Spoke air hole double-hole processing mold and processing method thereof

A hole processing and spoke technology, which is applied in the spoke air hole double-hole processing mold and its processing field, can solve the problems of affecting the positioning performance of the middle hole, low efficiency, and large impact of the middle hole of the spoke, and achieve the effect of reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below through specific embodiments and related drawings.

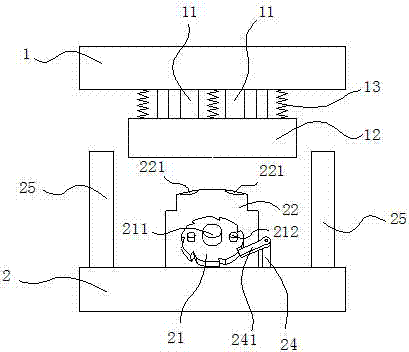

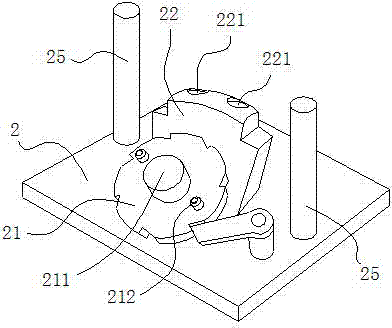

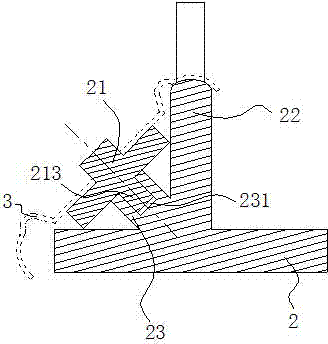

[0030] Such as Figure 1~8 As shown, a spoke air hole double-hole processing mold includes a stamping machine upper die 1 and a lower die 2 for obliquely installing the spokes 3. Ratchet 21, the rear side of the ratchet 21 is provided with a punching projection 22 that matches the bottom surface of the arc-shaped edge of the spoke 3, two punches 11 are provided below the upper die 1, and the upper end surface of the punching projection 22 is Two counterbores 221 are provided to facilitate the downward cooperation of the punch 11. By rotating the ratchet 21, the punch 11 punches out evenly distributed air holes 33 on the arc edge of the spoke 3.

[0031] In this embodiment, the upper end surface of the ratchet 21 is provided with a convex pin 211 matched with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com