Netless flexible tapestry brick thermal insulation wall body and construction method thereof

A flexible veneer and thermal insulation wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of blocking moisture evaporation, easy falling off of veneer bricks, hidden dangers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Composite anti-cracking short fiber additive 4%;

[0057] Medium sand 60%;

[0058] Cement 28%.

Embodiment 2

[0060] Composite anti-cracking short fiber additive 1%;

[0062] Medium sand 50%;

[0063] Fine sand 13%;

[0064] Building Lotion 20%.

[0065] The non-network flexible anti-cracking mortar protective layer is close to the outside of the insulation layer, and the above-mentioned composite anti-cracking short fiber additive is alkali-resistant short fiber, mineral fiber or a combination of the two.

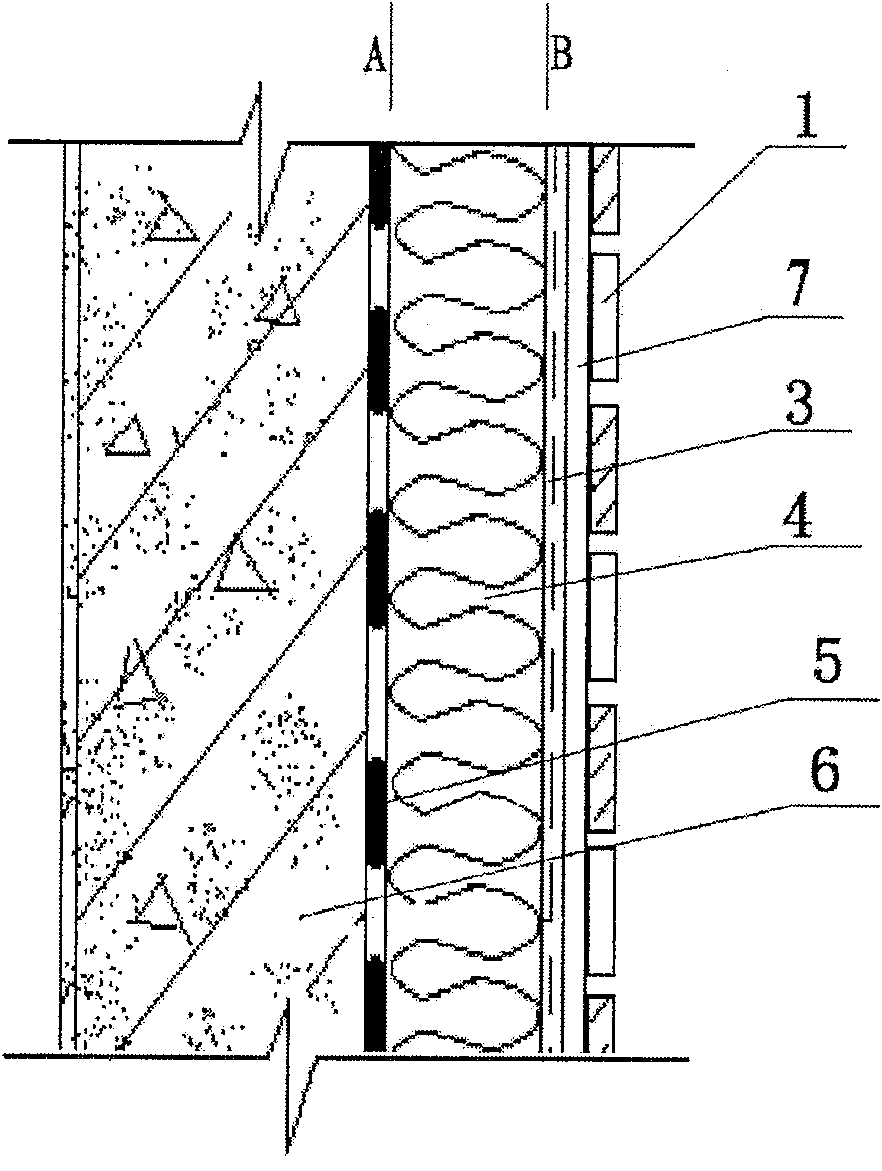

[0066] The construction method of this kind of non-network flexible facing brick insulation wall is as follows:

[0067] Step 1: Grassroots cleaning;

[0068] Step 2: apply the thermal insulation material adhesive layer on the A side of the thermal insulation layer;

[0069] Step 3: Paste the insulation layer on the base layer;

[0070] Step 4: Evenly apply a non-network flexible anti-cracking mortar protective layer on the B side of the insulation layer;

[0071] Step 5: After the non-network flexible anti-cracking mortar protective layer is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com