Tool for detecting location degree of workpiece hole

A technology of position degree and workpiece hole, which is applied in the direction of measuring device, mechanical measuring device, and mechanical device, can solve the problems of affecting the detection efficiency and quality of parts, affecting the assembly requirements of parts, and the detection accuracy is not high, so as to ensure the detection efficiency And the effect of testing quality, improving production efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict.

[0020] Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

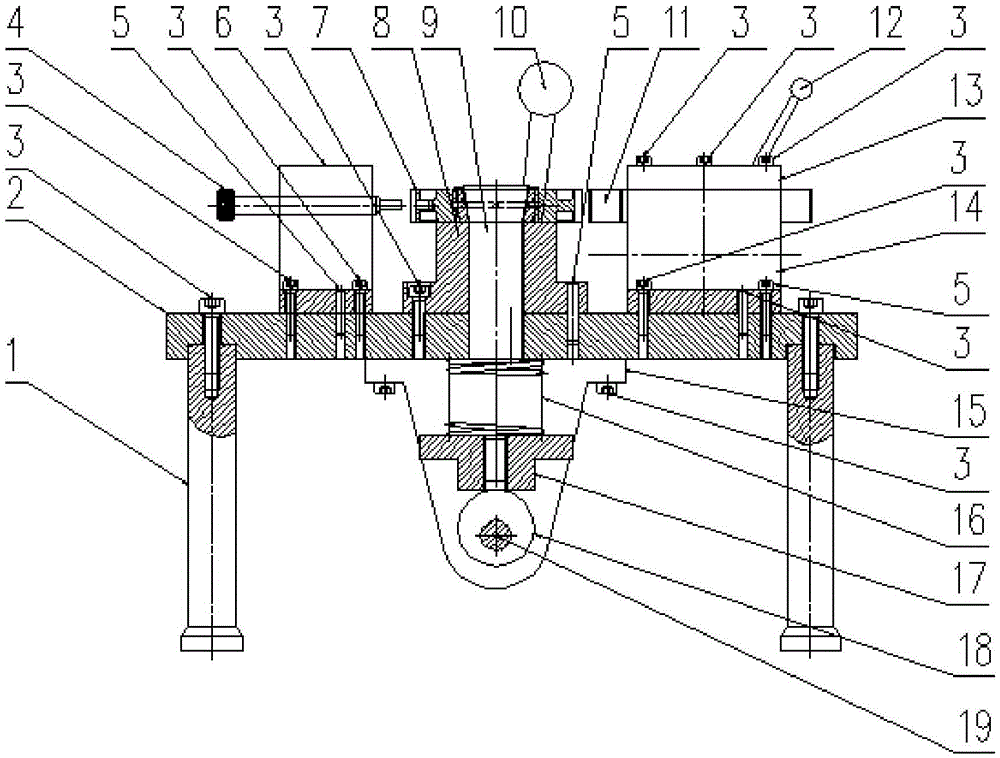

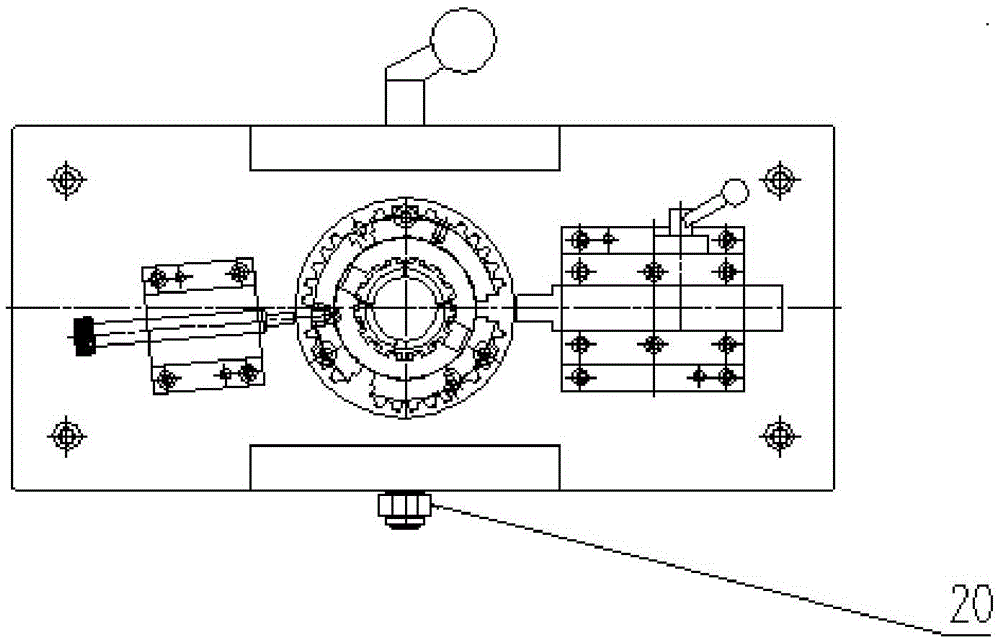

[0021] A checking tool for detecting the position of a workpiece hole, comprising a first guide seat 6, a second guide seat 14 and a locking device fixed on a base 2. The first guide seat 6 and the second guide seat 14 are respectively fixed on On both sides of the base 2, the locking device is located between the first guide seat 6 and the second guide seat 14. The first guide seat 6 is provided with a detection pin 4 in clearance fit; the second guide seat 14 The upper clearance fit is provided with positioning pins 11.

[0022] The locking device includes an expansion sleeve 8, a pull rod 9, a first handle 10, and an eccentric wheel 29. The expansion sleeve 8 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com