Vibrating gyroscope based on one-piece cylindrical shell quartz resonator and piezoelectric film

A cylindrical shell, piezoelectric film technology, applied in the direction of gyro effect for speed measurement, gyroscope/steering sensing equipment, measurement device, etc. and other problems, to achieve the effect of low power consumption, low processing cost, and reduction of anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

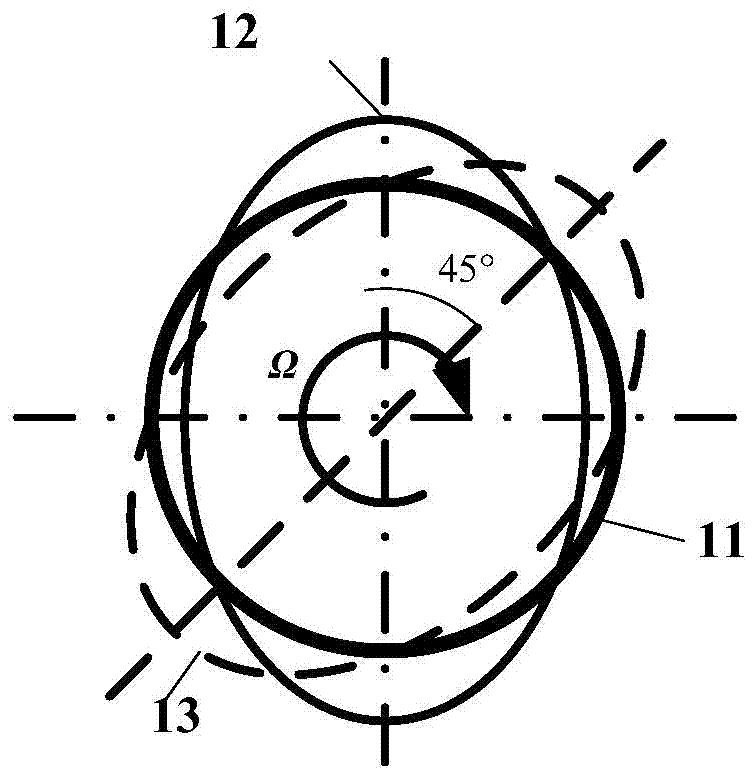

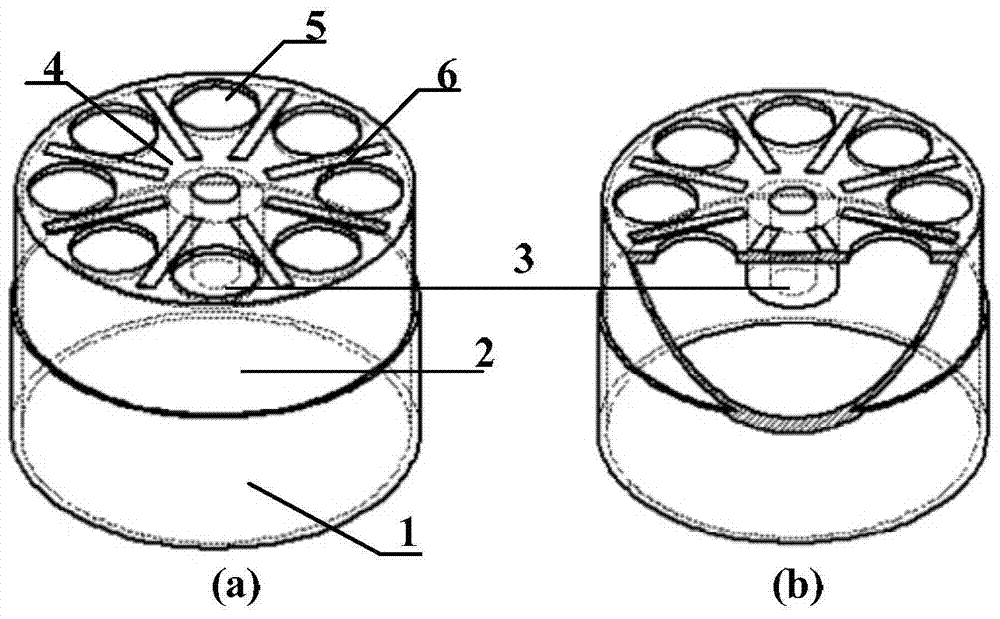

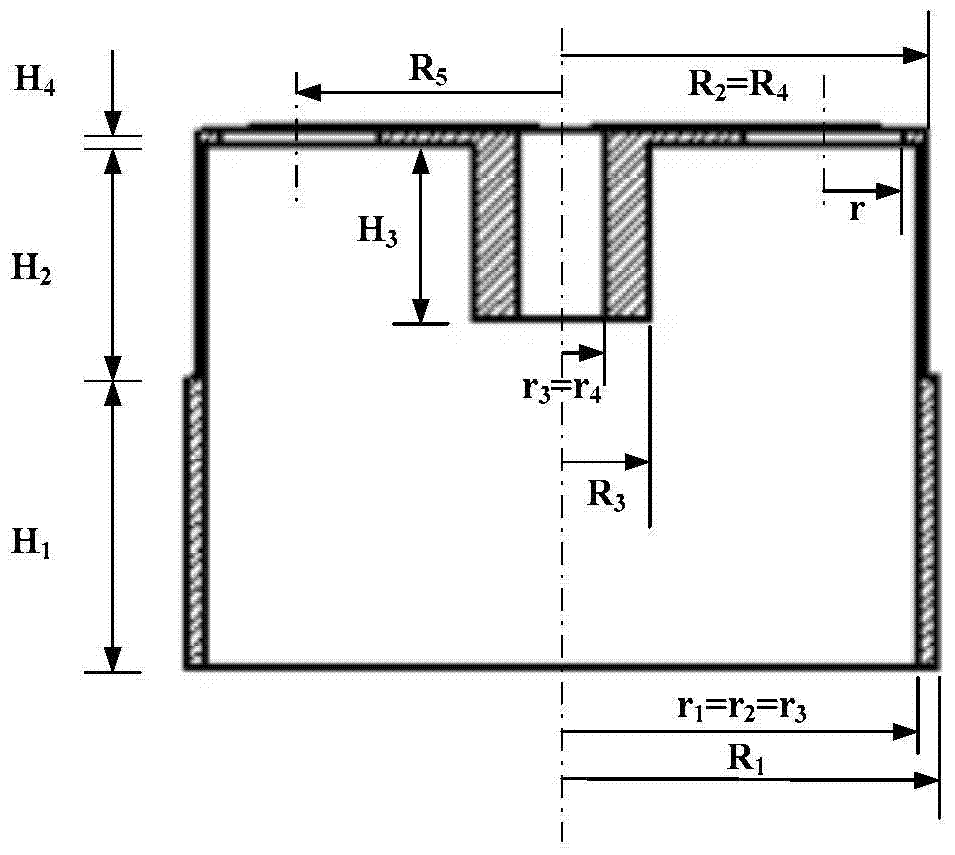

[0034] The resonator of the vibrating gyroscope with a cylindrical shell in this embodiment is made of high-purity fused silica material, and the internal loss of the material is extremely small and has excellent isotropy, so that the high quality factor and physical symmetry of the resonator can be guaranteed. Therefore, the characteristics of high sensitivity, high signal-to-noise ratio, low drift error and low power consumption of the cylindrical shell vibrating gyroscope are guaranteed. Such as figure 2 , image 3 As shown, the cylindrical shell gyroscope of this embodiment includes a resonant ring 1, a vibration guide ring 2, a fixed column 3, a chassis 4, and a piezoelectric thin film electrode 6, and the chassis 4 is provided with 8 chassis holes 5.

[0035] The resonance ring 1 and the vibration guide ring 2 are both cylindrical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com