A ball screw with adjustable preload structure

A technology of ball screw and pre-tightening force, which is applied to belts/chains/gears, mechanical equipment, transmission devices, etc., which can solve problems such as increased wear, serious loss of ball screw pre-tightening force, and reduced efficiency, and achieve work The effect of stable state, improved adjustment efficiency and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

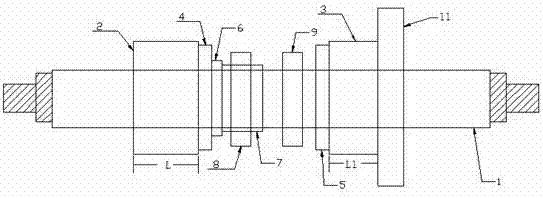

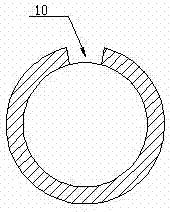

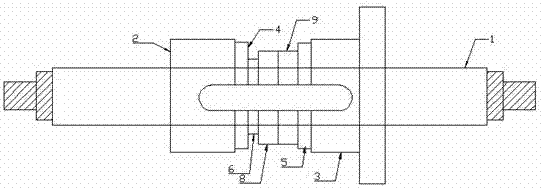

[0019] like figure 1 A ball screw with an adjustable pre-tightening structure is shown, which consists of a ball screw 1 (not marked in the thread diagram), and a first screw nut 2 and a second screw arranged on the ball screw 1. The screw nut 3, and the connecting flange 11 arranged on the ball screw 1 and connected to the side of the second screw nut 3, and the pre-tensioner arranged between the first screw nut 2 and the second screw nut 3 The force adjustment assembly is composed of; the pretightening force adjustment assembly includes an adjustment ring 4 connected with the first lead screw nut 2, a positioning protrusion 6 connected with the adjustment ring 4, and a threaded rotating sleeve 7 connected with the positioning protrusion 6 ( not marked in the thread diagram), and the first adjusting ring 8 that is arranged on the threaded rotating sleeve 7 and used in conjunction with the threaded rotating sleeve 7, and the limit ring 5 connected with the second lead screw nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com