A fast locking device for guardrail wire rope

A technology of locking device and steel cable, which is applied in the direction of fences, building structures, stepped structures, etc., can solve the problems of insufficient environmental applicability, insufficient locking force, and low work efficiency, and achieve a wide range of installation applications, locks Sufficient tightening force and high working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

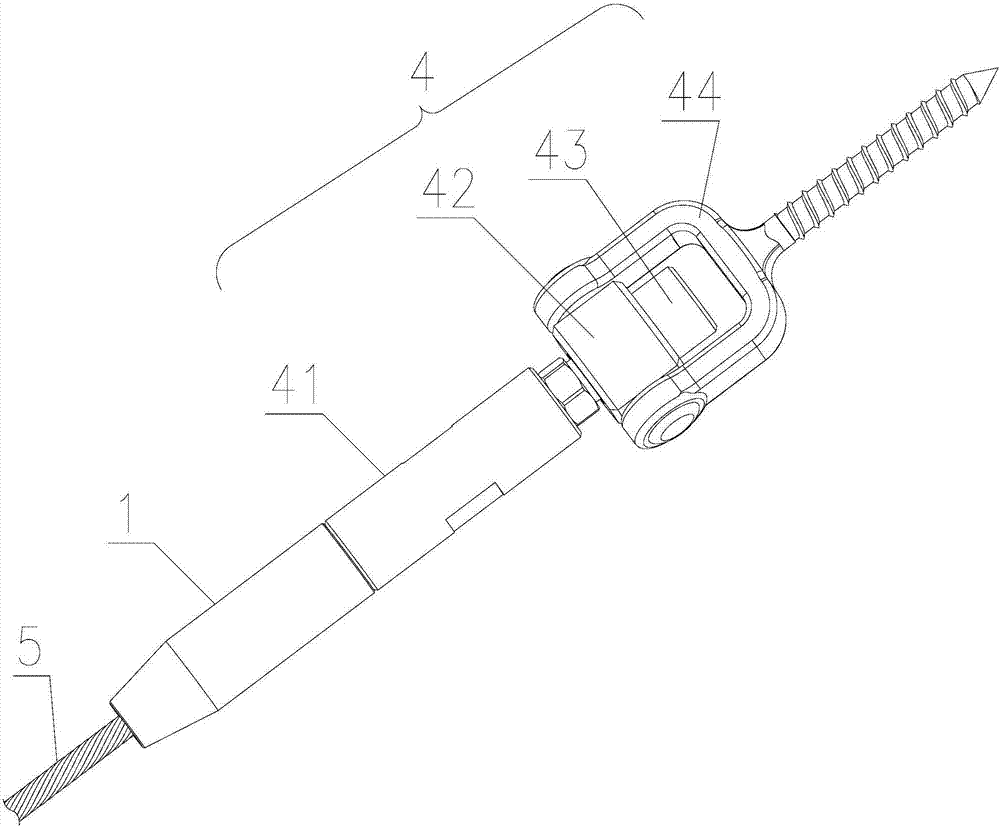

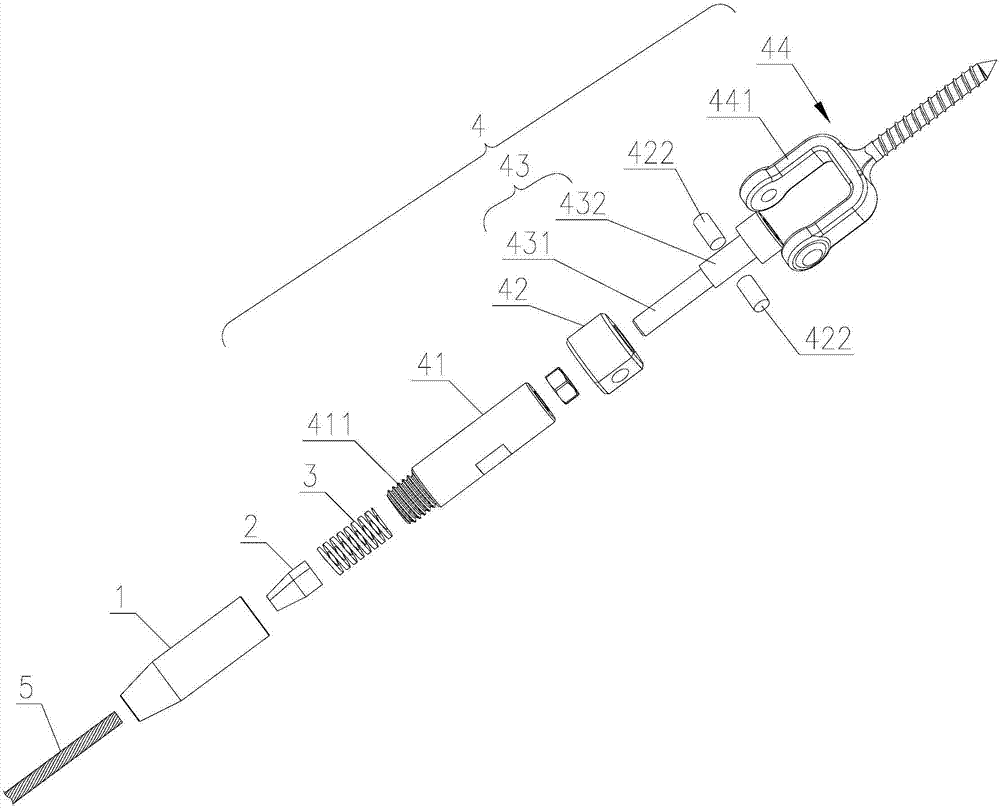

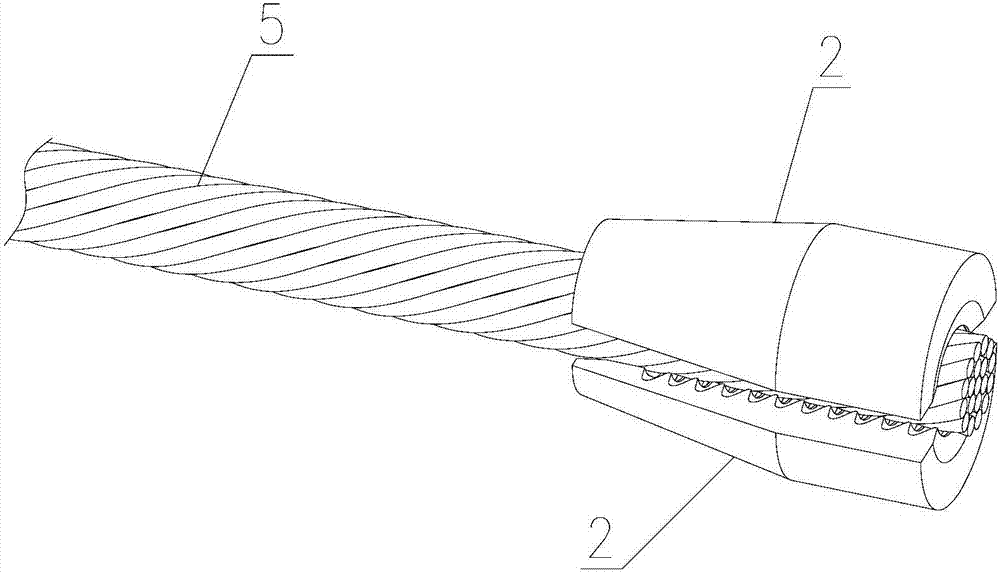

[0064] Such as Figure 1 to Figure 10 As shown, a guardrail cable fast locking device is used to be installed on the steel cable 5 adjacent to its end point and detachably fixed to the guardrail. The guardrail steel cable quick locking device includes: an outer sleeve 1, It has the same tapered through hole 11 and the first internally threaded hole 12, the aperture of the first internally threaded hole 12 is greater than or equal to the maximum aperture of the tapered through hole 11; tapered chuck 2, which has a The clamping hole 21 through which the steel cable 5 passes, and the clamping hole 21 is provided with a plurality of locking teeth 22, which are placed at the tapered through hole 11 of the outer sleeve 1; the elastic element 3, which is placed The bottom of the outer sleeve 1 inner tapered chuck 2; the installation and fixing mechanism 4 is fixedly installed on the guardrail, and the installation and fixing mechanism 4 is provided with a first external threaded rod ...

Embodiment approach 2

[0069] Such as Figure 11 to Figure 13 As shown, the second embodiment is basically the same as the first embodiment, except that the other end of the guardrail fixing member 44 is a screw, and a screw hole is provided on the guardrail, and the screw passes through the screw hole and is fixed on the guardrail with a nut.

Embodiment approach 3

[0071] Such as Figure 14 to Figure 16 As shown, a guardrail cable fast locking device is used to be installed on the steel cable 5 adjacent to its end point and detachably fixed to the guardrail. The guardrail steel cable quick locking device includes: an outer sleeve 1, It has the same tapered through hole 11 and the first internally threaded hole 12, the aperture of the first internally threaded hole 12 is greater than or equal to the maximum aperture of the tapered through hole 11; tapered chuck 2, which has a The clamping hole 21 through which the steel cable 5 passes, and the clamping hole 21 is provided with a plurality of locking teeth 22, which are placed at the tapered through hole 11 of the outer sleeve 1; the elastic element 3, which is placed The bottom of the outer sleeve 1 inner tapered chuck 2; the installation and fixing mechanism 4 is fixedly installed on the guardrail, and the installation and fixing mechanism 4 is provided with a first external threaded rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com