Double-layer parking device with lifting transverse-movement mechanism

A double-deck parking, lift and traverse technology, applied in the direction of the building, building type, building, etc. where the car is parked, can solve the problem of inability to wait, and achieve the effect of low cost, easy implementation, and simple electromechanical system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

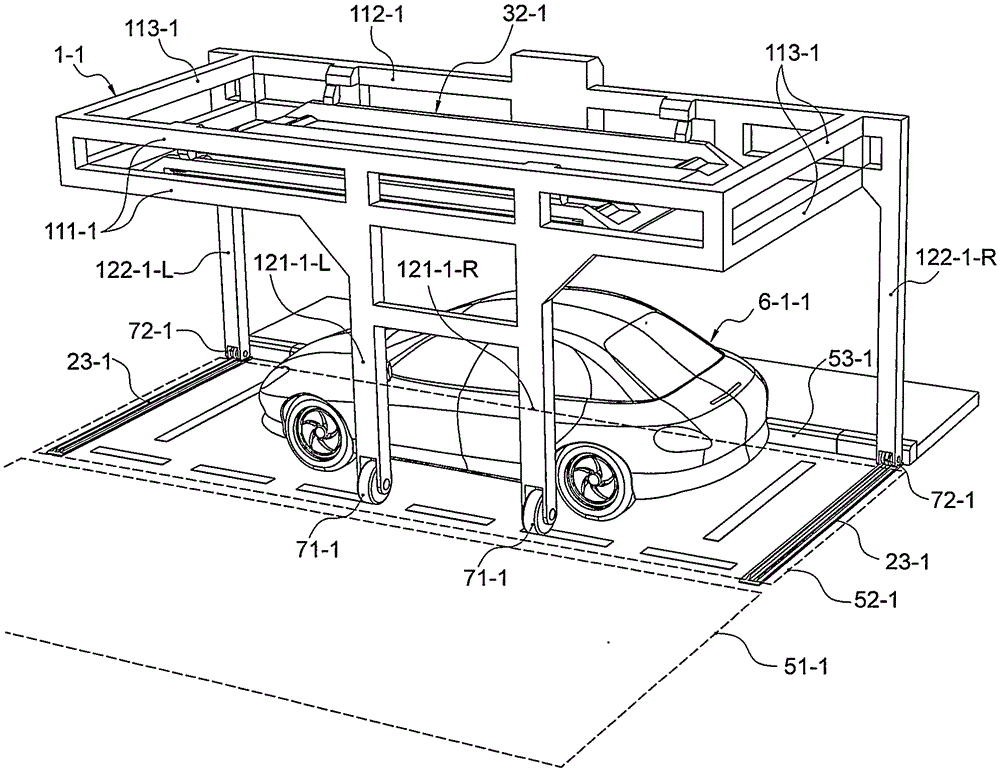

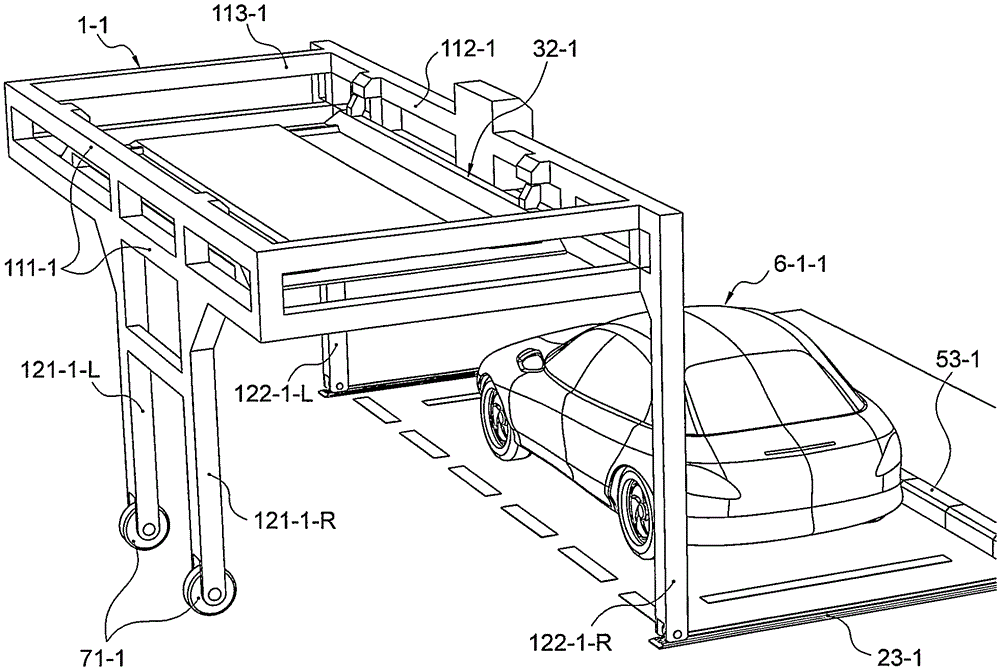

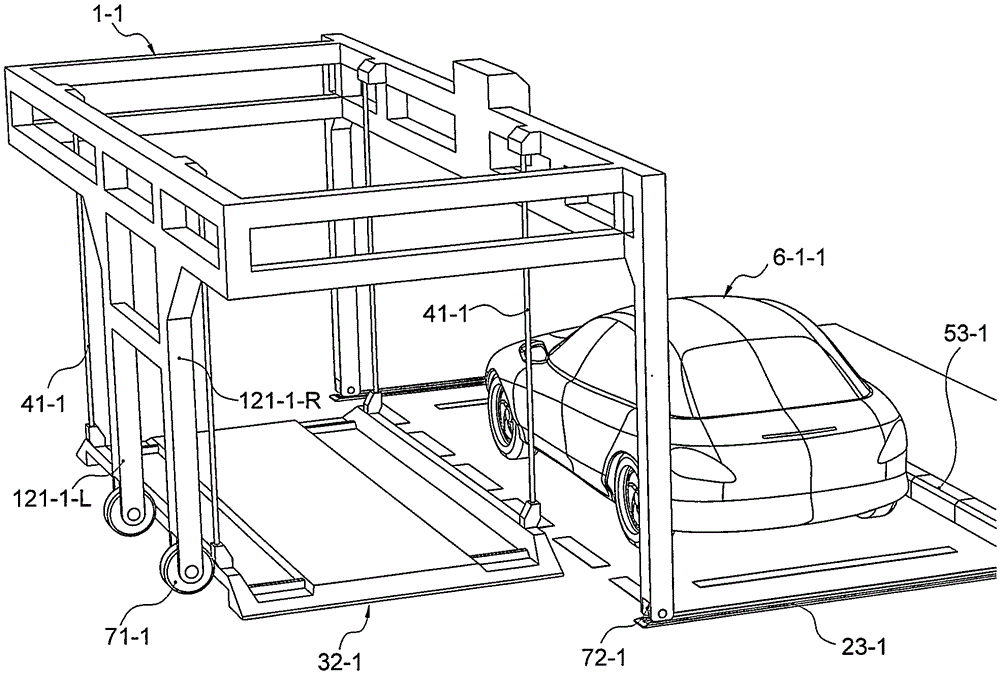

[0074] Example 1 as Figure 1-7 shown. This is a kind of double-deck parking equipment with two forward parking spaces up and down installed above the vehicle parking area 52-1 which accounts for about one forward parking space. Traversing frame 1-1 has left and right two front outriggers 121-1-L, 121-1-R with bottom wheel 71-1 and left and right two rear outriggers 122-1-L with bottom wheel 72-1 , 122-1-R. The rear outrigger bottom wheel 72-1 runs on the left and right two tracks 23-1 on the ground. By means of the above-mentioned outrigger bottom wheels, the traversing frame 1-1 positioned at the vehicle parking area 52-1 can go straight forward to the vehicle access area 51-1 according to the above-mentioned track 23-1 (see figure 2 ).

[0075] The tops of the left and right front outriggers 121-1-L, 121-1-R, left and right rear outriggers 122-1-L, 122-1-R of the traverse frame 1-1 are formed by the front main beam 111-1, the left and right sides The main girder 113-1...

Embodiment 2

[0081] Example 2 as Figure 8 to Figure 16 shown. see Figure 8 , which is a kind of double-deck parking equipment with two horizontal parking spaces up and down above the vehicle parking area 52-2 that accounts for one horizontal parking space.

