Mobile relay protection test power supply device

A technology for relay protection and test power supply, which is applied in the direction of output power conversion devices, electrical components, electrical equipment structural parts, etc., and can solve problems such as increasing output power, malfunctioning relay protection, and abnormal DC system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

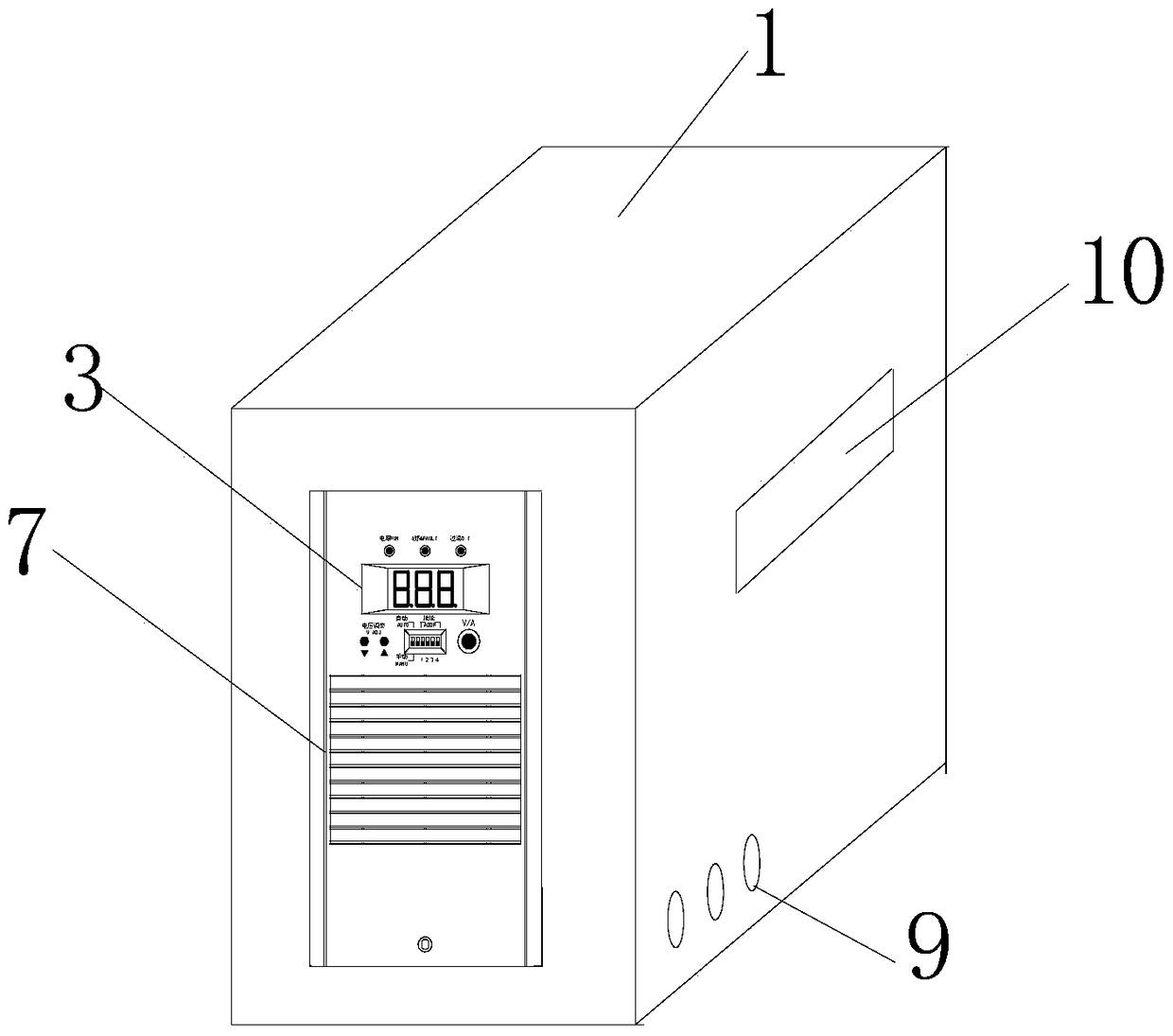

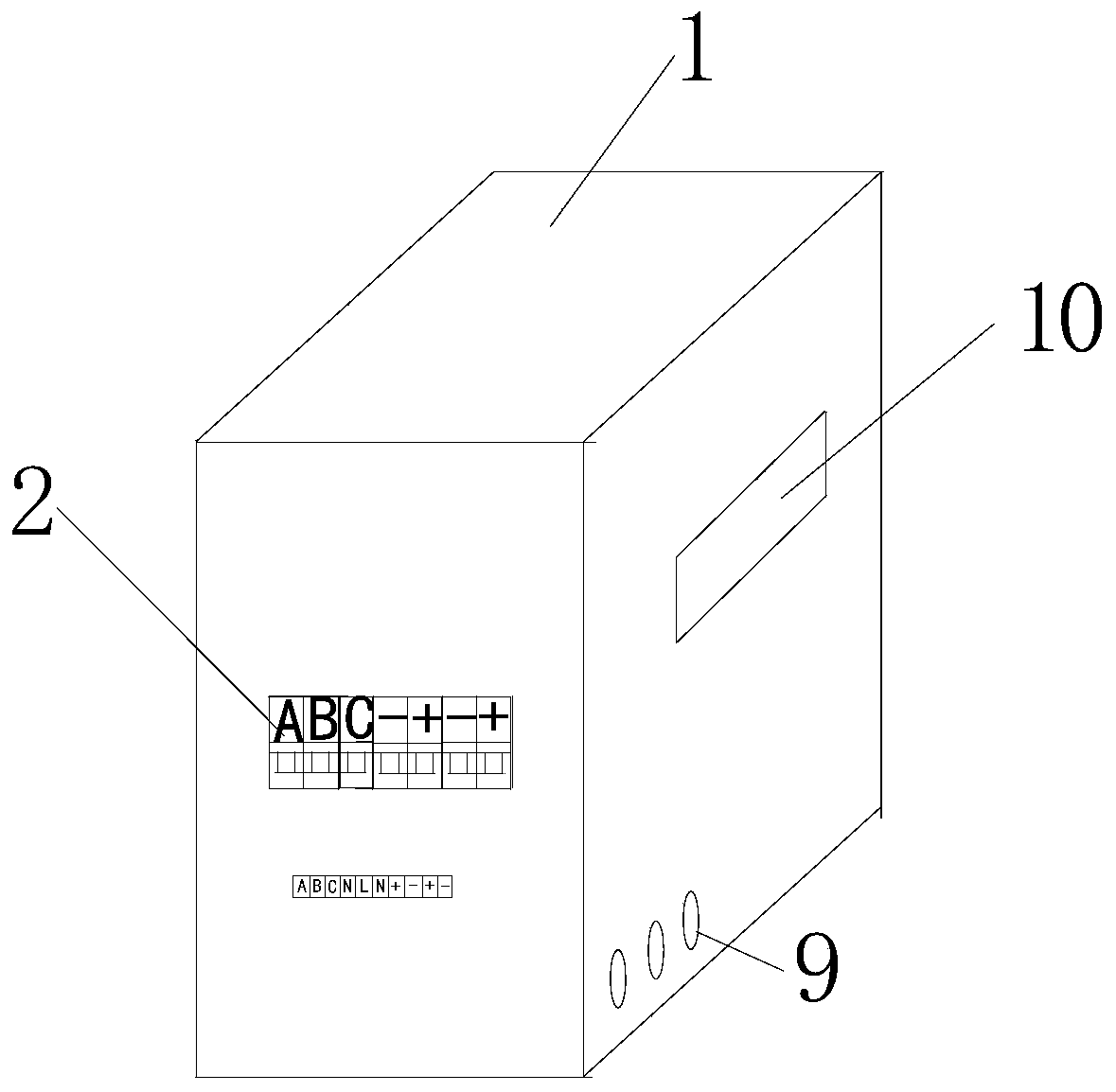

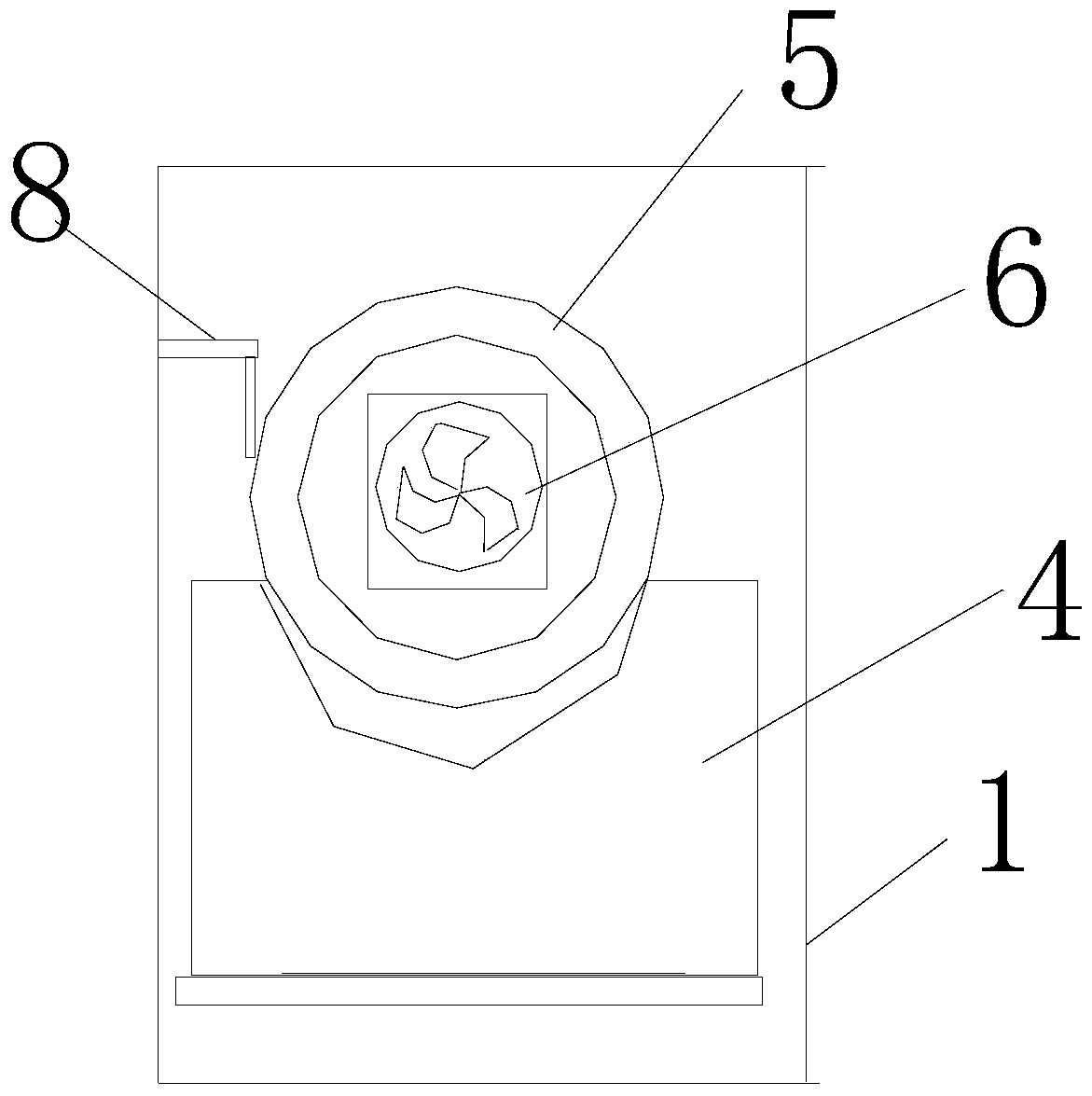

[0022] Such as figure 1 , figure 2 The present invention discloses a mobile relay protection test power supply device as shown, comprising a square housing 1, a control panel 3 is provided on the front of the housing 1, a wiring panel 2 is provided on the back of the housing 1, and a wiring panel 2 is provided on the back of the housing 1. A circuit board is installed in 1, and a rectifier module 4 is installed on the circuit board, such as image 3 As shown, the section of the rectification module 4 is U-shaped. The inside of the housing 1 is also provided with a spiral wiring channel 5. The spiral wiring channel 5 passes through the rectification module 4 and runs through the entire housing 1. The cables in the housing 1 are all laid in the spiral wiring channel 5. There is also a fan 6 inside the casing 1, the fan 6 is facing the center of the spiral wiring channel 5, and a heat dissipation grid 7 is opened under the control panel 3 on the front of the casing 1. A hange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com