Direct-current charging gun mechanism and method for monitoring connection reliability of direct-current charging gun mechanism

A DC charging and reliability technology, used in environmental/reliability testing, connection, charging stations, etc., can solve the problem of inability to accurately judge the qualification of the charging socket of the charging gun, and achieve the effect of avoiding overheating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

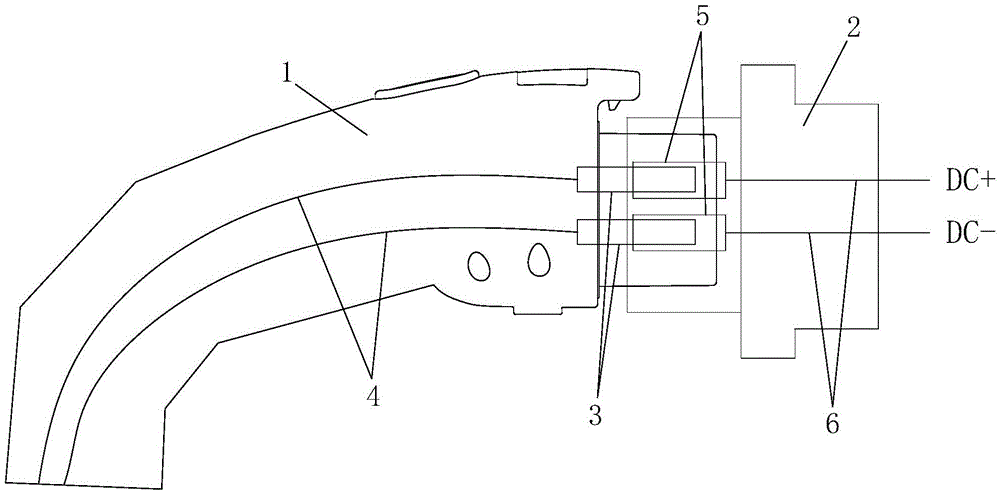

[0015] Such as figure 1 As shown, a DC charging gun mechanism includes a charging gun head 1 and a charging socket 2 detachably connected to the charging gun head; one end of the charging gun head is provided with a conductive metal pin 3 of the charging gun head, and There is a charging gun head conductive cable 4 connected to the charging gun head conductive metal male pin; one end of the charging socket is provided with a charging socket conductive metal female pin 5 that matches the charging gun head conductive metal male pin, and the charging socket A charging socket conductive cable 6 connected to the charging socket conductive metal female pin is provided inside.

[0016] It is worth noting that there are two conductive metal male pins of the charging gun head and two conductive metal female pins of the charging socket. However the wires should be nine, figure 1 Only two wires (DC+ and DC-) used to transmit DC fast charging current are drawn in the figure, and the rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com