Electric appliance mold box mounting structure

A technology of installation structure and mold box, which is applied in the direction of supporting machines, connecting components, electrical components, etc., can solve the problems of difficult disassembly and assembly by maintenance personnel or users, increased labor intensity of maintenance personnel, and decreased user experience of users, etc., to achieve convenience Disassembly, improve stability, avoid interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

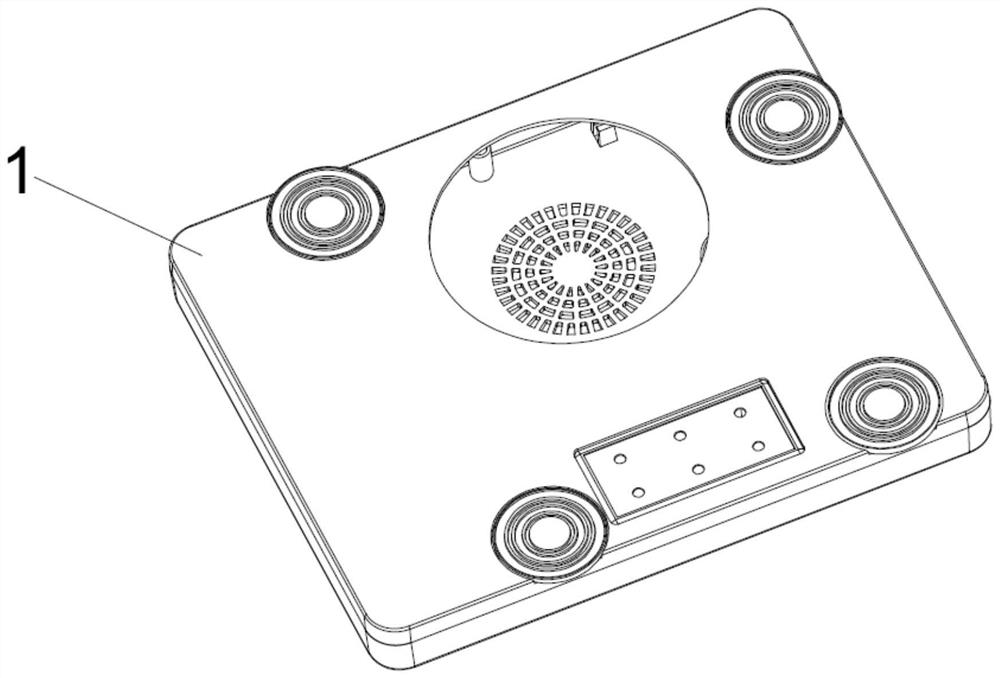

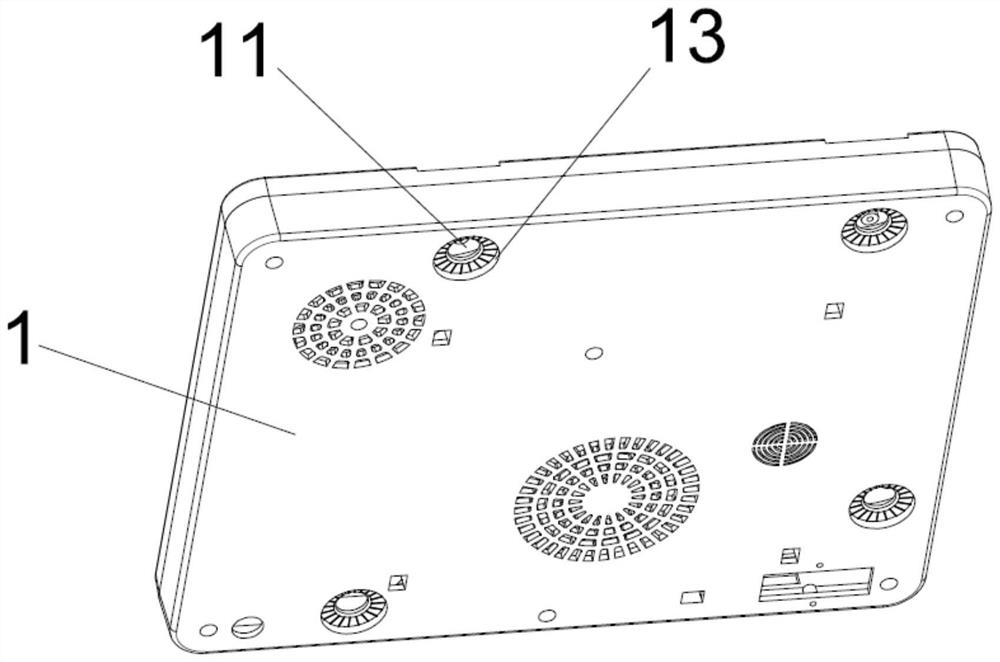

[0045] see figure 1 , image 3 , Figure 6~Figure 8 .

