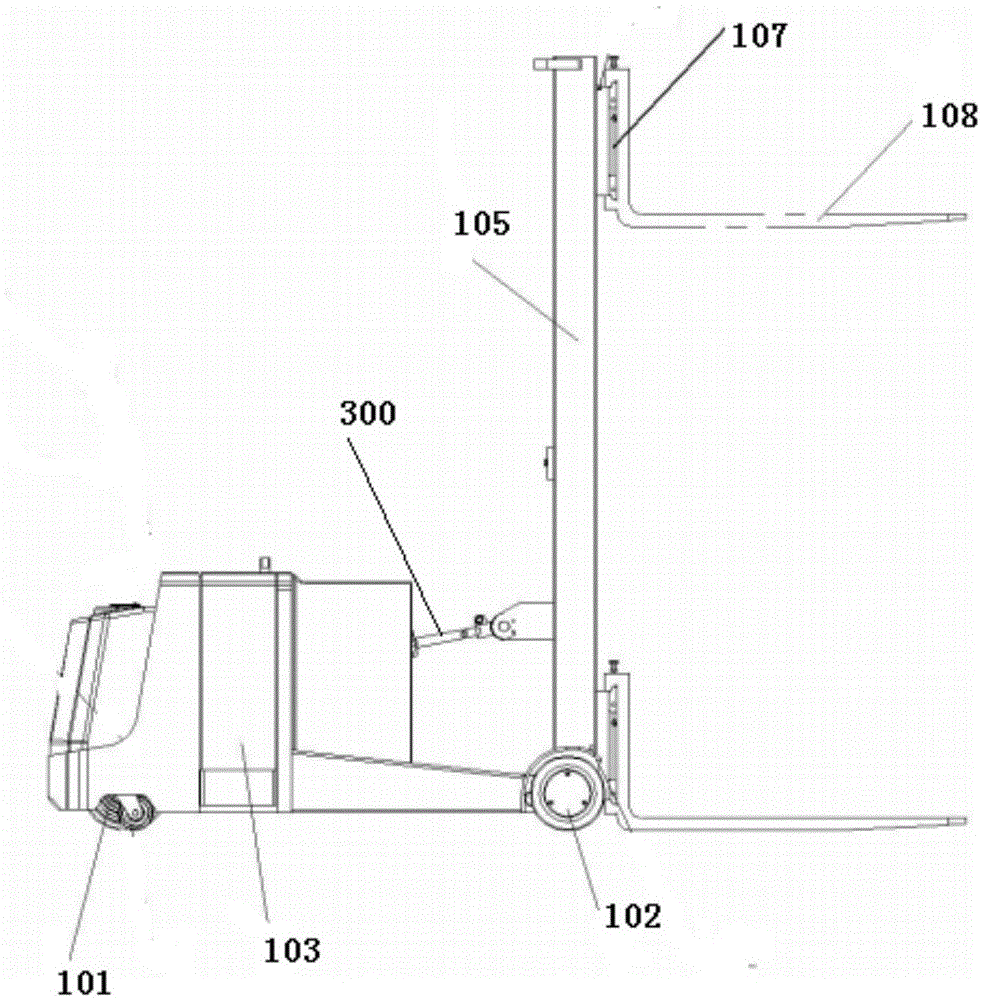

[0026] refer to Figure 1-Figure 12 As shown, the handling and stacking truck that automatically returns to the station for charging includes a vehicle body 103 with drive wheels 101 and load-bearing wheels 102 at the lower end, and a lifting system is provided at the front end of the vehicle body 103. Guide rails are provided on the columns on both sides of the guide rail, a lifting frame 107 is housed on the guiding rails, and a cargo fork 108 is arranged on the front side of the lifting frame 107, and the driving wheel 101 is a universal wheel;

