Numerically-controlled vertical rotary working table

A rotary table, CNC vertical technology, used in manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of inability to withstand heavy loads, poor accuracy, etc., to improve bearing capacity, reduce wear, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

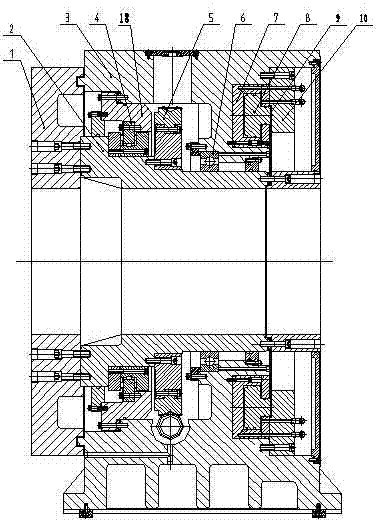

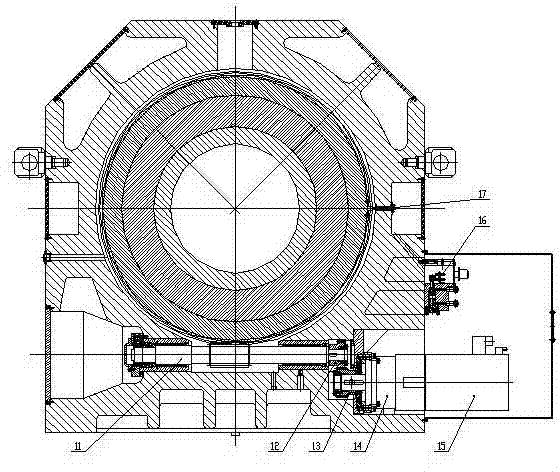

[0011] Attached below figure 1 And attached figure 2 The CNC vertical rotary table of the present invention includes a bed body 3, the servo motor 15 on the bed body 3 is connected with the reducer 14 through screws, the reducer 14 is connected with the gear 13, the gear 13 meshes with the gear 12, and the gear 12 The worm 11 is fixed on the top, and the worm 11 meshes with the worm wheel 5. The inner hole of the bed body 3 is provided with a main shaft 2. One end of the main shaft 2 is fixed with a worktable 1. The worm wheel 5 is fixedly installed on the main shaft 2. One side of the worm wheel 5, the main shaft A ball bearing 6 is provided between 2 and the bed body 3, and the ball bearing 6 is used as an auxiliary support. A transition sleeve 18 is fixed on the bed body 3 on the other side of the worm gear 5, and a combined bearing 4 is provided between the main shaft 2 and the transition sleeve 18. , combined bearing 4 is used as the main support, the bearing itself is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com