[0082] The front end of the traverse frame 1-2 has two left and right front legs 121-2-L, 121-2-R with bottom wheels 71-2 and two left and right rear legs 122-2- with bottom wheels 72-2. L, 122-2-R. The rear outrigger bottom wheel 72-2 runs on the left and right two tracks 23-2 on the ground on both sides of the vehicle parking area 52-2. By means of the bottom wheels of above-mentioned outriggers, the traversing frame 1-2 positioned at the vehicle parking area 52-2 can go straight ahead to the vehicle access area 51-2 according to the above-mentioned track 23-2 (see Figure 9 , Figure 10 ).

[0083] The upper ends of the left and right front outriggers 121-2-L, 121-2-R, left and right rear outriggers 122-2-L, 122-2-R of the t...

Embodiment 3

[0096] Example 3 as Figure 17 to Figure 22 shown. see Figure 17 , Figure 18 , which is a kind of double-deck parking equipment with two horizontal parking spaces up and down that is installed overhead and above the vehicle parking area 52-3 that accounts for one horizontal parking space.

[0097] Traversing frame 1-3 has left and right two front legs 121-3-L, 121-3-R with bottom wheel 71-3 and left and right two rear legs 122-3-L with bottom wheel 72-3 , 122-3-R. The rear outrigger bottom wheel 72-3 runs on the left and right two tracks 23-3 on the ground. By means of the bottom wheels of above-mentioned outriggers, the traversing frame 1-3 positioned at the vehicle parking area 52-3 can go straight forward to the vehicle access area 51-3 according to the above-mentioned track 23-3 (see Figure 18 , Figure 19 ).

[0098] The upper ends of the left and right front outriggers 121-3-L, 121-3-R, left and right rear outriggers 122-3-L, 122-3-R of the traverse frame 1-3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com