A tool automatic identification system and a tool automatic identification method of a numerical control machining center based on RFID

A technology of automatic identification system and machining center, applied in the direction of cooperating devices, instruments, computer parts, etc., can solve the problems of affecting efficiency, low efficiency, opaque tool data, etc., to increase the number of tool management and reduce production costs , the effect of convenient enterprise management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

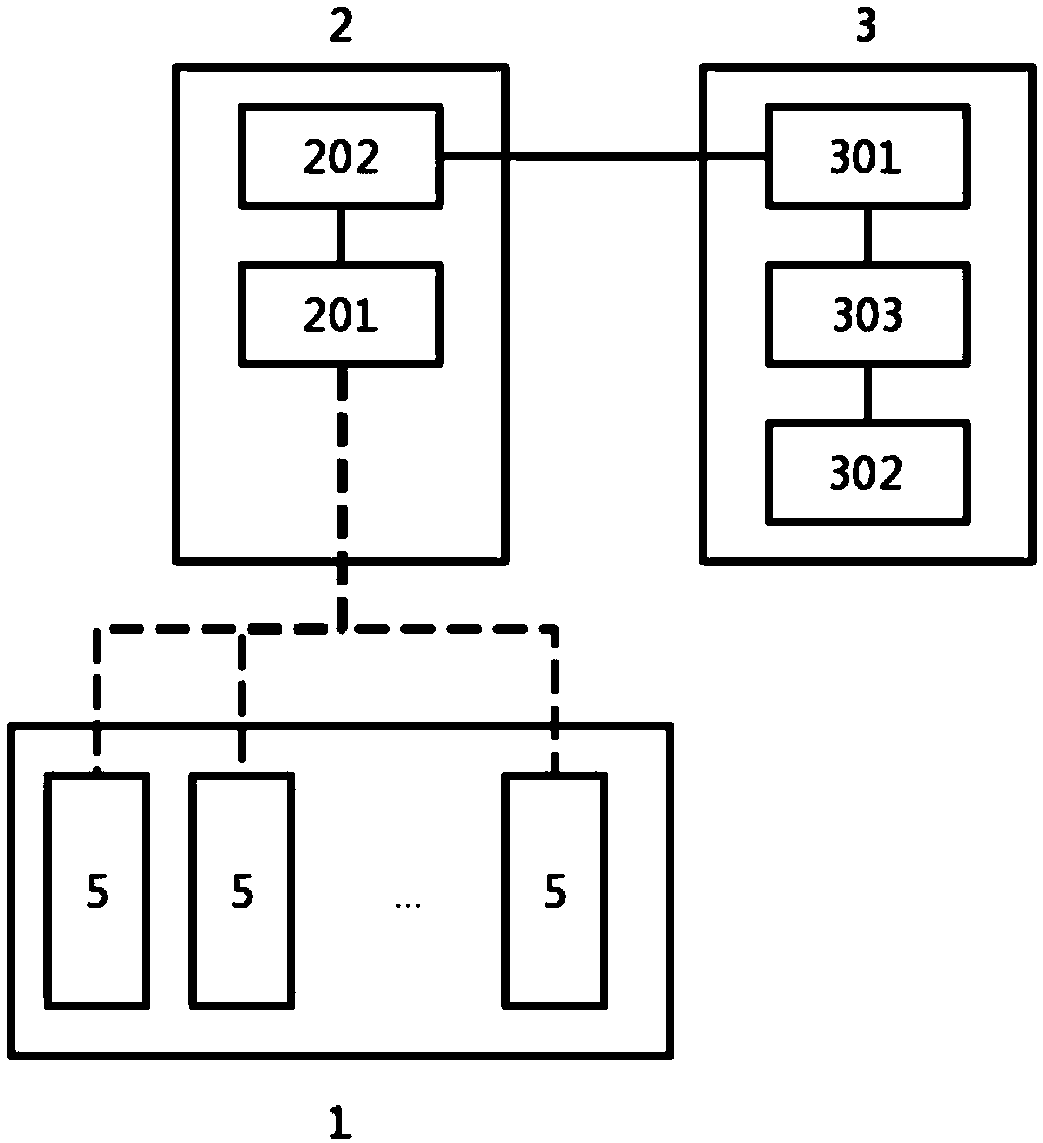

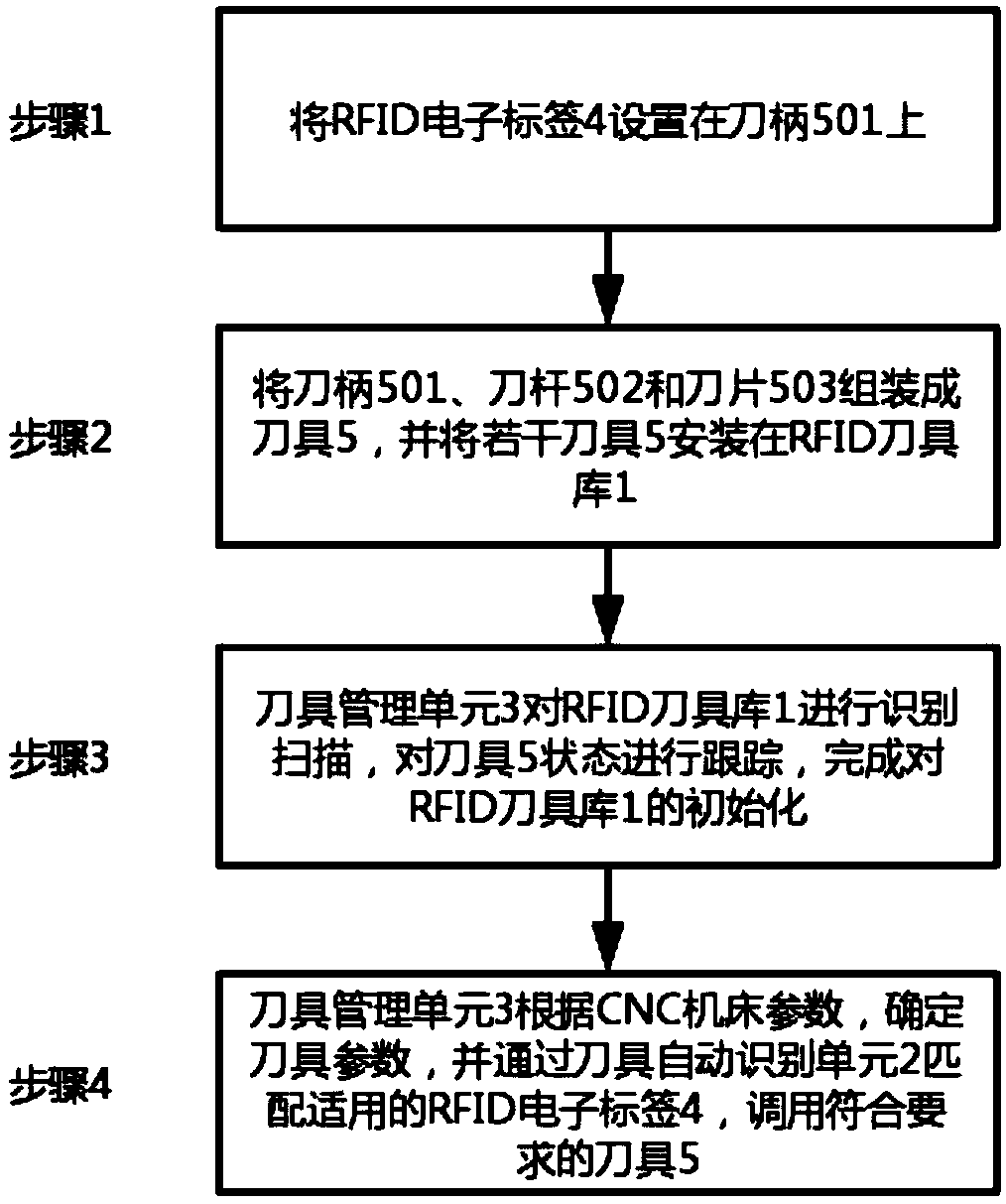

[0030] Please refer to the attached Figure 1-3 , an RFID-based CNC machining center tool automatic identification system, including an RFID tool library 1, a tool automatic identification unit 2, a tool management unit 