Self-adaptive bag clamping device

A self-adaptive, bag-clamping technology, applied in packaging and other directions, can solve the problems of complicated replacement and high cost, and achieve the effect of compact overall structure, lower production cost, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention will be further described in conjunction with the accompanying drawings.

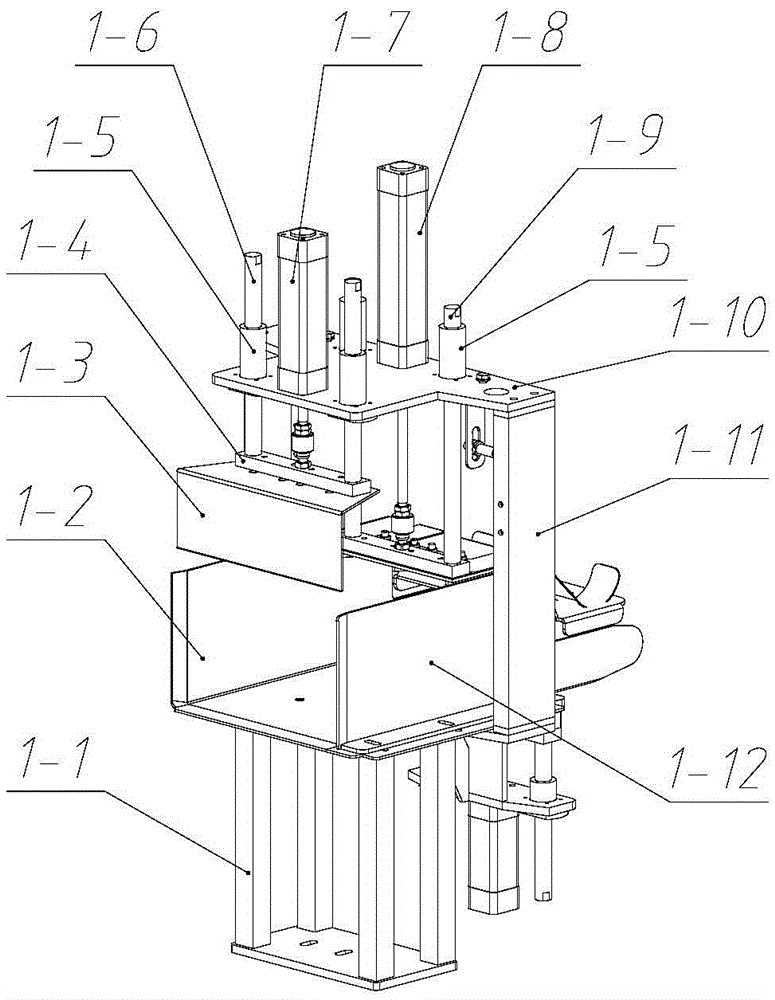

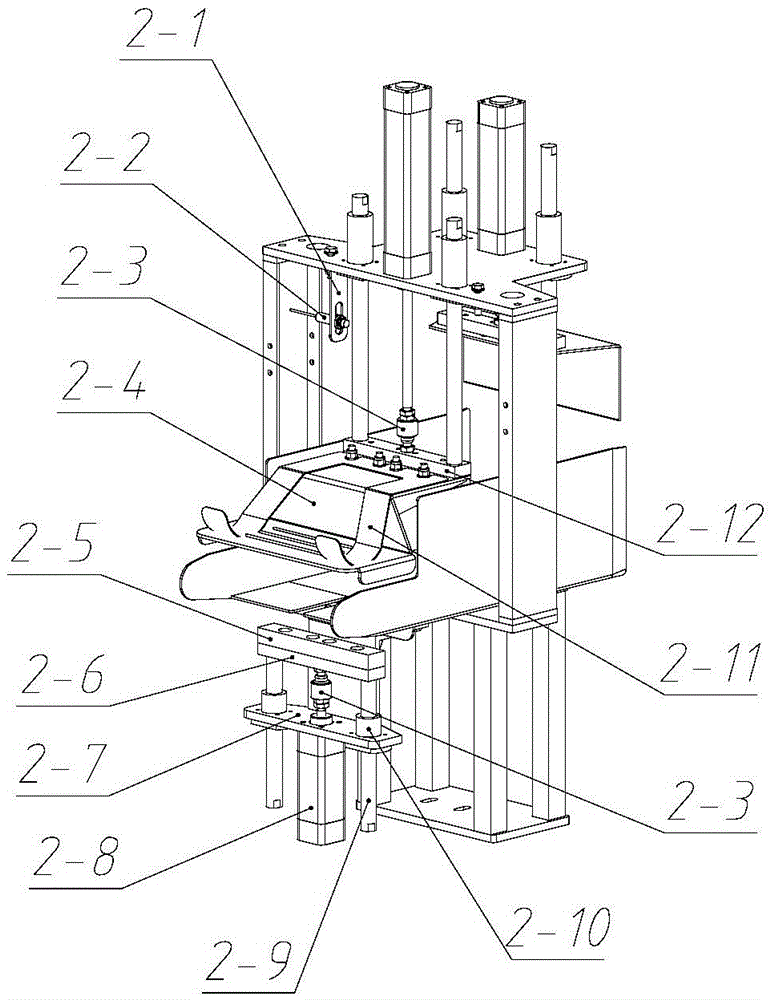

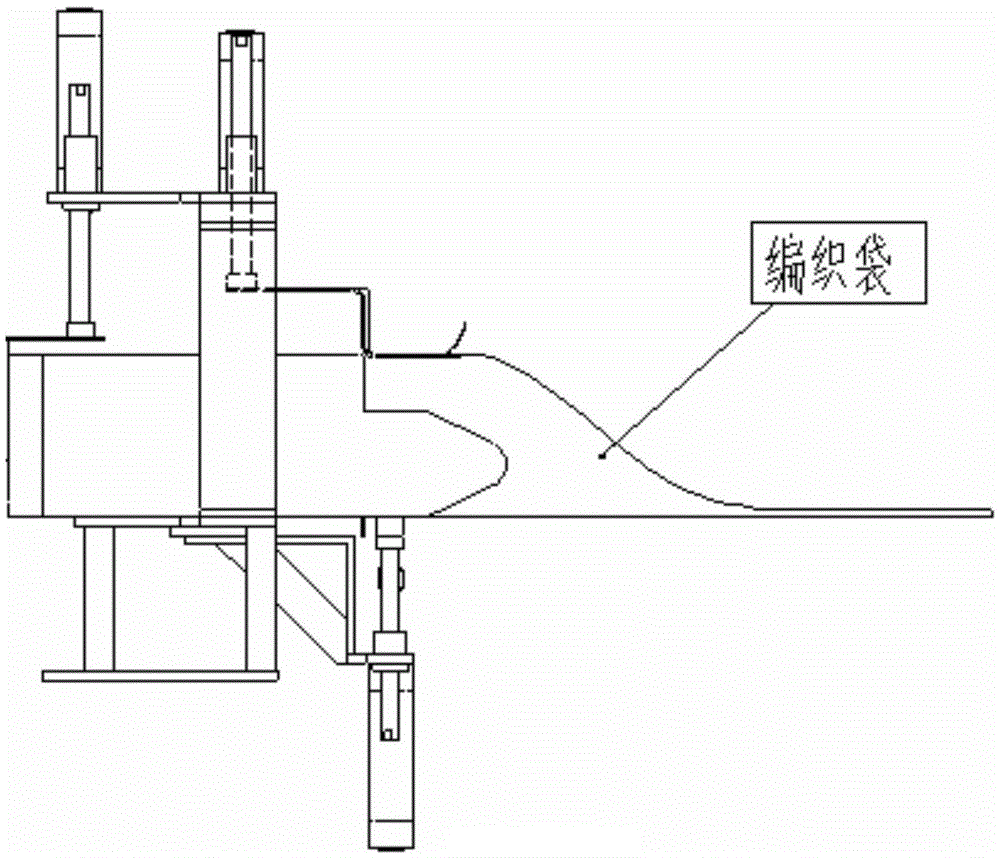

[0021] Such as figure 1 , figure 2 with image 3 As shown, the present invention includes a mounting seat 1-1, a bag holder, an auxiliary baffle plate 1-3, a guide rod connecting plate 1-4, four long flange bearings 1-5, two guide rods 1-6, Auxiliary baffle cylinder 1-7, long bag support cylinder 1-8, two long guide rods 1-9, beam 1-10, two columns 1-11, proximity switch frame 2-1, proximity switch 2-2, Floating joint 2-3, bag supporting plate 2-4, bag pressing bar 2-5, bag pressing guide rod connecting plate 2-6, bag pressing cylinder frame 2-7, bag pressing cylinder 2-8, two bag pressing guides Rod 2-9, two pressure bag guide rod flange bearings 2-10, anti-falling reed 2-11 and guide rod crossbeam 2-12, bag clamping parts include fixed end 1-2, adjustment end 1-12 and bottom plate ; It is characterized in that four long flange bearings 1-5, auxiliary baffle cylinders 1-7 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com