Quick-disassembly type internal mixer

A technology of internal mixer and quick disassembly, which is applied in the field of internal mixer, can solve the problems of inconvenient discharge of materials in the internal mixer, failure of normal discharge, high labor cost, etc., and is suitable for large-scale promotion and application, reducing costs and pollution , the effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the structure, features and other purposes of the present invention, the following detailed descriptions are attached with accompanying drawings in conjunction with the attached preferred embodiments. The embodiments illustrated in the drawings are only used to illustrate the technical solutions of the present invention and are not limited this invention.

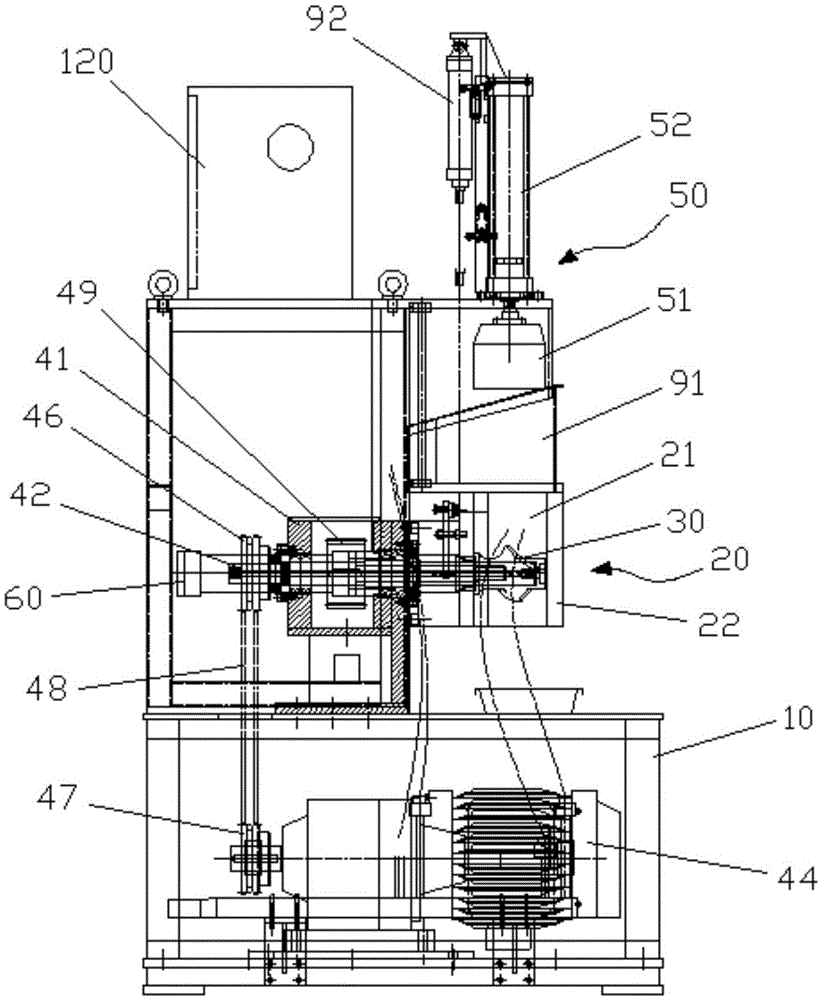

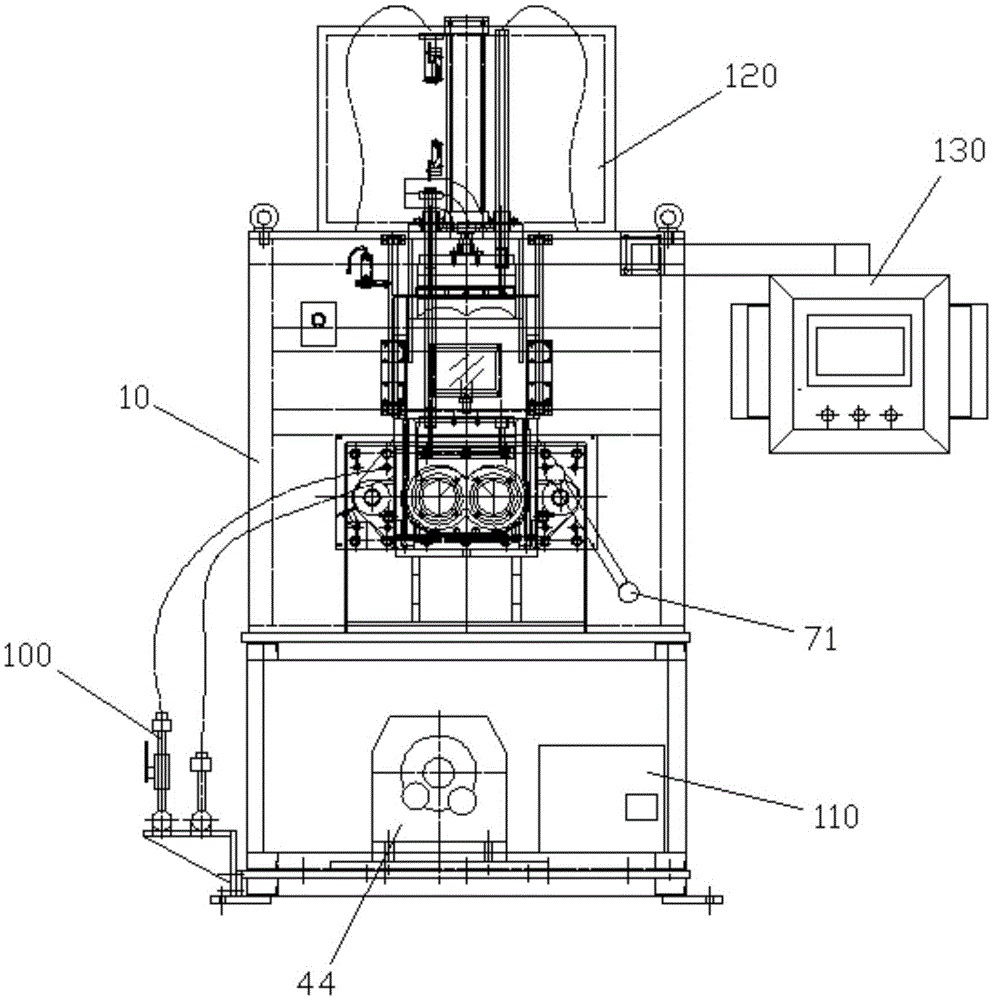

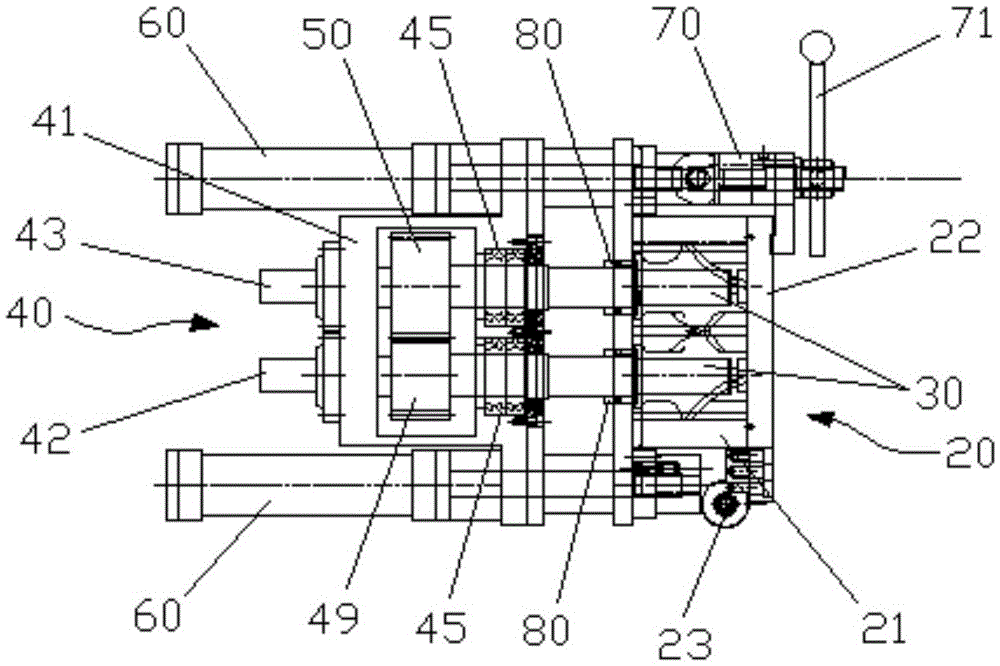

[0024] Reference Figure 1 to Figure 2 As shown, a quick-release internal mixer is provided, which includes a frame 10, a mixing chamber 20 on the frame 10, two mixing rotors 30 located in the mixing chamber 20, and driving the mixing rotor 30 An electric box 120 is provided on the rack 10, and a controller 130 electrically connected to the electric box 120 is installed on one side of the rack 10, and the pressing device 50 is located above the mixing chamber 20.

[0025] Among them, a heating system and a cooling runner 100 are provided in the internal mixing chamber 20 to provide precise p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com