Shoe polishing device and method

A technology for leather shoes and shoe polish, which is applied to household cleaning devices, cleaning of boots and shoes, cleaning equipment, etc., can solve problems such as poor safety, and achieve good safety results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

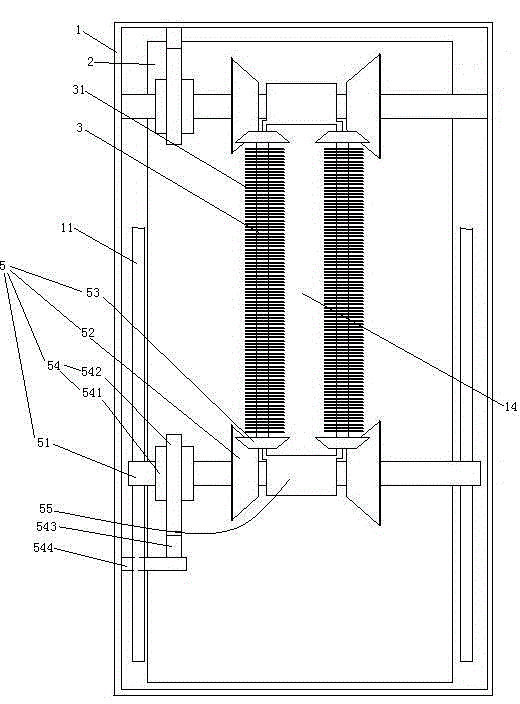

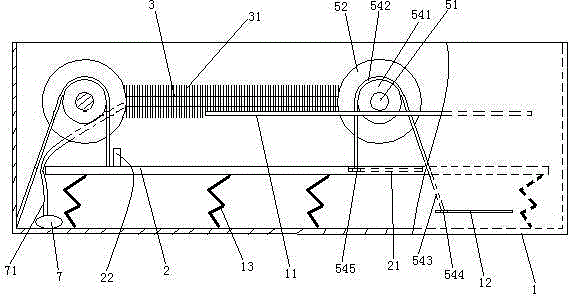

[0026] Embodiment one, see figure 1 , a shoe polishing device, including a frame 1, a pallet 2 and two bristle fixing cables 3.

[0027] Rack 1 is a box structure. The frame 1 is provided with two guide rails 11 . Two guide rails 11 are distributed along the left and right directions. The guide rail 11 extends in the front-rear direction.

[0028] Supporting plate 2 is positioned at the below of bristle fixing cable 3.

[0029] Two bristle fixing cables 3 are distributed along the left and right directions. A shoe inlet 14 is formed between the two bristle fixing cables 3 . The bristle fixing cable 3 extends along the front-back direction. The bristle fixing cable 3 is elastically stretchable, such as a rubber band, an elastic band or a spring. In the initial state, the length (dimension along the front and rear direction) of the shoe inlet 14 is less than 10 cm and the width is less than 3 cm. The bristle fixing cable 3 is connected with a bristle 31 . The bristle fi...

Embodiment 2

[0040] Embodiment two, the difference with embodiment one is:

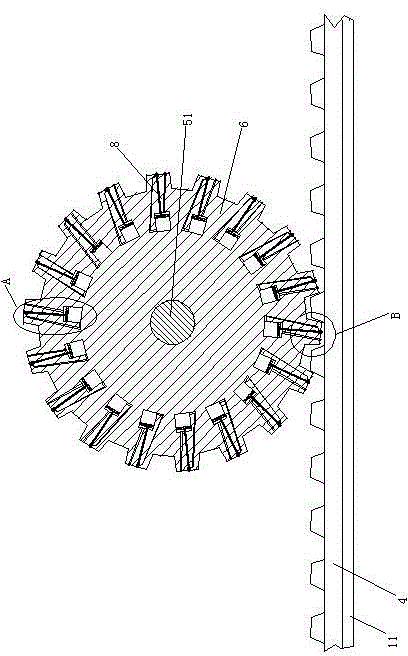

[0041] see image 3 , A rack 4 is provided on the guide rail 11 . The rotating shaft 51 is provided with the travel gear 6 . The rotating shaft 51 is supported by the guide rail 11 through the travel gear 6 meshing with the rack 4 . Several lubricating mechanisms 8 are arranged in the traveling gear 6 . The number of lubricating mechanisms 8 is equal to the number of teeth of the traveling gear 6 .

[0042] see Figure 4 , The lubricating mechanism 8 includes an oil outlet 81 , an air supply port 82 , a sealing head 83 , a first spring 84 , a cylinder 85 and a piston 86 . The oil outlet 81 and the air supply port 82 of the same lubricating mechanism are arranged on the tooth top 61 of the same tooth of the travel gear 6, and only one oil outlet and air supply port of the lubricating mechanism are arranged on the tooth top of the same tooth, that is, in this embodiment The teeth of the lubricating mechanism a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com