Thermal protection performance tester

A tester and heat protection technology, which is applied in the field of heat protection performance testers, can solve the problems of single detection by the detection device, uneven temperature in the heating area, difficulty in temperature controllability, etc., and achieve comprehensive measurement, controllable temperature rise and The effect of expanding the applicable measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

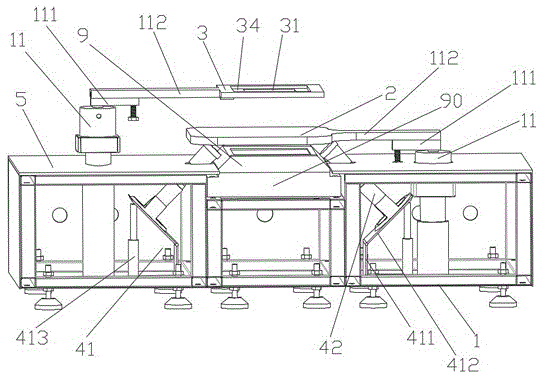

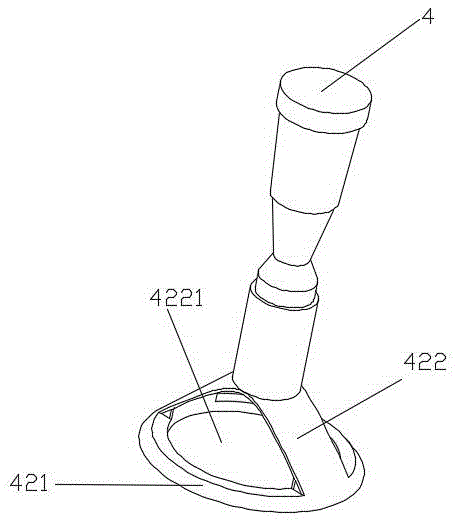

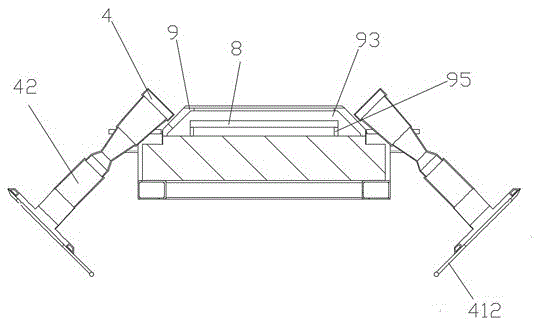

[0029] A heat protection performance tester, comprising a frame 1, a heating device arranged on the frame, a heat insulation protection plate 2 above the heating device, a sample holder plate 3 above the heat insulation protection plate, the heat insulation protection The plate and the sample holder plate are rotatably or translatably arranged on the frame, the center of the sample holder plate has a sample fire through hole 31, the area of the heat insulation protection plate is larger than the area of the sample holder plate, and the The heating device includes a fire head 4 arranged toward the direction of the sample fire passage, and a heat dissipation device is arranged in the heat insulation protection plate.

[0030] An adiabatic pressure-sensitive plate 6 for pressing the sample and sensing the temperature of the sample is arranged on the sample rack, a temperature-sensitive component is arranged on the adiabatic protection plate, and a heat-sensitive part is arrang...

Embodiment 2

[0039] The difference from the above-mentioned embodiment is that the inclined elevating frame includes a frame 411 and a mounting plate 412 whose lower end is hinged on the frame for adjusting the angle of the burner, and the seat tube of the burner is vertically arranged on the mounting plate. An adjustment oil cylinder 413 for adjusting the angle of the mounting plate is provided on the stand, and the heat insulation protection plate and the sample rack plate are respectively connected with a rotating oil cylinder 11, and the bottom of the rotating oil cylinder is connected with a lifting oil cylinder.

[0040] The adiabatic pressure-sensitive plate is also provided with a laser sensor for detecting whether the sample is burnt through, and a master control device is provided on one side of the frame. The laser sensor, temperature controller, rotating cylinder, lifting cylinder and adjusting cylinder Electrically connected with the master control device.

Embodiment 3

[0042] The difference from the above embodiment is that the side of the frame is also provided with a protective cover, the protective cover is provided with cooling holes, the rotating oil cylinder is provided with a rotary connection block 111, the heat insulation protective plate and The sample holder plate is connected to the rotary oil cylinder through the connecting arm 112 detachably connected with the rotary connection block, and the sample holder plate includes a bottom support plate 32 and a hollow sample pressing frame 33 hinged on the bottom support plate, so The inner wall of the hollow pressure sample frame is the wall of the sample placement groove, and the bottom surface of the hollow pressure sample frame is lower than the bottom surface 311 of the sample placement groove, and the inner wall of the hollow pressure sample frame is lower than the sample placement groove. The bottom surface of the placement tank forms a compression section 331, and the upper surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com