3 and an RFID electronic tag 4; the tool management unit 3 and the tool automatic identification unit 2 Connected by cables; the RFID tool magazine 1 is connected to the tool automatic identification unit 2 through wireless communication; the RFID electronic tag 4 is arranged on the tool 5, and several of the tools 5 are stored in the RFID tool magazine 1 .

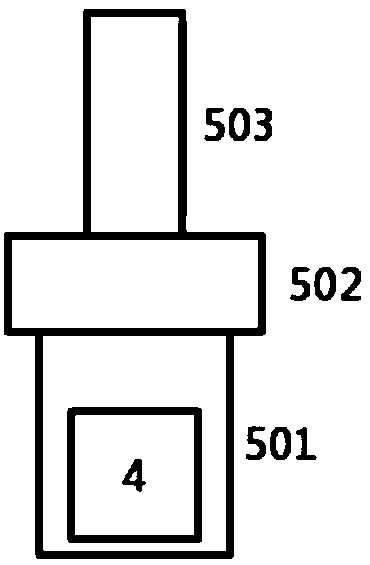

[0031] The knife 5 is composed of a knife handle 501 , a knife rod 502 and a blade 503 ; the RFID electronic tag 4 is set on the knife handle 501 .

[0032] The RFID electronic tag 4 includes a tool number and a seat number.

[0033] The tool management unit 3 is composed of a tool information collection unit 301 , a tool information database 302 and a host computer 303 ; the host computer 303 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com