Terminal equipment type bottom cover plate assembling structure and application method thereof

A technology of terminal equipment and assembly structure, which is applied in the field of bottom cover assembly structure of terminal equipment, can solve the problems of poor connection strength, large gap and unsightly appearance, and achieves the effects of long service life, convenient operation and reliable installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

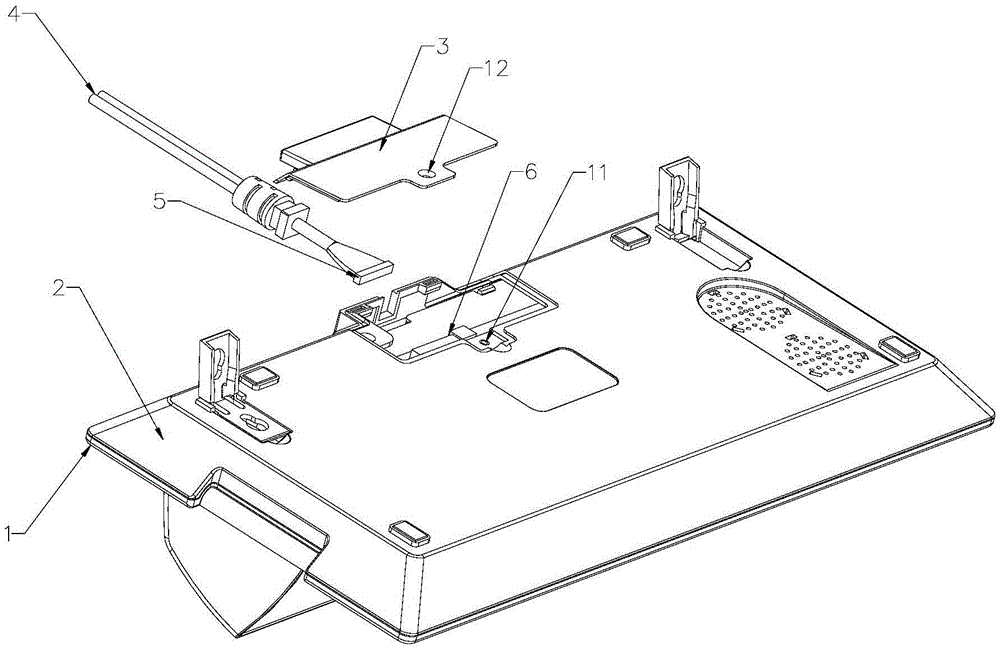

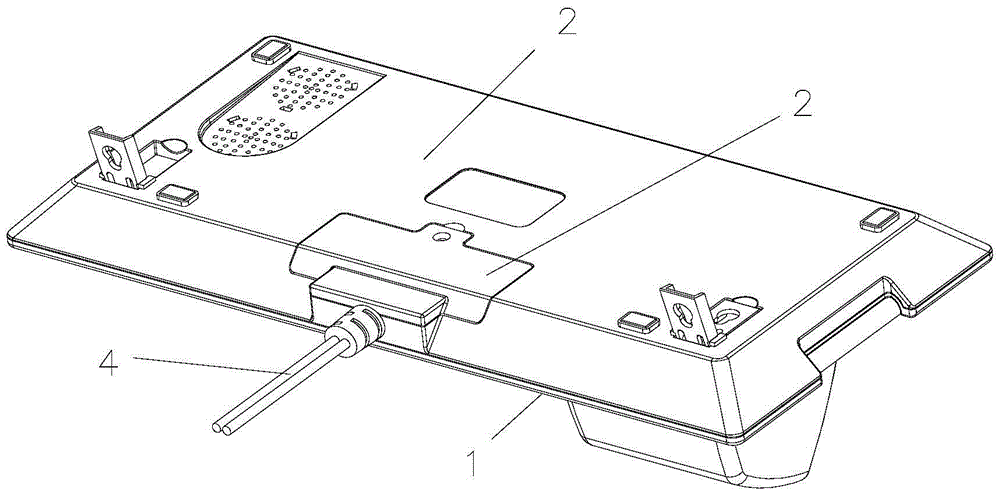

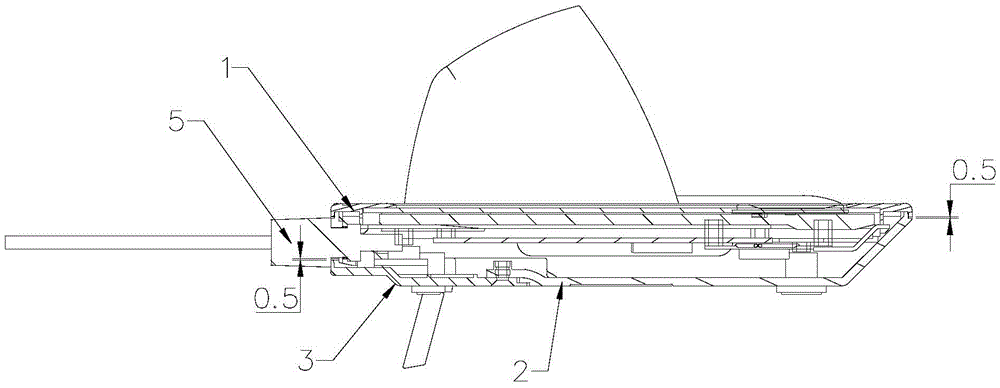

[0033] see figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , The upper cover 1 of the interactive terminal and the lower cover 2 of the interactive terminal are fixed with buckles and then tightened with screws. The cable 4 is fixed on the outside of the bank counter, and the connector 5 of the cable 4 is inserted into the socket 6 of the main board, and the socket 6 of the main board is arranged on the inner side of the lower cover 2 of the interactive terminal. The outer side of the interactive terminal lower cover 2 is provided with a lower cover rib position 10, the interactive terminal lower cover 2 is provided with an interactive terminal lower cover button position 9 near the outer side, and the inner side of the interactive terminal lower cover 2 away from the lower cover rib position 10 is provided with There is a first screw hole 11, the rear end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com