A seamless construction method for ultra-long structures combining sequential and jumping warehouses, intermittent and strengthening

A construction method and combined technology, applied in building construction, building material processing, construction, etc., to control shrinkage and cracking of concrete, speed up construction, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited.

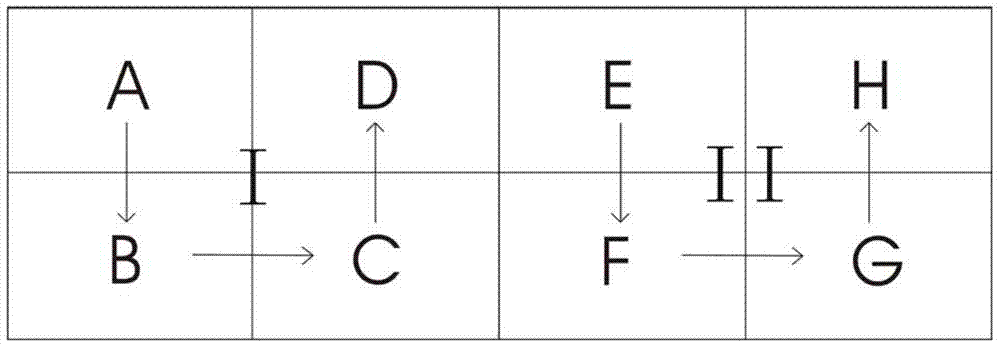

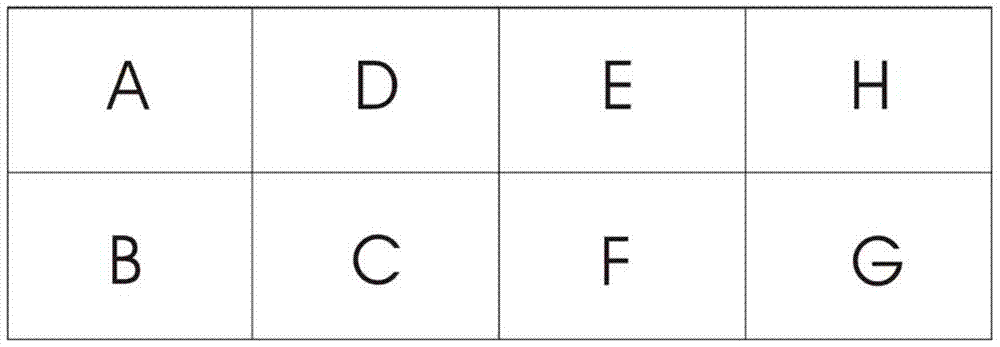

[0022] A seamless construction method for super-long structures that combines sequence and skipping, intermittent and reinforcement, the construction method includes construction organization technology combining sequence and skipping, and construction organization technology combining intermittent and strengthening;

[0023] The combination of sequence and skipping, and the combination of interval and reinforcement refer to the construction method of combining sequence and skipping for adjacent construction sections that meet the shortest intermittent time in concrete pouring construction. For the adjacent construction section using the jump warehouse method, the construction method of intermittent reinforcement belts shall be adopted;

[0024] The seamless construction of super-long structures refers to the method of one-time sequent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com