Resistance reduction-propulsion integrated structure of manually-ventilated supercavitating torpedo

A supercavitation and torpedo technology, applied to torpedoes, self-propelled bombs, sea torpedoes, etc., can solve the problems of deviation from the channel, torpedo loss of stability and maneuverability, etc., and achieve the effect of stable motion form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in more detail below in conjunction with accompanying drawing example:

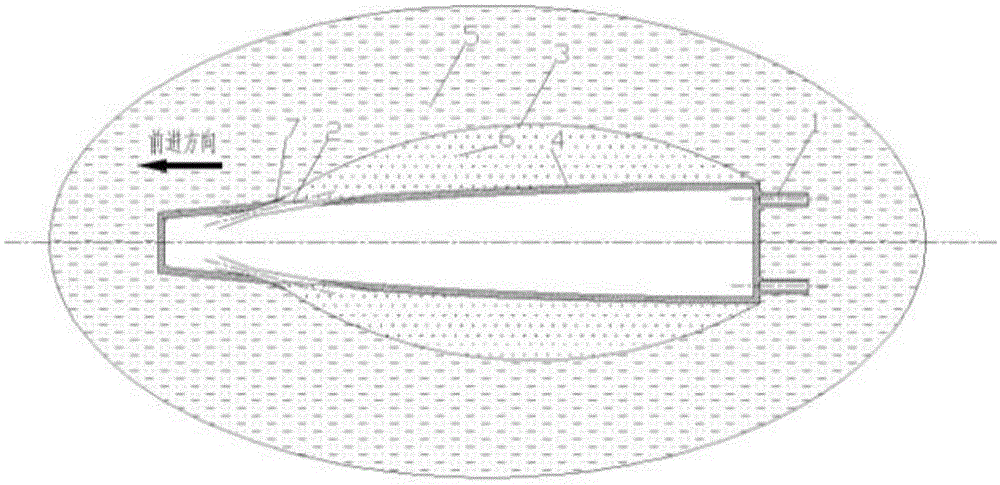

[0014] combine figure 1 , the drag reduction-propulsion integrated configuration of an artificially ventilated supercavitation torpedo of the present invention, the torpedo is immersed in the liquid 5 to run, and there is a starting rocket 1 at the tail of the torpedo body, and the head is a blunt cavitation generator, There are four nozzles 2 at the front end of the mine body, and there are eaves 7 extending two centimeters at the front edge of the nozzle outlet.

[0015] The four nozzles are evenly distributed in the four directions of up, down, left, and right.

[0016] The axial position of the nozzle is at 1 / 5 of the total torpedo.

[0017] The nozzle type is oblique nozzle, and the angle formed by the central axis of the nozzle and the central axis of the torpedo is 10°-15°.

[0018] The protruding eaves are a ring structure around the mine body.

[0019...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com