Thermal infrared imager variable power in-place mechanism and thermal infrared imager

An infrared thermal imager and position-limiting technology, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of difficult zoom control, large space occupation, and low efficiency, and achieve convenient and quick adjustment, convenient operation, and continuous Adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

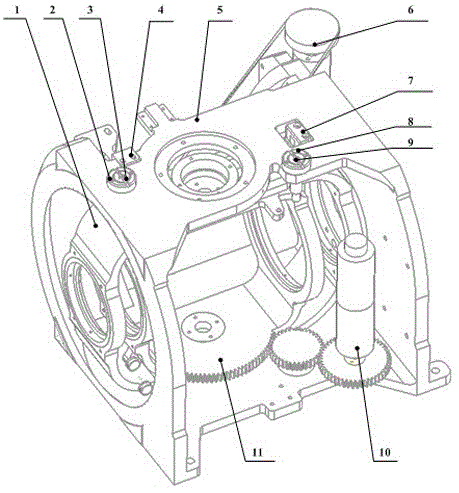

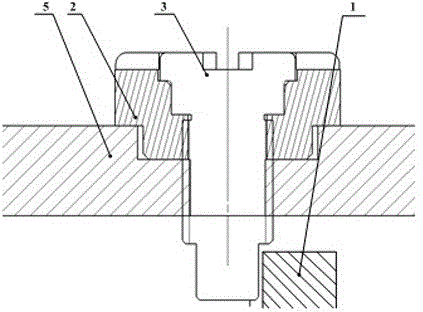

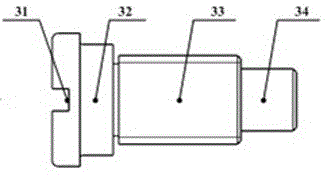

[0024] The thermal imaging camera in Embodiment 1 of the present invention is a thermal imaging camera with three fields of view, and the thermal imaging camera has a small field of view, a middle field of view and a large field of view. Such as Figure 1 to Figure 7 As shown, the infrared thermal imager includes a variable magnification in place mechanism, and the magnification in place mechanism includes a base 5 and a field of view variable magnification frame that is located in the base and can be screwed in and out of the base along the front and rear directions. There are two groups of magnification frames, which are the large field of view zoom frame 1 and the medium field of view zoom frame 11. The large field of view zoom frame 1 is connected to the large field of view driving element 6, and the large field of view driving element 6 can drive the large field of view. The zoom frame is screwed into and out of the base; the middle field of view zoom frame 11 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com