A self-balancing prefabricated surface, cast-in-place core-filled wall formwork

A prefabricated surface and self-balancing technology, applied to walls, building components, buildings, etc., can solve the problems of increased cost of the main structure, low strength of filled walls, and increased cost of filled walls, so as to save materials, save labor, and reduce self-weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

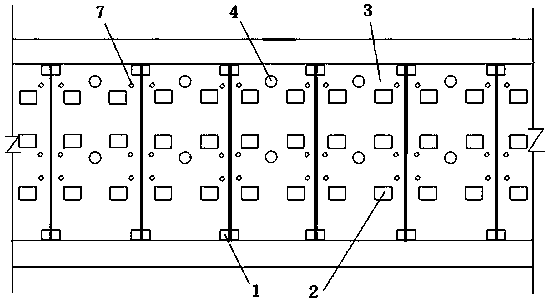

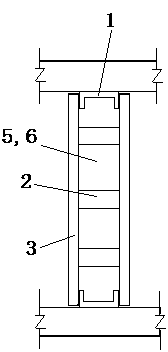

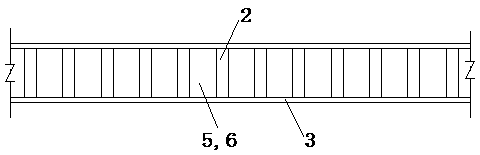

[0042] like Figure 1 to Figure 3 As shown, the prefabricated module frame components: the surface of the prefabricated plate 3 (length 2850mm, width 1200mm, thickness 20mm) is attached with glass fiber mesh, the middle and top of the plate are provided with two pouring holes 4 with a diameter of 70mm, and the block connection key 2 ( Length, width 100mm, thickness 80mm) are delivered to the construction site after mass production in the factory assembly line using gypsum materials, and six connecting keys 2 and two prefabricated panels 3 are pasted firmly with adhesive to form a cavity mold, block positioning keys 1. Recycled hard plastic is used for mass production in the factory assembly line (trough section, length 200mm, width 80mm, 180mm, thickness 80mm, wall thickness 10mm). The force cable 9 is a closed loop fiber cable and a linear fiber cable (ringed at both ends) connected by a length adjusting device, or a nylon strap.

[0043] Core filling material 6: Set up site...

Embodiment 2

[0049] There are two columns of pull connection holes 7 on the prefabricated plate 3 (3 on one side, such as figure 1 shown), at the junction of the cavity mold (two-sided prefabricated panels 3 bonded to the connecting key 2), the prefabricated panels 3 on both sides (walls) The prefabricated panels 3) on the same side of the body are connected and fixed, and the rest are the same as in Embodiment 1.

Embodiment 3

[0051] On the prefabricated plate 3 of the cavity mold, drill two rows of six pull connection holes 7 in total on the spot, pass the pull connection holes 7 with a straight line applying force cable 9 or iron wire, and clamp the two sides with wooden cylindrical pins. The prefabricated panels 3 (prefabricated panels 3 on both sides of the wall) are pulled together to resist the tension during pouring, refer to Figure 12 . The rest are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com