[0046] An electrical module box installation structure is provided for realizing the connection between the electrical module box body 1 and the panel 4, the installation structure passes through the electrical module box body 1, and the panel 4 can be directly operated on the surface of the panel 4 on the electrical module box body 1 The panel of touch screen, as glass panel etc.; The corresponding position of the touch screen is provided with an operation hole.

[0047] The installation structure includes mushroom nails, the top of the mushroom nails is fixedly connected to the panel 4, and the installation structure also includes a locking support that can cooperate with the mushroom nails to lock the electrical module box;

[0048] When the locking support is separated from the mushroom nail, the electrical module box body 1 is separated from the mushroom nail;

[0049] When the locking support is locked with the...

Embodiment 2

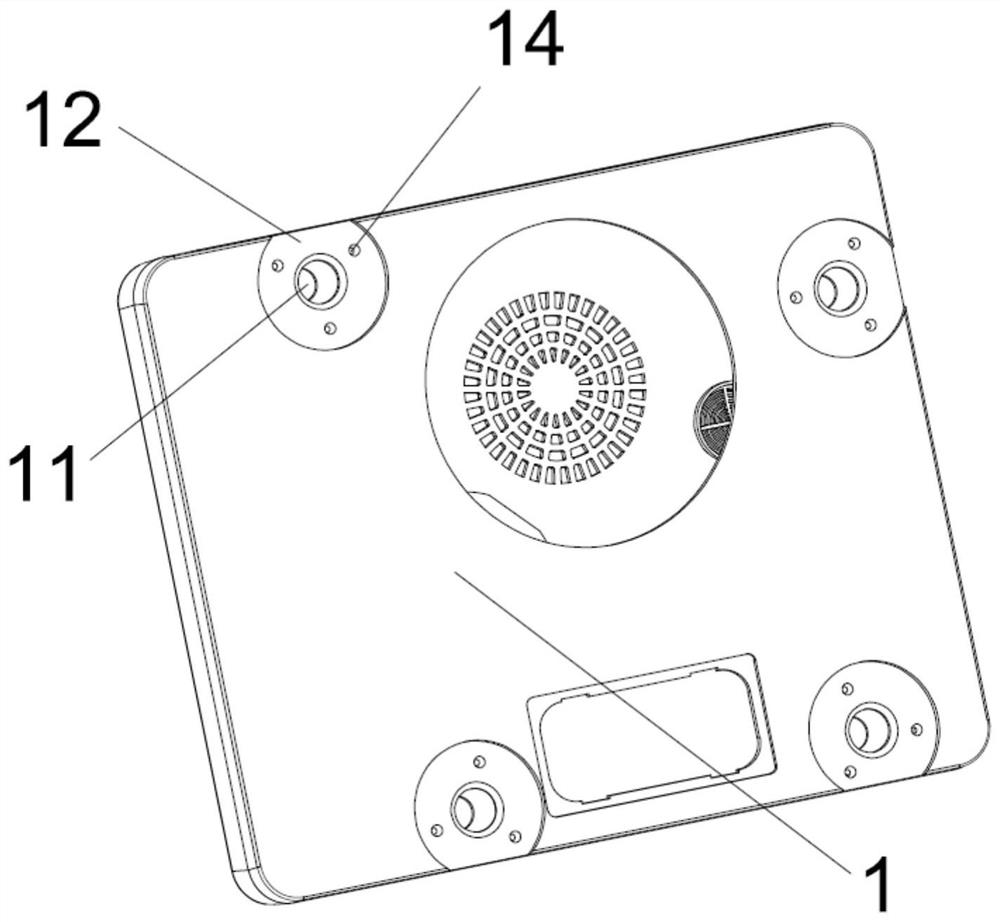

[0068] see Figure 1~5 , Figure 7 , Figure 9 and Figure 10 .

[0069] The arrangement of mushroom nails and locking support members in Embodiment 1 will cause the following problems:

[0070] In order to ensure the disassembly and assembly of the electrical module body 1 of different sizes, that is, the thickness, the second stud 61 needs to reserve a longer length. When there are some parts that need to move relative to the electrical module body 1 in the use area (such as Drawers, etc.), the second stud 61 and the locking support located outside the electrical module body 1 will interfere with the relative moving parts, making the installation structure unable to adapt to the use area, that is, the applicability of the installation structure will be subject to special use area impact.

[0071] The difference from Example 1 is:

[0072] The mushroom nail includes a mushroom head 21 connected to the panel 4 and a mushroom rod 22 located inside the electrical module bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com