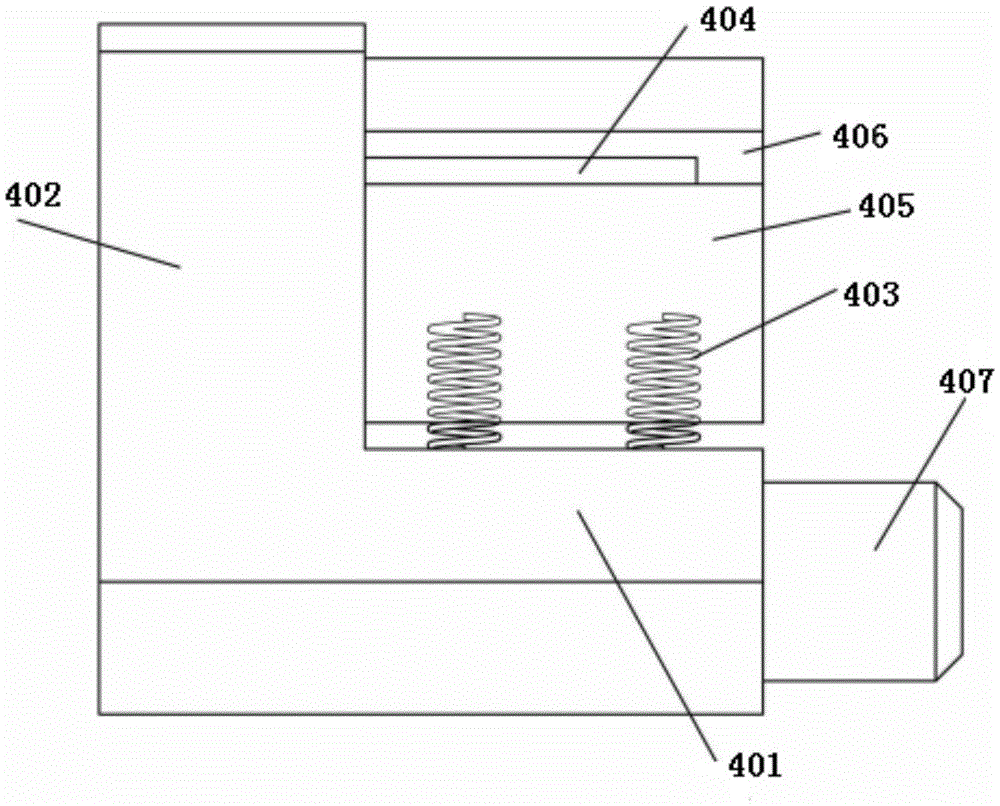

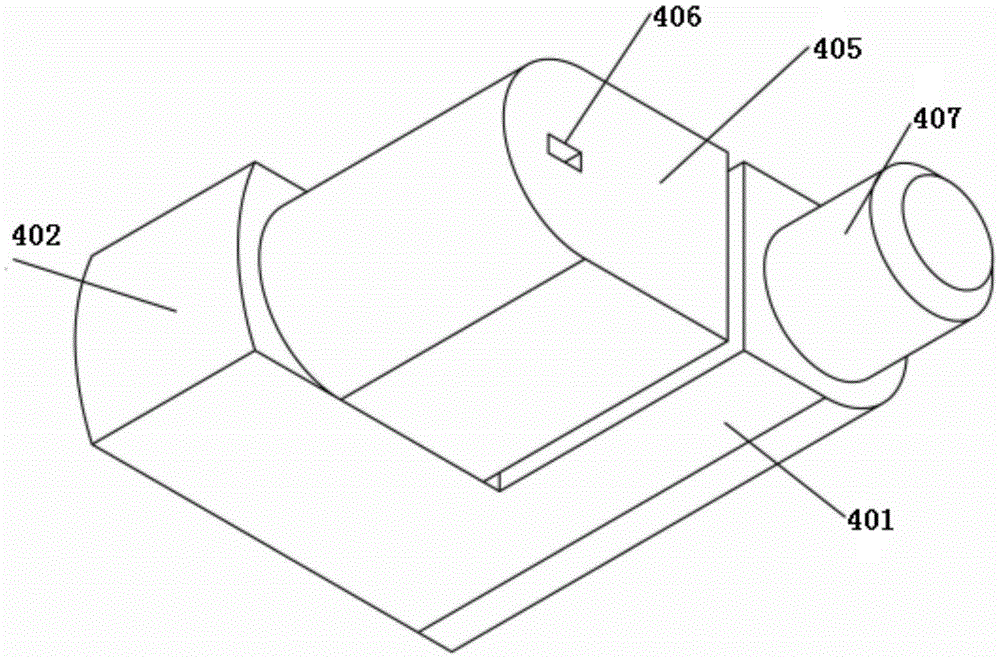

[0027] Also includes the charging system of the handling stacker, the charging system of the handling stacker includes a charging station (charging device) for charging the rechargeable battery equipped with the stacker, figure 2 It is a front view of a charging station in an embodiment. The charging station ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com