Underground robot communication control system based on Wifi

A communication control and robot technology, applied in wireless communication, closed-circuit television system, mining equipment, etc., can solve the problems of unusable wireless communication system and affecting the working distance of underground robots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

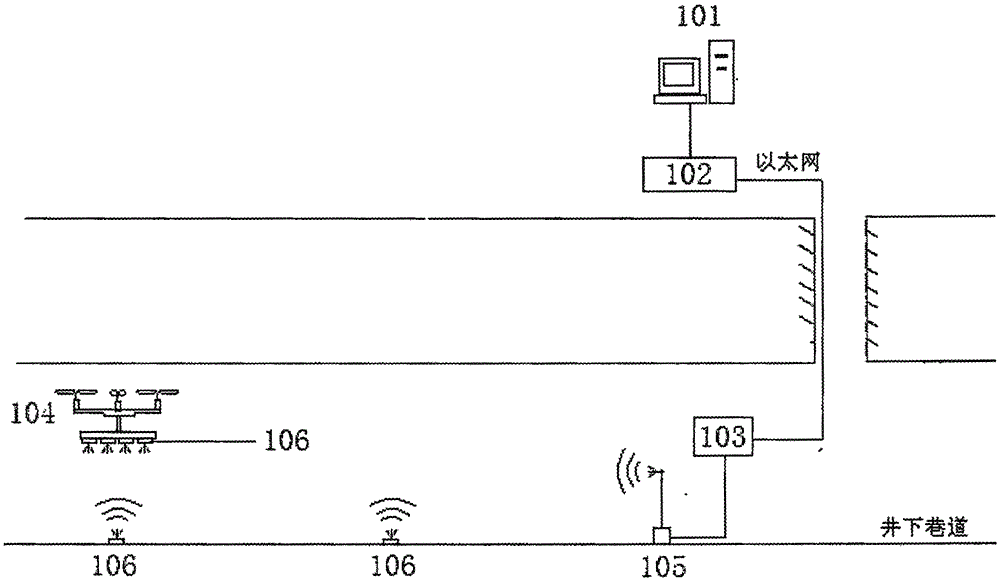

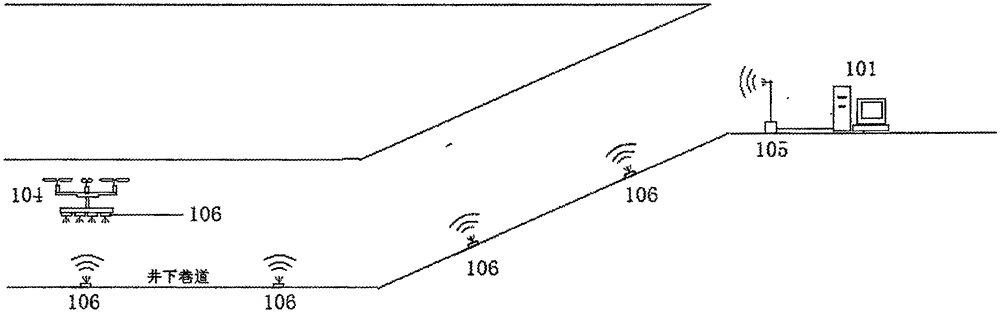

[0021] The specific implementation manner of the communication control system 1 is as figure 1 As shown, the composition includes:

[0022] 1. The robot control device (101), responsible for controlling the downhole robot, receives various data uploaded by the downhole robot through the multi-hop Wifi network and Ethernet, including video or image data, various sensor data, and voice data; The multi-hop Wifi network sends control data and voice data to the underground robot.

[0023] 2. Inoue switch (102), responsible for management and data exchange of all devices connected to the Ethernet.

[0024] 3. The downhole switch (103), responsible for data exchange of all devices connected to the Ethernet in the downhole.

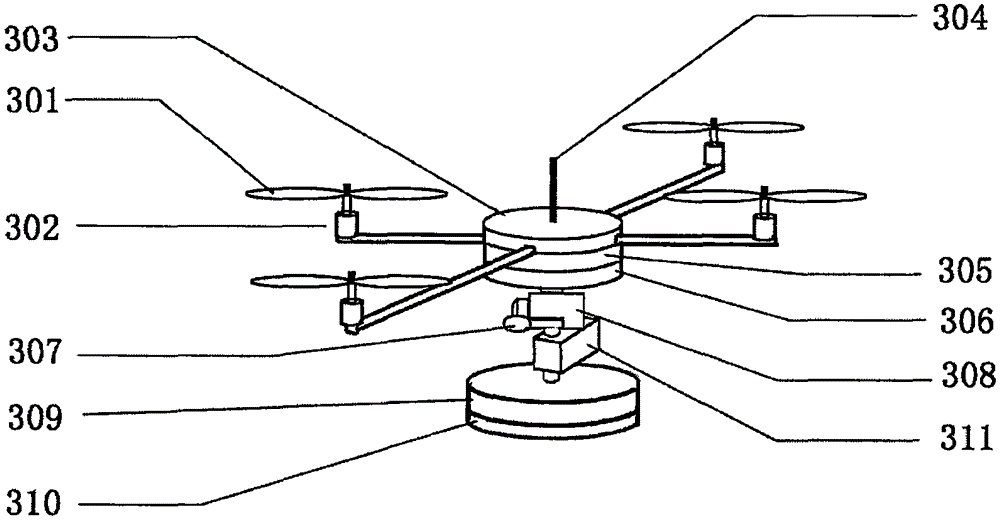

[0025] 4. The underground robot (104) can be a rotor flying robot, or a wheeled, crawler, snake-like robot that travels on the ground, carrying a plurality of Wifi routing devices (106) for distributing nets during travel.

[0026] 5. The Wifi core switch (105...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com